Aramid fiber and Kevlar fiber are both high-strength synthetic fibers known for their exceptional durability and heat resistance, commonly used in ballistic and protective gear. Kevlar, a specific brand of aramid fiber developed by DuPont, offers superior tensile strength and impact resistance, making it ideal for applications requiring enhanced protection. While all Kevlar fibers are aramid fibers, not all aramid fibers possess the exact properties of Kevlar, as variations exist depending on manufacturing processes and fiber formulations.

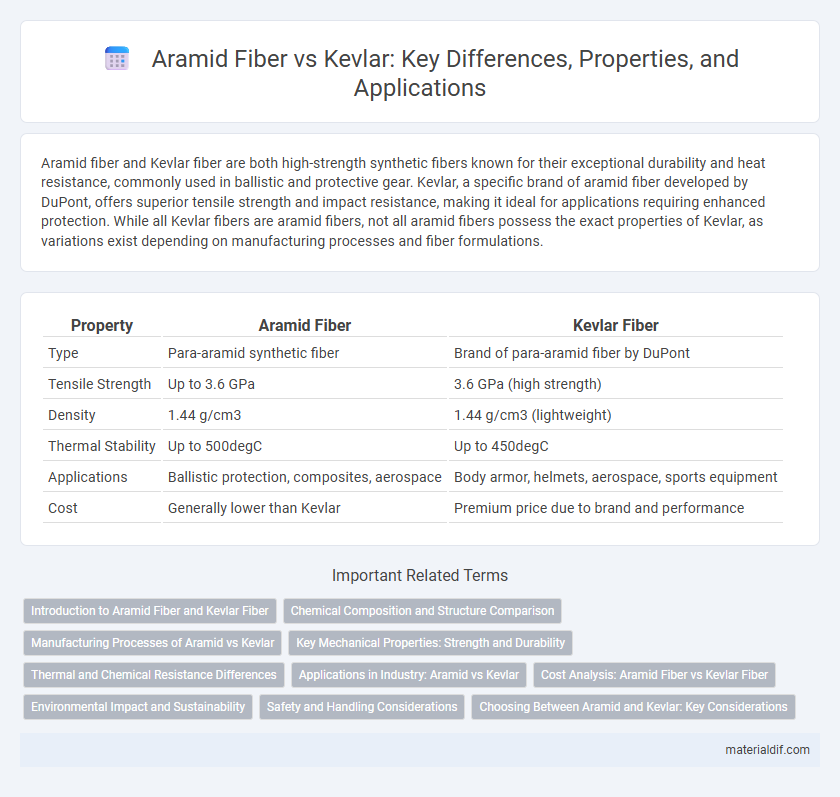

Table of Comparison

| Property | Aramid Fiber | Kevlar Fiber |

|---|---|---|

| Type | Para-aramid synthetic fiber | Brand of para-aramid fiber by DuPont |

| Tensile Strength | Up to 3.6 GPa | 3.6 GPa (high strength) |

| Density | 1.44 g/cm3 | 1.44 g/cm3 (lightweight) |

| Thermal Stability | Up to 500degC | Up to 450degC |

| Applications | Ballistic protection, composites, aerospace | Body armor, helmets, aerospace, sports equipment |

| Cost | Generally lower than Kevlar | Premium price due to brand and performance |

Introduction to Aramid Fiber and Kevlar Fiber

Aramid fiber, a class of heat-resistant and strong synthetic fibers, is widely used in aerospace, military, and industrial applications due to its exceptional strength-to-weight ratio and thermal stability. Kevlar fiber, a type of aramid fiber developed by DuPont, outperforms many traditional materials with its high tensile strength, impact resistance, and lightweight characteristics, making it ideal for ballistic and protective gear. Both fibers are composed of aromatic polyamide chains, but Kevlar's tightly packed molecular structure enhances durability and cut resistance compared to general aramid variants.

Chemical Composition and Structure Comparison

Aramid fiber and Kevlar fiber both belong to the aromatic polyamide family, composed primarily of para-phenylene terephthalamide units, which contribute to their high strength and thermal stability. Kevlar is a brand-specific type of aramid fiber characterized by a tightly packed, highly crystalline structure that enhances its tensile strength and impact resistance. The molecular chains in aramid fibers are aligned in a rigid, rod-like fashion, facilitating strong hydrogen bonding and van der Waals forces, which provide exceptional mechanical properties and chemical resistance in both cases.

Manufacturing Processes of Aramid vs Kevlar

Aramid fibers, including Kevlar, are produced through a specialized solution spinning process where liquid crystalline polymers are extruded and chemically treated to form strong, heat-resistant fibers. Kevlar, a trademarked aramid fiber by DuPont, utilizes a specific poly-paraphenylene terephthalamide polymer and a carefully controlled wet-spinning process to achieve its superior tensile strength and durability. The key manufacturing distinction lies in Kevlar's proprietary polymer structure and precise processing parameters that optimize molecular orientation and fiber crystallinity compared to generic aramid fibers.

Key Mechanical Properties: Strength and Durability

Aramid fiber and Kevlar fiber both exhibit exceptional strength and durability, with Kevlar being a well-known trade name for a specific type of aramid fiber developed by DuPont. Kevlar offers high tensile strength, five times stronger than steel on an equal weight basis, and superior resistance to impact and abrasion, making it ideal for ballistic and protective applications. Aramid fibers, including Kevlar, provide excellent thermal stability and resistance to fatigue, ensuring long-lasting performance in demanding environments.

Thermal and Chemical Resistance Differences

Aramid fiber and Kevlar fiber both belong to the aramid family but exhibit distinct thermal and chemical resistance properties. Kevlar offers superior thermal stability, maintaining structural integrity up to approximately 450degC, while general aramid fibers typically withstand temperatures around 370degC. In terms of chemical resistance, Kevlar resists many organic solvents and oils but degrades when exposed to strong acids and bases, whereas other aramid fibers may show variable resistance depending on their specific molecular composition.

Applications in Industry: Aramid vs Kevlar

Aramid fibers and Kevlar fibers are both high-performance materials used extensively in industrial applications requiring exceptional strength and durability. Kevlar, a specific brand of aramid fiber, is especially favored in ballistic and protective gear, such as bulletproof vests, due to its outstanding impact resistance and energy absorption properties. General aramid fibers find broader use in aerospace, automotive components, and composite reinforcements where thermal stability and lightweight strength are critical.

Cost Analysis: Aramid Fiber vs Kevlar Fiber

Aramid fiber and Kevlar fiber differ significantly in cost due to their manufacturing processes and performance characteristics. Kevlar, a specific brand of aramid fiber produced by DuPont, generally commands a higher price because of its superior tensile strength and widespread industrial applications. Cost analysis reveals that while both offer excellent strength-to-weight ratios, Kevlar's premium pricing is justified in high-performance sectors such as aerospace and ballistic protection, whereas generic aramid fiber provides a more budget-friendly option for less demanding uses.

Environmental Impact and Sustainability

Aramid fibers, including Kevlar, are derived from non-renewable petroleum sources, contributing to environmental concerns due to energy-intensive manufacturing processes and limited biodegradability. Kevlar, a specific brand of aramid fiber, has seen advancements in recycling techniques, yet both fibers pose challenges in sustainable disposal compared to natural alternatives. Strategies to improve environmental impact focus on developing bio-based aramids and enhancing recycling methods to reduce landfill accumulation and resource consumption.

Safety and Handling Considerations

Aramid fibers like Kevlar exhibit exceptional strength and heat resistance, making them highly safe for applications requiring impact and abrasion resistance. Handling Kevlar fibers requires care to avoid respiratory exposure to dust or fibers, as inhalation can cause irritation; therefore, protective masks and gloves are recommended during processing. Unlike some synthetic fibers, Kevlar does not melt but decomposes at high temperatures, reducing fire hazards but necessitating controlled cutting and abrasion methods to minimize airborne fiber release.

Choosing Between Aramid and Kevlar: Key Considerations

Choosing between aramid and Kevlar fibers depends on factors such as tensile strength, thermal resistance, and application requirements. Kevlar, a specific type of aramid fiber, offers exceptional impact resistance and is widely used in ballistic and protective gear. Consider project-specific needs like flexibility, weight, and cost when selecting between general aramid fibers and specialized Kevlar variants.

Aramid fiber vs Kevlar fiber Infographic

materialdif.com

materialdif.com