Silk and spider silk both offer remarkable strength and elasticity, but spider silk surpasses traditional silk with superior tensile strength and durability, making it ideal for advanced applications in textiles and biomedicine. While silk is produced by silkworms and widely used in fashion, spider silk is synthesized by spiders and exhibits exceptional biocompatibility and lightweight properties. Innovations in spider silk production aim to create sustainable materials that combine the natural softness of silk with enhanced mechanical performance.

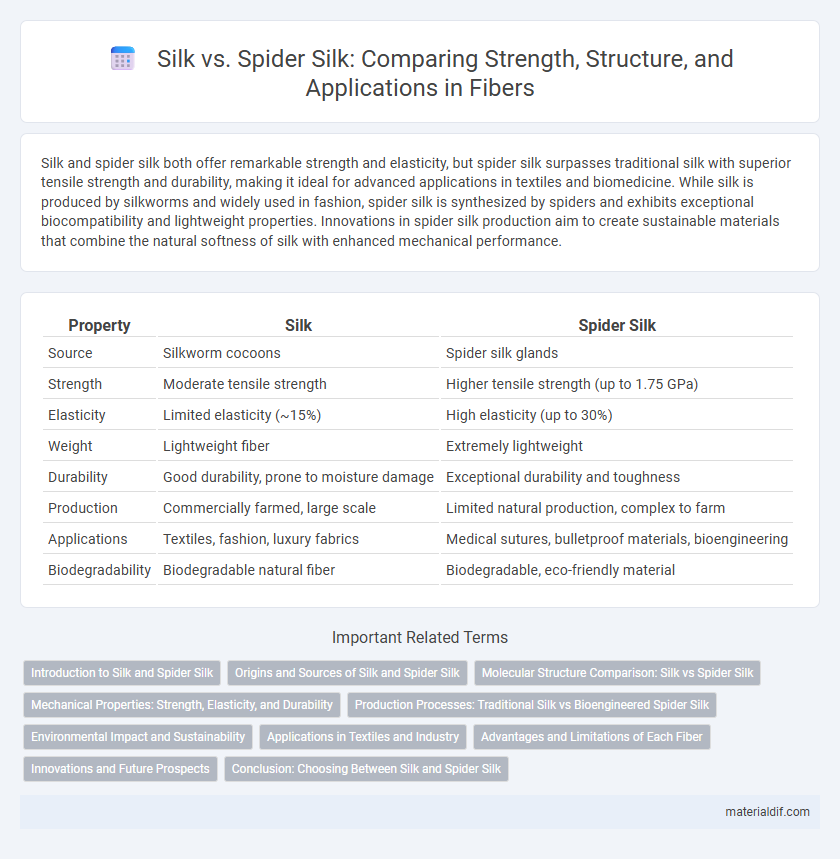

Table of Comparison

| Property | Silk | Spider Silk |

|---|---|---|

| Source | Silkworm cocoons | Spider silk glands |

| Strength | Moderate tensile strength | Higher tensile strength (up to 1.75 GPa) |

| Elasticity | Limited elasticity (~15%) | High elasticity (up to 30%) |

| Weight | Lightweight fiber | Extremely lightweight |

| Durability | Good durability, prone to moisture damage | Exceptional durability and toughness |

| Production | Commercially farmed, large scale | Limited natural production, complex to farm |

| Applications | Textiles, fashion, luxury fabrics | Medical sutures, bulletproof materials, bioengineering |

| Biodegradability | Biodegradable natural fiber | Biodegradable, eco-friendly material |

Introduction to Silk and Spider Silk

Silk, produced by silkworms, is a natural protein fiber known for its smooth texture and strong tensile strength, commonly used in textiles and luxury fabrics. Spider silk, synthesized by spiders, exhibits remarkable elasticity, toughness, and biocompatibility, making it a subject of interest for advanced materials and biomedical applications. Both fibers are composed primarily of fibroin proteins but differ in molecular structure and mechanical properties, influencing their respective industrial and scientific uses.

Origins and Sources of Silk and Spider Silk

Silk originates from the silk moth larvae, primarily the Bombyx mori species, cultivated in sericulture farms, whereas spider silk is produced by various spider species through natural spinning glands found in their abdomen. The commercial availability of silk fibers stems from controlled silk worm farming in regions like China and India, while spider silk remains rare due to the territorial and cannibalistic nature of spiders limiting large-scale harvesting. Advances in biotechnology have enabled synthetic spider silk production by replicating spider silk proteins using genetically engineered bacteria and yeast, bridging the gap between natural sources and industrial demand.

Molecular Structure Comparison: Silk vs Spider Silk

Silk, primarily composed of fibroin proteins, features a highly ordered beta-sheet crystalline structure that imparts strength and flexibility. Spider silk, unique in its molecular composition, contains a complex combination of spidroins with both crystalline beta-sheets and amorphous regions, granting exceptional toughness and elasticity. Differences in amino acid sequences and molecular alignment result in spider silk outperforming conventional silk in tensile strength and resilience.

Mechanical Properties: Strength, Elasticity, and Durability

Spider silk surpasses traditional silk in mechanical properties, exhibiting tensile strength comparable to steel and exceptional elasticity that allows it to stretch up to 40% of its length without breaking. While silk fibers from silkworms provide moderate strength and flexibility, spider silk's unique protein structure grants superior durability and resilience under stress. These attributes make spider silk a promising material for advanced applications requiring lightweight yet robust fibers.

Production Processes: Traditional Silk vs Bioengineered Spider Silk

Traditional silk production involves harvesting fibers from silkworm cocoons through sericulture, which requires large mulberry plantations and extensive labor for cocoon cultivation and harvesting. Bioengineered spider silk is produced by genetically modifying organisms such as bacteria, yeast, or plants to synthesize silk proteins, enabling scalable and controlled production without relying on spiders. This biotechnological method offers higher purity and tunability of silk properties compared to the natural variability in traditional sericulture.

Environmental Impact and Sustainability

Spider silk demonstrates superior environmental sustainability compared to traditional silk due to its renewable production methods and minimal ecological footprint. Unlike conventional silk, which requires large quantities of mulberry leaves and water resources for silkworm farming, spider silk can be bioengineered in laboratories using microbial fermentation, reducing land use and chemical inputs. This innovative approach leads to a biodegradable and high-strength fiber with significantly lower greenhouse gas emissions and resource consumption.

Applications in Textiles and Industry

Silk excels in luxury textiles due to its natural sheen, softness, and breathability, making it ideal for high-end fashion and home decor fabrics. Spider silk surpasses traditional silk in strength and elasticity, offering promising applications in industrial materials such as biodegradable medical sutures, body armor, and optical fibers. The unique molecular structure of spider silk enables its use in cutting-edge textile technologies where durability and flexibility are critical.

Advantages and Limitations of Each Fiber

Silk offers exceptional softness, luster, and excellent moisture-wicking properties, making it ideal for luxury textiles and comfort wear; however, its production is resource-intensive and less sustainable. Spider silk exhibits remarkable tensile strength, elasticity, and biodegradability, positioning it as a high-performance fiber for medical sutures and protective gear, but its commercial scalability remains limited due to complex synthetic manufacturing challenges. Both fibers present unique applications where silk excels in aesthetics and comfort, while spider silk leads in mechanical performance and sustainability potential.

Innovations and Future Prospects

Silk, traditionally sourced from silkworms, is prized for its softness and luster, while spider silk, though more challenging to harvest, offers superior tensile strength and elasticity, presenting significant innovations in material science. Recent advances in genetic engineering enable the production of spider silk proteins in scalable bioreactors, paving the way for sustainable, high-performance textiles and medical applications. Future prospects include lightweight, biodegradable composites for aerospace and advanced wound dressings, showcasing spider silk's transformative potential beyond conventional silk uses.

Conclusion: Choosing Between Silk and Spider Silk

Silk, produced by silkworms, offers consistent quality, smooth texture, and is widely available for luxurious textiles and apparel. Spider silk provides exceptional strength, elasticity, and biocompatibility, making it ideal for advanced biomedical applications and high-performance materials. Selecting between silk and spider silk depends on prioritizing either traditional textile qualities or innovative material properties for specialized uses.

Silk vs Spider silk Infographic

materialdif.com

materialdif.com