Thermoset fibers are characterized by their irreversible curing process, which provides exceptional heat resistance and structural integrity, making them ideal for high-performance applications. Thermoplastic fibers can be melted and reshaped multiple times, offering greater flexibility, recyclability, and ease of processing compared to thermoset fibers. Choosing between thermoset and thermoplastic fibers depends on the specific requirements for durability, thermal stability, and environmental impact.

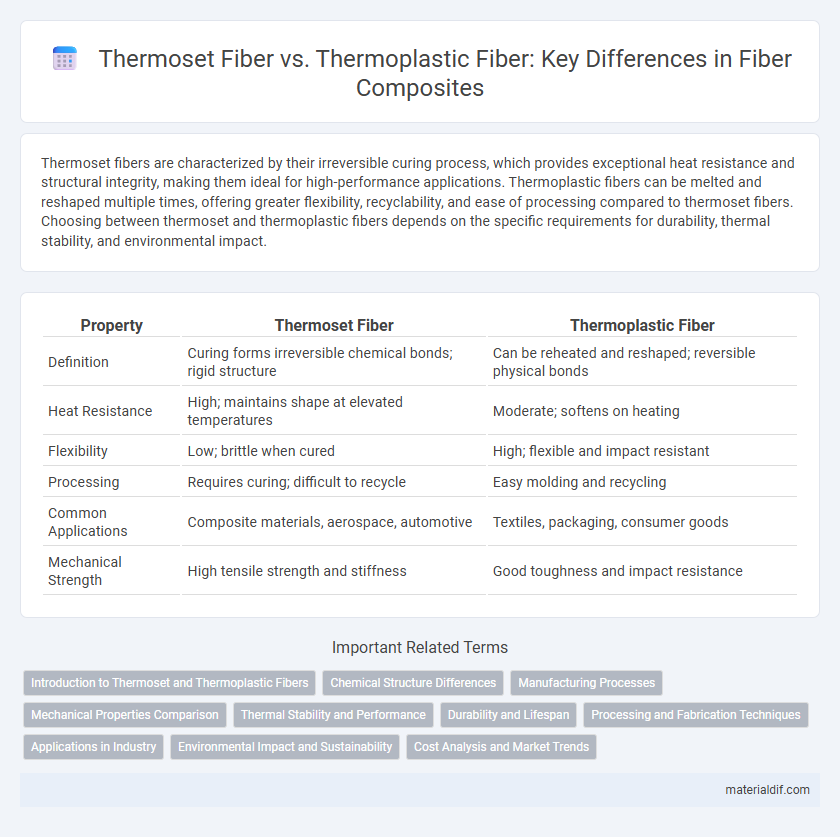

Table of Comparison

| Property | Thermoset Fiber | Thermoplastic Fiber |

|---|---|---|

| Definition | Curing forms irreversible chemical bonds; rigid structure | Can be reheated and reshaped; reversible physical bonds |

| Heat Resistance | High; maintains shape at elevated temperatures | Moderate; softens on heating |

| Flexibility | Low; brittle when cured | High; flexible and impact resistant |

| Processing | Requires curing; difficult to recycle | Easy molding and recycling |

| Common Applications | Composite materials, aerospace, automotive | Textiles, packaging, consumer goods |

| Mechanical Strength | High tensile strength and stiffness | Good toughness and impact resistance |

Introduction to Thermoset and Thermoplastic Fibers

Thermoset fibers are composed of polymers that undergo irreversible chemical cross-linking during curing, resulting in rigid, heat-resistant materials ideal for high-performance applications such as aerospace and automotive industries. Thermoplastic fibers consist of polymers that can be repeatedly melted and reshaped without altering their chemical structure, offering excellent recyclability, flexibility, and impact resistance for use in textiles and composite materials. The fundamental difference lies in thermoset fibers' permanent three-dimensional network versus thermoplastic fibers' linear or branched molecular chains.

Chemical Structure Differences

Thermoset fibers possess a cross-linked chemical structure formed through irreversible curing processes, resulting in a rigid and heat-resistant network. Thermoplastic fibers, composed of linear or branched polymers without cross-links, soften upon heating and can be remolded multiple times. This fundamental difference in chemical bonding impacts their thermal stability, mechanical properties, and recyclability in fiber applications.

Manufacturing Processes

Thermoset fibers are produced through a curing process that involves irreversible chemical cross-linking, resulting in a rigid and heat-resistant structure, commonly made from epoxy or phenolic resins. Thermoplastic fibers are manufactured by melting and extruding polymers like nylon, polyester, or polypropylene, allowing them to be reshaped upon reheating, facilitating recyclability and faster production cycles. The thermoset manufacturing process requires controlled heat and pressure to initiate curing, while thermoplastics rely on extrusion and cooling without chemical changes, making thermoplastics more suitable for high-volume, cost-effective manufacturing.

Mechanical Properties Comparison

Thermoset fibers exhibit superior thermal stability and dimensional retention due to their cross-linked polymer structure, resulting in higher tensile strength and stiffness compared to thermoplastic fibers. Thermoplastic fibers, made from linear or branched polymers, offer better impact resistance and flexibility but typically have lower heat resistance and mechanical strength. The choice between thermoset and thermoplastic fibers depends on application requirements, with thermoset favored for high-performance composites requiring rigidity and thermoplastics preferred for versatile, impact-tolerant materials.

Thermal Stability and Performance

Thermoset fibers exhibit superior thermal stability due to their cross-linked polymer structure, enabling them to maintain integrity and mechanical properties at higher temperatures compared to thermoplastic fibers. Unlike thermoplastics, which soften and deform upon heating, thermoset fibers resist melting and exhibit enhanced dimensional stability under thermal stress. This makes thermoset fibers ideal for high-performance applications requiring prolonged exposure to elevated temperatures and harsh environments.

Durability and Lifespan

Thermoset fibers offer superior durability and a longer lifespan due to their cross-linked polymer structure, which provides excellent resistance to heat, chemicals, and deformation. Thermoplastic fibers, while more flexible and easier to recycle, tend to have lower thermal stability and may degrade faster under prolonged exposure to harsh environmental conditions. The enhanced mechanical strength and chemical resistance of thermoset fibers make them ideal for applications requiring long-term stability and high-performance durability.

Processing and Fabrication Techniques

Thermoset fibers undergo irreversible curing through cross-linking during processing, resulting in rigid, heat-resistant composites ideal for high-performance applications requiring structural integrity. Thermoplastic fibers soften on heating and solidify upon cooling, allowing for repeated reshaping and simpler fabrication techniques like melt spinning, injection molding, and thermoforming. This reversible processing makes thermoplastic fibers suitable for mass production with enhanced recyclability and faster cycle times.

Applications in Industry

Thermoset fibers, known for their high thermal stability and chemical resistance, are widely used in aerospace, automotive, and electronics industries where durability under extreme conditions is critical. Thermoplastic fibers, valued for their recyclability and flexibility, find extensive applications in packaging, textiles, and lightweight automotive components. Industrial sectors increasingly favor thermoplastic fibers for sustainable manufacturing, while thermoset fibers remain essential for structural and high-performance applications.

Environmental Impact and Sustainability

Thermoset fibers, composed of cross-linked polymer chains, exhibit high durability but are difficult to recycle, leading to significant environmental challenges. Thermoplastic fibers can be melted and reprocessed multiple times, offering superior recyclability and lower environmental impact. The sustainability of thermoplastic fibers is enhanced by their potential for circular use and reduced waste generation compared to thermoset fibers.

Cost Analysis and Market Trends

Thermoset fibers, known for their superior heat resistance and structural rigidity, generally incur higher production costs compared to thermoplastic fibers due to complex curing processes and longer manufacturing times. Thermoplastic fibers dominate market trends with increasing demand driven by recyclability, cost-efficiency, and ease of processing, leading to a competitive price advantage in automotive and aerospace industries. Market analysis reveals a growing shift towards thermoplastic fiber composites, propelled by sustainability initiatives and technological advancements reducing lifecycle costs.

Thermoset Fiber vs Thermoplastic Fiber Infographic

materialdif.com

materialdif.com