Roving fiber consists of continuous strands bundled together, offering superior tensile strength and smooth handling for applications like filament winding and pultrusion. Chopped strand fiber, made of short, randomly oriented fibers, enhances reinforcement in molded plastics and increases impact resistance. Choosing between roving fiber and chopped strand depends on the desired mechanical properties and processing methods in composite manufacturing.

Table of Comparison

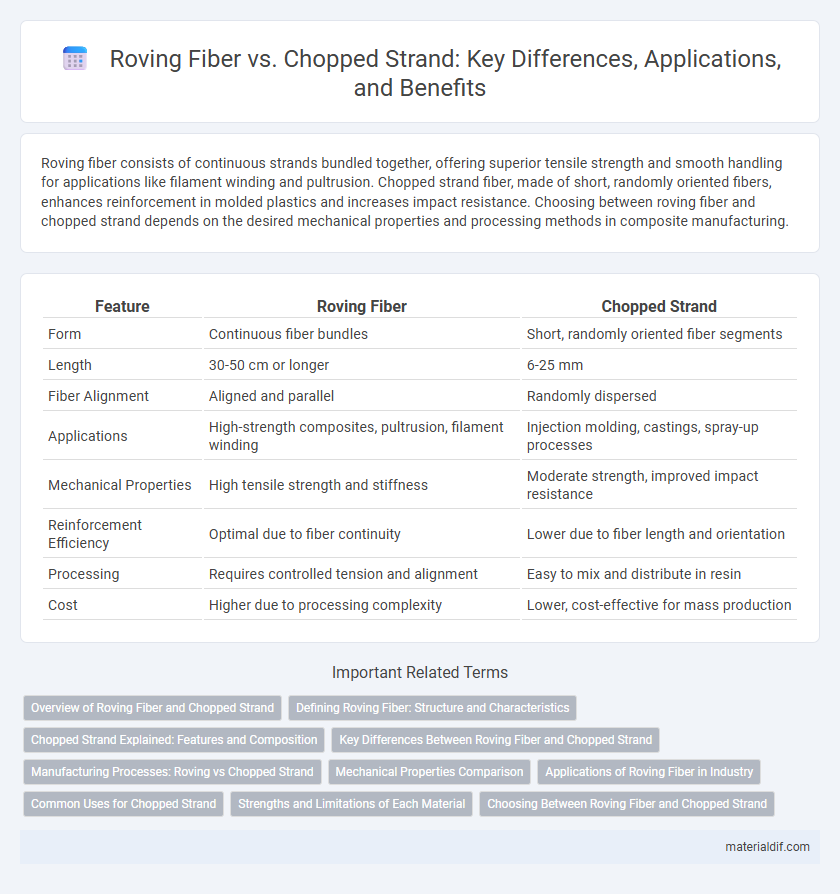

| Feature | Roving Fiber | Chopped Strand |

|---|---|---|

| Form | Continuous fiber bundles | Short, randomly oriented fiber segments |

| Length | 30-50 cm or longer | 6-25 mm |

| Fiber Alignment | Aligned and parallel | Randomly dispersed |

| Applications | High-strength composites, pultrusion, filament winding | Injection molding, castings, spray-up processes |

| Mechanical Properties | High tensile strength and stiffness | Moderate strength, improved impact resistance |

| Reinforcement Efficiency | Optimal due to fiber continuity | Lower due to fiber length and orientation |

| Processing | Requires controlled tension and alignment | Easy to mix and distribute in resin |

| Cost | Higher due to processing complexity | Lower, cost-effective for mass production |

Overview of Roving Fiber and Chopped Strand

Roving fiber consists of continuous bundles of aligned glass filaments that provide high tensile strength and flexibility, commonly used in composite reinforcement for structural applications. Chopped strand, made of short glass fibers randomly oriented and bundled into mats or chopped strand mats (CSM), offers enhanced moldability and isotropic mechanical properties ideal for automotive and marine parts. Both materials serve distinct functions in composite manufacturing, with roving fiber preferred for directional strength and chopped strand suited for complex shapes and uniform strength distribution.

Defining Roving Fiber: Structure and Characteristics

Roving fiber consists of continuous strands of fiberglass or other reinforcing materials twisted together to form a thick, rope-like structure offering superior tensile strength and flexibility. The unidirectional alignment of fibers in roving enhances load-bearing capabilities and makes it ideal for composite reinforcement in manufacturing processes. Unlike chopped strand, which is randomly oriented and shorter, roving fiber ensures consistent mechanical properties and improved impact resistance in finished products.

Chopped Strand Explained: Features and Composition

Chopped strand fiber consists of short, randomly oriented glass fibers typically ranging from 3 to 50 mm in length, enhancing composite materials with improved tensile strength and impact resistance. Its composition includes E-glass or S-glass filaments coated with a sizing agent to ensure compatibility with resin matrices such as polyester, vinyl ester, or epoxy. This fiber form offers superior molding flexibility and uniform distribution within thermoset or thermoplastic composites compared to continuous roving fibers.

Key Differences Between Roving Fiber and Chopped Strand

Roving fiber consists of long, continuous strands of glass that provide high tensile strength and superior mechanical properties, making it ideal for reinforcement in composite materials. Chopped strand is made of short, randomly distributed glass fibers that enhance isotropic properties and ease of molding in applications requiring complex shapes. The key differences lie in fiber length, orientation, and resulting structural performance, with roving fiber emphasizing strength and chopped strand focusing on versatility and ease of handling.

Manufacturing Processes: Roving vs Chopped Strand

Roving fiber manufacturing involves pulling continuous filaments from a creel to create tightly twisted bundles, providing consistent strength and alignment for composite applications. Chopped strand production cuts continuous fibers into short lengths, typically 12 to 50 mm, which are then randomly dispersed for reinforcement in molded parts. The roving process emphasizes filament uniformity and tensile integrity, while chopped strand focuses on ease of handling and improved moldability in mass production.

Mechanical Properties Comparison

Roving fiber exhibits superior tensile strength and elongation compared to chopped strand due to its continuous filament structure, providing enhanced load transfer and reduced stress concentration. Chopped strand, while easier to process and mold, typically results in lower mechanical performance with decreased impact resistance and stiffness. The choice between roving fiber and chopped strand significantly influences the final composite's structural integrity and durability in high-stress applications.

Applications of Roving Fiber in Industry

Roving fiber is extensively used in the manufacturing of composite materials, particularly in aerospace, automotive, and marine industries due to its high tensile strength and consistent filament alignment. Its continuous strands enhance the mechanical properties of fiberglass-reinforced plastics, making it ideal for producing structural components, wind turbine blades, and sports equipment. Unlike chopped strand, roving fiber's continuous form allows for superior load distribution and improved impact resistance in advanced industrial applications.

Common Uses for Chopped Strand

Chopped strand fiber is extensively used in the production of reinforced plastics, automotive parts, and construction materials due to its ability to enhance strength and durability. It is commonly incorporated into thermoset resins and composites for molding applications like boat hulls, pipes, and panels. This type of fiber is preferred for applications requiring uniform distribution and isotropic mechanical properties.

Strengths and Limitations of Each Material

Roving fiber offers high tensile strength and excellent load-bearing capacity, making it ideal for applications requiring continuous reinforcement and superior structural integrity. Chopped strand fibers provide enhanced moldability and faster production cycles but typically exhibit lower mechanical strength due to the discontinuous nature of the strands. The choice between roving fiber and chopped strand depends on balancing the need for strength versus manufacturing efficiency in composite material design.

Choosing Between Roving Fiber and Chopped Strand

Choosing between roving fiber and chopped strand depends on the desired composite properties and manufacturing process. Roving fiber offers high tensile strength and uniformity, making it suitable for structural applications requiring continuous reinforcement. Chopped strand provides better moldability and surface finish, ideal for complex shapes and lightweight components in automotive and marine industries.

Roving Fiber vs Chopped Strand Infographic

materialdif.com

materialdif.com