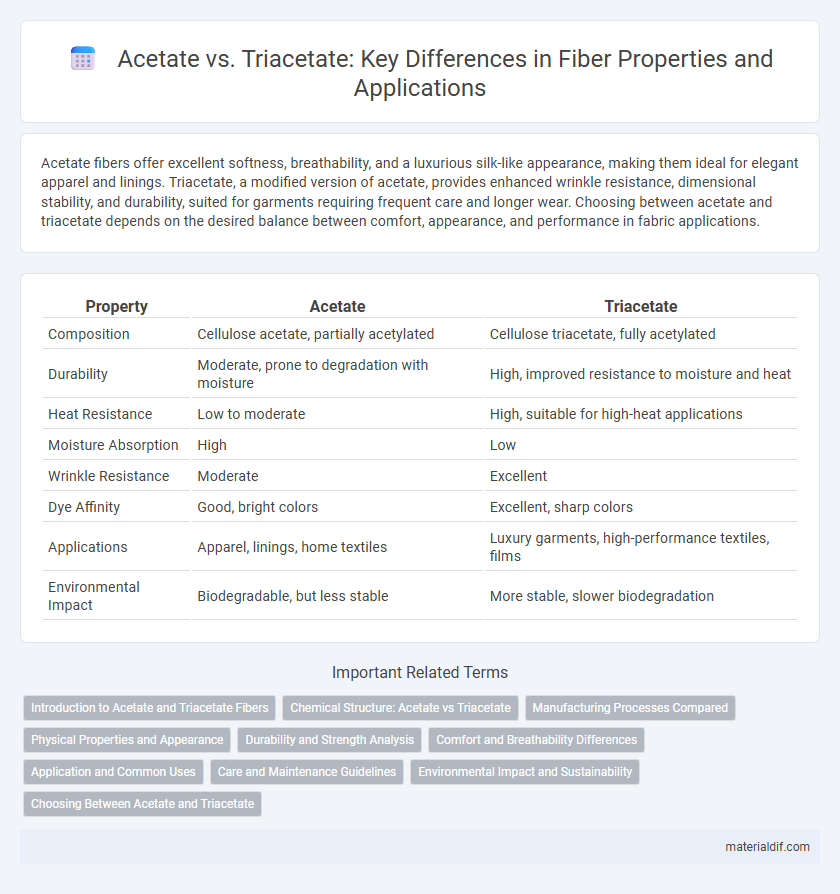

Acetate fibers offer excellent softness, breathability, and a luxurious silk-like appearance, making them ideal for elegant apparel and linings. Triacetate, a modified version of acetate, provides enhanced wrinkle resistance, dimensional stability, and durability, suited for garments requiring frequent care and longer wear. Choosing between acetate and triacetate depends on the desired balance between comfort, appearance, and performance in fabric applications.

Table of Comparison

| Property | Acetate | Triacetate |

|---|---|---|

| Composition | Cellulose acetate, partially acetylated | Cellulose triacetate, fully acetylated |

| Durability | Moderate, prone to degradation with moisture | High, improved resistance to moisture and heat |

| Heat Resistance | Low to moderate | High, suitable for high-heat applications |

| Moisture Absorption | High | Low |

| Wrinkle Resistance | Moderate | Excellent |

| Dye Affinity | Good, bright colors | Excellent, sharp colors |

| Applications | Apparel, linings, home textiles | Luxury garments, high-performance textiles, films |

| Environmental Impact | Biodegradable, but less stable | More stable, slower biodegradation |

Introduction to Acetate and Triacetate Fibers

Acetate fibers are derived from cellulose acetate, a synthetic fiber known for its silk-like appearance and soft feel, commonly used in linings and formal wear. Triacetate fibers undergo a similar process but have a higher degree of acetylation, resulting in enhanced heat resistance, dimensional stability, and wrinkle resistance compared to acetate. Both fibers belong to the group of cellulose esters and are valued for their smooth texture, vibrant dyeability, and lightweight properties.

Chemical Structure: Acetate vs Triacetate

Acetate fibers are composed of cellulose acetate with one acetyl group replacing a hydroxyl group in the cellulose chain, resulting in a partially acetylated polymer. Triacetate fibers contain cellulose triacetate, where three hydroxyl groups on the cellulose are fully acetylated, creating a more chemically stable and heat-resistant fiber. This difference in chemical structure affects properties such as durability, solubility, and resistance to environmental factors in textile applications.

Manufacturing Processes Compared

Acetate fibers are produced through a cellulose acetate spinning process involving the reaction of cellulose with acetic acid and acetic anhydride, followed by solvent-based fiber formation and extrusion. Triacetate manufacturing entails a more complex acetylation step, resulting in higher acetyl content before fiber spinning, which uses solvent spinning with enhanced heat-setting capabilities. Differences in acetylation levels affect thermal stability and fiber properties, making triacetate more resistant to heat and shrinkage during fabric production.

Physical Properties and Appearance

Acetate fibers have a smooth, silk-like appearance with a moderate luster, while triacetate fibers exhibit higher resilience and greater dimensional stability under heat. Acetate's physical properties include lower melting points and less wrinkle resistance compared to triacetate, which retains shape and resists shrinking more effectively. Both fibers share similar moisture regain but triacetate's enhanced durability makes it preferable for garments requiring frequent laundering and heat exposure.

Durability and Strength Analysis

Acetate fibers offer moderate durability with good flexibility but tend to weaken and discolor under prolonged exposure to sunlight and moisture. Triacetate fibers exhibit superior strength and enhanced resistance to heat, chemicals, and UV radiation due to their higher degree of acetylation. This enhanced durability makes triacetate preferable for applications requiring long-lasting materials with maintained structural integrity.

Comfort and Breathability Differences

Acetate fibers offer moderate breathability and a smooth, silky feel, making them comfortable for lightweight, breathable garments. Triacetate fibers enhance comfort by improving moisture-wicking properties and resisting wrinkles better than acetate, which contributes to more durable and breathable apparel. Both fibers are used in blends to balance softness and ventilation, but triacetate provides superior breathability for extended wear in warm conditions.

Application and Common Uses

Acetate fibers are commonly used in linings, lingerie, and home furnishings due to their smooth texture and ability to mimic silk, offering good drape and sheen. Triacetate fibers find applications in apparel such as skirts, dresses, and sportswear, valued for their higher wrinkle resistance, dimensional stability, and enhanced durability compared to acetate. Both fibers are favored in decorative textiles and automotive interiors, but triacetate's heat resistance makes it more suitable for garments requiring frequent laundering and pressing.

Care and Maintenance Guidelines

Acetate fibers require gentle hand washing or dry cleaning to maintain fabric integrity, avoiding high heat and prolonged exposure to sunlight to prevent shrinking and discoloration. Triacetate, known for its superior wrinkle resistance, tolerates machine washing on delicate cycles and low-temperature ironing, but should still be kept away from harsh detergents and bleach to preserve fiber strength. Both fibers benefit from air drying flat to minimize distortion and extend garment lifespan.

Environmental Impact and Sustainability

Acetate fibers, derived from cellulose, are biodegradable and have a lower environmental footprint compared to synthetic alternatives, yet their production involves toxic chemicals like acetic anhydride, impacting sustainability. Triacetate fibers, while offering superior durability and wrinkle resistance, require more energy-intensive processing and use higher levels of acetylation chemicals, which can increase environmental hazards. Choosing between acetate and triacetate hinges on balancing biodegradability against production emissions and energy consumption in sustainable textile manufacturing.

Choosing Between Acetate and Triacetate

Choosing between acetate and triacetate fibers depends on their durability and appearance requirements; acetate offers a silky finish but is less heat-resistant, making it ideal for delicate garments, while triacetate provides enhanced wrinkle resistance and better stability under heat. Triacetate fibers undergo additional chemical processing, resulting in improved dimensional stability and resistance to shrinkage, which benefits performance apparel and home textiles. Selecting the right fiber hinges on balancing aesthetic preferences with functional demands like maintenance and longevity.

Acetate vs Triacetate Infographic

materialdif.com

materialdif.com