Jute fiber is coarser and less flexible than flax fiber, making it ideal for products like sacks and ropes where strength is crucial. Flax fiber offers superior softness and durability, often used in high-quality textiles and linen production. Both fibers are biodegradable and eco-friendly, but flax has a higher tensile strength and better moisture-wicking properties.

Table of Comparison

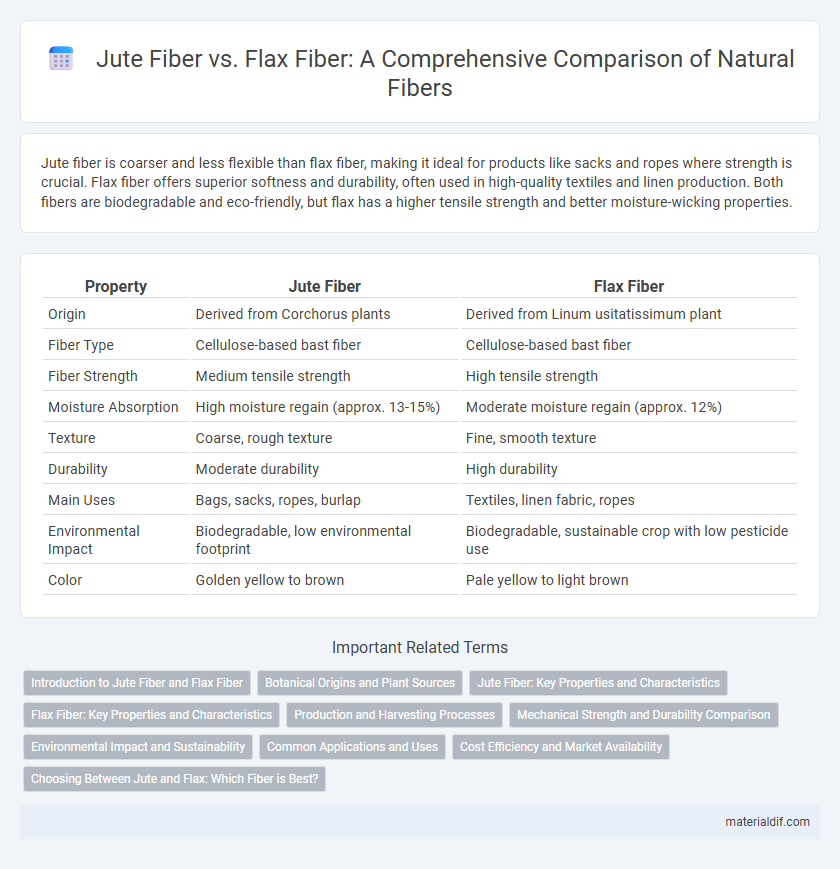

| Property | Jute Fiber | Flax Fiber |

|---|---|---|

| Origin | Derived from Corchorus plants | Derived from Linum usitatissimum plant |

| Fiber Type | Cellulose-based bast fiber | Cellulose-based bast fiber |

| Fiber Strength | Medium tensile strength | High tensile strength |

| Moisture Absorption | High moisture regain (approx. 13-15%) | Moderate moisture regain (approx. 12%) |

| Texture | Coarse, rough texture | Fine, smooth texture |

| Durability | Moderate durability | High durability |

| Main Uses | Bags, sacks, ropes, burlap | Textiles, linen fabric, ropes |

| Environmental Impact | Biodegradable, low environmental footprint | Biodegradable, sustainable crop with low pesticide use |

| Color | Golden yellow to brown | Pale yellow to light brown |

Introduction to Jute Fiber and Flax Fiber

Jute fiber, derived from the Corchorus plant, is known for its coarse texture, high tensile strength, and eco-friendly biodegradability, making it ideal for products like sacks, ropes, and geotextiles. Flax fiber, obtained from the Linum usitatissimum plant, features finer, smoother strands with superior moisture-wicking and durability properties, commonly used in linen textiles and industrial applications. Both fibers offer sustainable alternatives to synthetic materials, but their distinct botanical sources and physical characteristics determine their specific uses and processing methods.

Botanical Origins and Plant Sources

Jute fiber originates from the Corchorus genus, primarily Corchorus olitorius and Corchorus capsularis, native to South Asia and extensively cultivated in Bangladesh and India. Flax fiber is derived from the Linum usitatissimum plant, belonging to the Linaceae family, widely grown in Europe, Canada, and Russia for its strong bast fibers. Both fibers are bast fibers, but jute stems are thicker and coarser compared to the finer, more flexible flax stems used in high-quality linen production.

Jute Fiber: Key Properties and Characteristics

Jute fiber is a natural bast fiber known for its high tensile strength, durability, and biodegradability, making it ideal for eco-friendly packaging and textiles. It exhibits excellent moisture absorbency and breathability, which contributes to its widespread use in agriculture as sacks and mats. The fiber's coarse texture and golden sheen differentiate it from flax, which is finer and has a smoother, shinier appearance.

Flax Fiber: Key Properties and Characteristics

Flax fiber, derived from the flax plant (Linum usitatissimum), is renowned for its exceptional strength, durability, and smooth texture, making it ideal for textile and composite applications. It exhibits high moisture-wicking capabilities, excellent breathability, and natural resistance to bacterial growth, contributing to comfort and hygiene in fabrics. The fiber's ability to be finely spun and its low elastic recovery enhance its use in linen production, offering a sustainable and biodegradable alternative to synthetic fibers.

Production and Harvesting Processes

Jute fiber is primarily harvested from the stem of the Corchorus plant through water retting, which involves submerging stalks in water to separate fibers, a process taking approximately two to three weeks. Flax fiber, derived from the Linum usitatissimum plant, uses dew retting, where stalks are spread on fields to undergo microbial degradation, resulting in finer fibers suitable for high-quality textiles. Jute production is more labor-intensive with higher water usage, whereas flax harvesting demands precise timing and climatic conditions to optimize fiber strength and length.

Mechanical Strength and Durability Comparison

Jute fiber exhibits moderate mechanical strength with tensile strength ranging between 400-800 MPa, making it suitable for applications requiring flexibility but limited durability under heavy stress. Flax fiber surpasses jute in mechanical performance, offering tensile strength up to 1500 MPa and higher stiffness, which contributes to superior durability and longevity in composite materials. The enhanced strength and durability of flax fiber make it ideal for high-performance textiles and reinforced composites, while jute remains preferred for eco-friendly packaging and low-stress applications.

Environmental Impact and Sustainability

Jute fiber and flax fiber both offer environmentally friendly options, but jute fiber has a lower carbon footprint due to its rapid growth and minimal water requirements compared to flax. Jute cultivation enhances soil fertility through crop rotation and requires fewer pesticides, whereas flax demands more intensive agricultural inputs. Both fibers are biodegradable and renewable, yet the sustainability of jute fiber is favored for its efficient land use and carbon sequestration properties.

Common Applications and Uses

Jute fiber is commonly used in making sacks, ropes, carpets, and upholstery due to its strong, durable, and coarse texture, making it ideal for industrial and agricultural applications. Flax fiber, derived from the flax plant, is primarily utilized in the production of linen textiles, high-quality clothing, and composite materials in automotive and construction industries because of its fine, smooth texture and superior tensile strength. Both fibers serve important roles in eco-friendly products, with jute favored for heavy-duty packaging and flax prized for lightweight, breathable fabrics.

Cost Efficiency and Market Availability

Jute fiber is generally more cost-efficient than flax fiber due to its lower production and processing costs, making it a preferred choice in large-scale, budget-sensitive applications. Market availability of jute fiber is higher, particularly in South Asia, where production is concentrated, ensuring steady supply and competitive pricing. Flax fiber, while offering superior strength and quality, tends to be costlier and less widely available, limiting its use to niche markets that demand premium materials.

Choosing Between Jute and Flax: Which Fiber is Best?

Jute fiber offers durability and affordability, making it ideal for products like sacks, carpets, and upholstery, while flax fiber provides superior strength and a smoother texture, preferred in high-quality textiles and linen fabrics. The environmental impact of jute is lower due to its rapid growth and minimal chemical use, whereas flax requires more intensive processing but yields finer, more breathable fabric. When choosing between jute and flax, consider the end-use application, budget constraints, and desired texture for optimal performance and sustainability.

Jute Fiber vs Flax Fiber Infographic

materialdif.com

materialdif.com