Wet spinning involves extruding a polymer solution into a coagulation bath, where fibers solidify through solvent exchange, producing filaments with high tensile strength and uniformity. Dry spinning forces the polymer solution through a spinneret into warm air, allowing the solvent to evaporate and fibers to form, which is ideal for heat-sensitive materials and results in more porous fibers. Both methods are essential in fiber production, with wet spinning favored for polymers insoluble in volatile solvents and dry spinning suited for polymers soluble in volatile solvents.

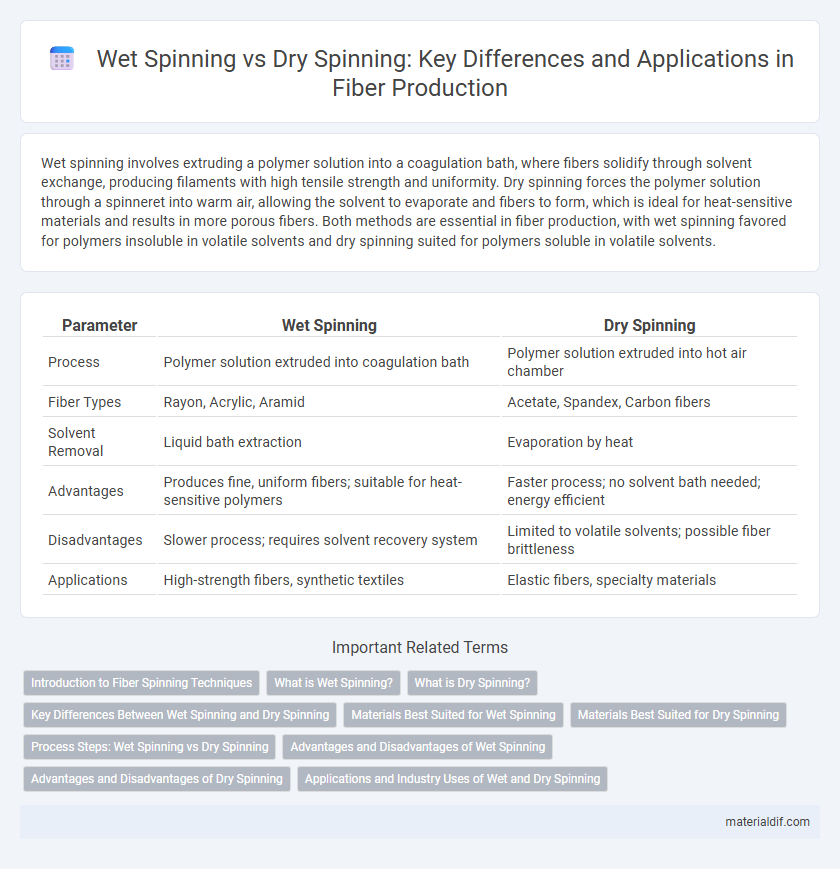

Table of Comparison

| Parameter | Wet Spinning | Dry Spinning |

|---|---|---|

| Process | Polymer solution extruded into coagulation bath | Polymer solution extruded into hot air chamber |

| Fiber Types | Rayon, Acrylic, Aramid | Acetate, Spandex, Carbon fibers |

| Solvent Removal | Liquid bath extraction | Evaporation by heat |

| Advantages | Produces fine, uniform fibers; suitable for heat-sensitive polymers | Faster process; no solvent bath needed; energy efficient |

| Disadvantages | Slower process; requires solvent recovery system | Limited to volatile solvents; possible fiber brittleness |

| Applications | High-strength fibers, synthetic textiles | Elastic fibers, specialty materials |

Introduction to Fiber Spinning Techniques

Wet spinning and dry spinning are foundational fiber spinning techniques used to convert polymer solutions into solid fibers through different coagulation processes. Wet spinning involves extruding the polymer solution into a coagulation bath where fiber solidification occurs, making it suitable for polymers insoluble in volatile solvents. Dry spinning extrudes the polymer solution into a warm air chamber causing solvent evaporation and fiber formation, often applied for polymers soluble in volatile solvents like acetate and acrylic.

What is Wet Spinning?

Wet spinning is a fiber production method where a polymer solution is extruded through spinnerets into a coagulating liquid, causing the polymer to solidify into fibers. This technique is commonly used for fibers like acrylic, rayon, and spandex, enabling the creation of fine, strong filaments with controlled shapes and properties. The process allows for better molecular orientation and fiber uniformity compared to dry spinning.

What is Dry Spinning?

Dry spinning is a fiber production process where a polymer solution is extruded through spinnerets into warm air, causing the solvent to evaporate and solidify the fibers. Commonly used for polymers like cellulose acetate and acrylic, this method enables control over fiber properties such as strength and elongation. Dry spinning is preferred for materials sensitive to moisture and offers advantages in producing uniform and fine fibers.

Key Differences Between Wet Spinning and Dry Spinning

Wet spinning involves extruding a polymer solution into a coagulating bath causing fiber solidification through solvent exchange, while dry spinning ejects the polymer solution into a heated chamber where solvent evaporates to form fibers. Wet spinning is typically used for cellulose, acrylic, and aramid fibers requiring precise control of fiber morphology, whereas dry spinning suits polyvinyl chloride (PVC), acetate, and spandex fibers favoring rapid solvent evaporation. The key differences lie in the fiber formation mechanism, solvent removal process, and applicable polymer types, influencing fiber properties like tensile strength, elongation, and uniformity.

Materials Best Suited for Wet Spinning

Wet spinning is ideal for materials that are insoluble in common solvents but can be dissolved in non-volatile liquids, such as viscose, acrylic, and aramid fibers. This process is favored for producing high-strength fibers like spandex and certain cellulose derivatives due to its ability to maintain polymer chain alignment during coagulation in a liquid bath. Fibers spun wet often exhibit superior tensile properties and fine filament formation, making wet spinning essential for specialty fibers requiring precise molecular orientation.

Materials Best Suited for Dry Spinning

Dry spinning is best suited for polymers such as cellulose acetate, triacetate, and certain acrylics that dissolve in volatile solvents and solidify upon solvent evaporation. Materials like polyvinyl chloride (PVC) and spandex are also commonly processed through dry spinning due to their solubility characteristics and fiber formation properties. This method offers precise control over fiber morphology and is ideal for producing fibers with high strength and fine denier.

Process Steps: Wet Spinning vs Dry Spinning

Wet spinning involves extruding a polymer solution through a spinneret into a coagulation bath, where the fiber solidifies by precipitation, commonly used for fibers like rayon and acrylic. Dry spinning requires the polymer solution to be extruded into a heated chamber, causing solvent evaporation and fiber solidification, typically applied in producing acetate and spandex fibers. Both processes transform polymer solutions into solid fibers but differ in solidification mechanisms: coagulation in wet spinning and solvent evaporation in dry spinning.

Advantages and Disadvantages of Wet Spinning

Wet spinning allows the production of fibers with superior tensile strength and uniformity by extruding polymer solutions into coagulation baths, ideal for acrylic and rayon fibers. Its advantages include excellent fiber quality and the ability to spin polymers that cannot be melted, but disadvantages involve slower production rates and higher operational costs due to solvent recovery and complex equipment. The process also requires careful handling of hazardous chemicals, increasing environmental and safety concerns compared to dry spinning methods.

Advantages and Disadvantages of Dry Spinning

Dry spinning offers advantages such as greater control over fiber morphology and the ability to produce fibers from thermally sensitive polymers without degradation. Disadvantages include higher energy consumption and slower fiber production rates compared to wet spinning, limiting its efficiency for large-scale manufacturing. This method is preferred for polymers soluble in volatile solvents, enabling fine control over fiber diameter and surface properties.

Applications and Industry Uses of Wet and Dry Spinning

Wet spinning is predominantly used for fibers such as acrylic, rayon, and spandex, which require solvents to solidify the polymer and is common in the textile and medical industries for producing high-strength, flexible fibers in surgical sutures and hosiery. Dry spinning suits thermoplastic polymers like acetate and triacetate, favored in fashion fabrics and filtration materials due to its efficiency in quickly evaporating solvents and producing fine, uniform fibers. Both techniques play crucial roles in industries such as automotive, where fiber reinforcement improves composites, and in filtration systems where specific fiber properties are essential.

Wet Spinning vs Dry Spinning Infographic

materialdif.com

materialdif.com