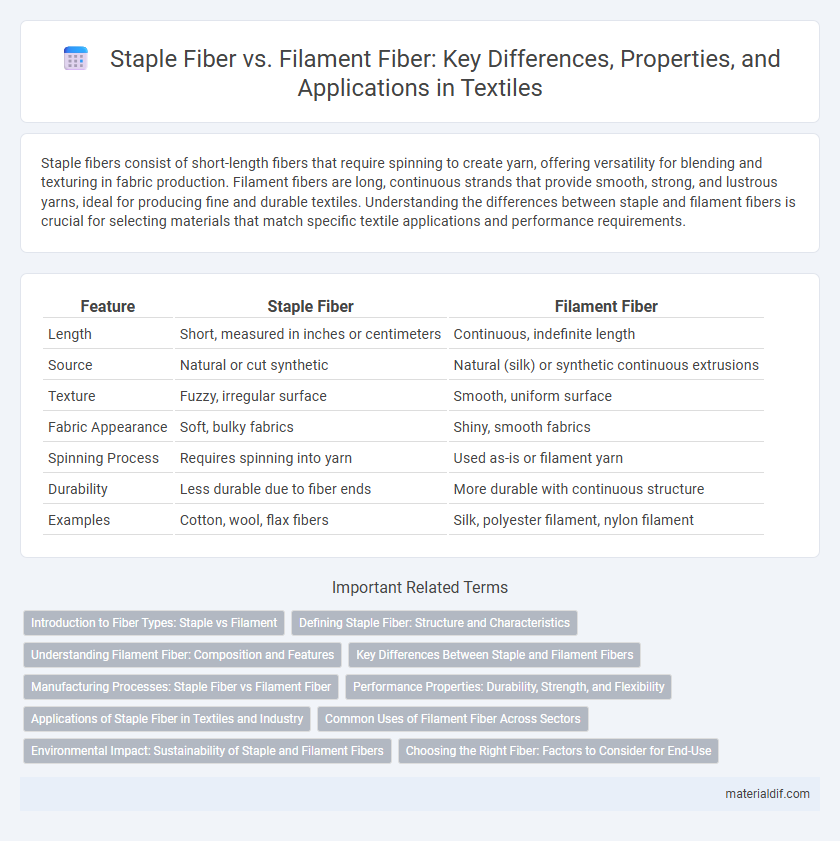

Staple fibers consist of short-length fibers that require spinning to create yarn, offering versatility for blending and texturing in fabric production. Filament fibers are long, continuous strands that provide smooth, strong, and lustrous yarns, ideal for producing fine and durable textiles. Understanding the differences between staple and filament fibers is crucial for selecting materials that match specific textile applications and performance requirements.

Table of Comparison

| Feature | Staple Fiber | Filament Fiber |

|---|---|---|

| Length | Short, measured in inches or centimeters | Continuous, indefinite length |

| Source | Natural or cut synthetic | Natural (silk) or synthetic continuous extrusions |

| Texture | Fuzzy, irregular surface | Smooth, uniform surface |

| Fabric Appearance | Soft, bulky fabrics | Shiny, smooth fabrics |

| Spinning Process | Requires spinning into yarn | Used as-is or filament yarn |

| Durability | Less durable due to fiber ends | More durable with continuous structure |

| Examples | Cotton, wool, flax fibers | Silk, polyester filament, nylon filament |

Introduction to Fiber Types: Staple vs Filament

Staple fibers consist of short lengths of fiber typically measured in inches or centimeters, commonly used in spun yarns for textiles such as cotton, wool, and synthetic fibers. Filament fibers are continuous, long strands that can extend indefinitely, found naturally in silk or manufactured as synthetic fibers like polyester and nylon. The choice between staple and filament fibers influences fabric texture, strength, and production methods in the textile industry.

Defining Staple Fiber: Structure and Characteristics

Staple fibers are short fibers with a length typically ranging from a few millimeters to several centimeters, often measured in inches, and exhibit a natural or synthetic origin. Their irregular structure, with cut ends and a rough surface, allows for easier entanglement during spinning, contributing to the tactile softness and bulk in fabrics. Common examples include cotton, wool, and flax fibers, prized for their breathability and moisture absorbency in textile applications.

Understanding Filament Fiber: Composition and Features

Filament fiber consists of continuous, long strands that can be either natural, like silk, or synthetic, such as polyester and nylon, offering smooth texture and high tensile strength. These fibers provide excellent durability, consistent diameter, and enhanced luster, making them ideal for producing fine fabrics and industrial materials. The uniformity and length of filament fibers contribute to superior fabric performance, including increased resistance to pilling and improved drape.

Key Differences Between Staple and Filament Fibers

Staple fibers are short fibers typically measured in inches or centimeters, commonly derived from natural sources like cotton or wool, while filament fibers are long, continuous fibers produced synthetically or naturally, such as silk or polyester. Staple fibers create yarns with more texture and warmth due to their irregular length and tendency to trap air, whereas filament fibers produce smoother, stronger, and more durable fabrics because of their uniform length and high tensile strength. The choice between staple and filament fibers significantly influences the fabric's appearance, feel, and performance properties in textile manufacturing.

Manufacturing Processes: Staple Fiber vs Filament Fiber

Staple fiber manufacturing involves spinning short fibers harvested from natural sources or synthetic polymers into yarn through processes such as carding, combing, and drawing. Filament fiber production creates continuous strands via extrusion techniques, where molten polymer is forced through spinnerets to form filaments that can be directly used or cut into staple fibers if needed. The distinction lies in the fiber length and production continuity, with staple fibers requiring more mechanical processing to form yarn and filament fibers offering long, uniform strands suitable for smooth, strong fabric construction.

Performance Properties: Durability, Strength, and Flexibility

Staple fibers, composed of short lengths typically under 120 mm, exhibit excellent flexibility, making them ideal for soft, breathable textiles, while filament fibers--continuous strands often exceeding 1,000 meters--provide superior strength and durability due to their unbroken construction. The durability of filament fibers outperforms staple fibers in high-stress applications such as industrial fabrics, where resistance to wear and tear is critical. Staple fibers offer enhanced elasticity and comfort, but filament fibers excel in tensile strength and long-term structural integrity, making them suitable for performance-driven uses like technical textiles and high-end apparel.

Applications of Staple Fiber in Textiles and Industry

Staple fibers, composed of short-length fibers spun into yarn, are widely used in textiles for producing soft, breathable fabrics such as cotton shirts, wool sweaters, and linen blends. In industrial applications, staple fibers reinforce composite materials, enhance insulation properties in filters, and provide cushioning in automotive upholstery. Their versatility and ease of blending with other fibers make them crucial in manufacturing durable and flexible textile products.

Common Uses of Filament Fiber Across Sectors

Filament fibers, characterized by their continuous length and smooth texture, find extensive application in textile manufacturing, especially in producing silk, nylon, and polyester fabrics known for durability and sheen. In the automotive industry, filament fibers contribute to manufacturing lightweight composite materials that enhance fuel efficiency and structural strength. Medical sectors utilize these fibers in surgical sutures and implants due to their biocompatibility and consistent tensile properties.

Environmental Impact: Sustainability of Staple and Filament Fibers

Staple fibers, typically derived from natural sources like cotton and wool, often have a lower environmental footprint due to their biodegradability and renewable origins, though intensive farming practices can impact sustainability. Filament fibers, including synthetic options like polyester and nylon, generally consume more energy and produce higher carbon emissions during production but offer durability that can extend product lifespan and reduce waste. Innovations in recycling filament fibers and developing bio-based synthetics are advancing sustainability efforts by lowering resource consumption and minimizing ecological harm.

Choosing the Right Fiber: Factors to Consider for End-Use

Staple fiber and filament fiber differ primarily in length, with staple fibers being short and filament fibers continuous, impacting the texture and strength of the final product. When choosing the right fiber, consider factors such as the desired fabric durability, softness, and the specific application, like upholstery or apparel. The end-use environment, moisture-wicking properties, and cost efficiency also play critical roles in selecting the optimal fiber type for performance and comfort.

Staple Fiber vs Filament Fiber Infographic

materialdif.com

materialdif.com