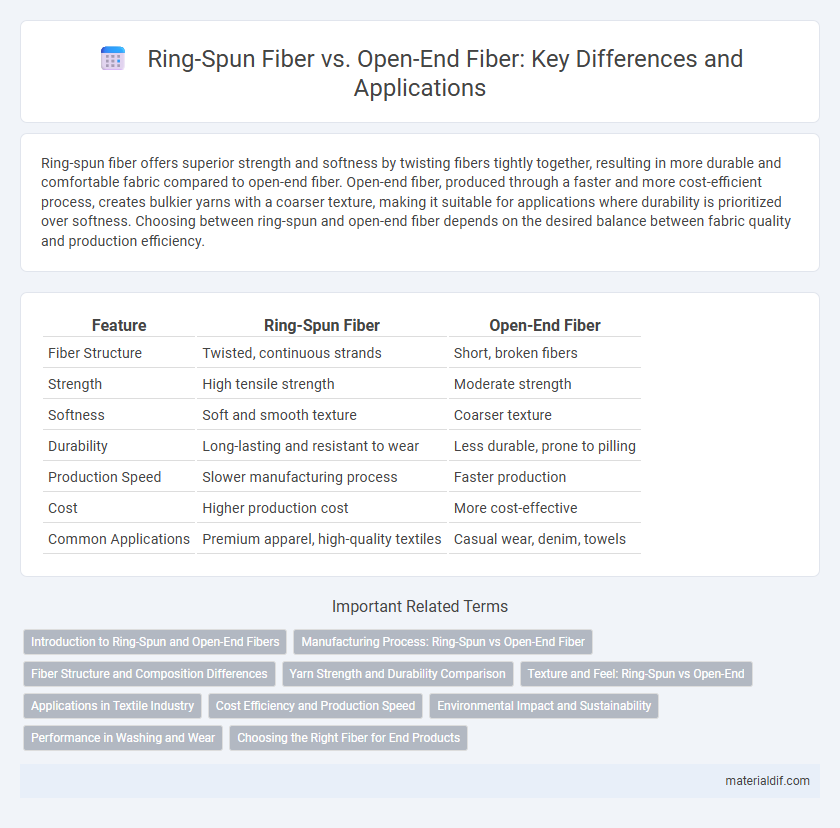

Ring-spun fiber offers superior strength and softness by twisting fibers tightly together, resulting in more durable and comfortable fabric compared to open-end fiber. Open-end fiber, produced through a faster and more cost-efficient process, creates bulkier yarns with a coarser texture, making it suitable for applications where durability is prioritized over softness. Choosing between ring-spun and open-end fiber depends on the desired balance between fabric quality and production efficiency.

Table of Comparison

| Feature | Ring-Spun Fiber | Open-End Fiber |

|---|---|---|

| Fiber Structure | Twisted, continuous strands | Short, broken fibers |

| Strength | High tensile strength | Moderate strength |

| Softness | Soft and smooth texture | Coarser texture |

| Durability | Long-lasting and resistant to wear | Less durable, prone to pilling |

| Production Speed | Slower manufacturing process | Faster production |

| Cost | Higher production cost | More cost-effective |

| Common Applications | Premium apparel, high-quality textiles | Casual wear, denim, towels |

Introduction to Ring-Spun and Open-End Fibers

Ring-spun fiber is created by continuously twisting and thinning a fiber strand, resulting in a stronger, finer, and softer yarn ideal for high-quality textiles. Open-end fiber production involves feeding fibers into a rotor, where they are spun into yarn without twisting, producing a coarser and less uniform textile ideal for mass production. These fundamental differences affect fabric texture, durability, and cost, making ring-spun optimal for premium apparel and open-end suited for bulk manufacturing.

Manufacturing Process: Ring-Spun vs Open-End Fiber

Ring-spun fiber is produced by continuously twisting and thinning the cotton strands to create a strong and fine yarn, enhancing fabric softness and durability. In contrast, open-end fiber manufacturing involves mechanically tearing fibers and spinning them without twisting, resulting in a coarser yarn with higher production speed and lower cost. The ring-spun process is more labor-intensive and slower but yields superior quality textiles compared to the faster, more economical open-end spinning method.

Fiber Structure and Composition Differences

Ring-spun fiber features tightly twisted, continuous filaments resulting in a finer, stronger yarn with a smoother surface, enhancing durability and softness in textiles. Open-end fiber is produced by mechanically twisting short staple fibers into a coarser, loftier yarn with a looser texture, which makes it less strong but more cost-effective for bulkier fabrics. The structural variation in fiber length and twist density between ring-spun and open-end fibers directly impacts fabric strength, texture, and overall garment quality.

Yarn Strength and Durability Comparison

Ring-spun fiber produces yarn with higher tensile strength and improved durability due to the continuous twisting process that aligns fibers more tightly, resulting in fewer weak points. Open-end fiber yarn, while faster and cheaper to produce, generally exhibits lower strength and durability because the fibers are less uniformly aligned and more prone to breakage under stress. The enhanced fiber cohesion in ring-spun yarn makes it the preferred choice for high-performance textile applications demanding long-lasting wear.

Texture and Feel: Ring-Spun vs Open-End

Ring-spun fiber produces a finer, softer texture due to its tightly twisted yarn, offering a smooth and luxurious feel ideal for high-quality textiles. Open-end fiber creates a coarser, thicker yarn with a rougher texture, resulting in a fabric that is more durable but less soft to the touch. The difference in spinning techniques directly impacts the comfort and tactile experience of garments made from these fibers.

Applications in Textile Industry

Ring-spun fiber produces finer, stronger yarns ideal for high-quality apparel such as premium T-shirts, dress shirts, and denim, offering superior softness and durability. Open-end fiber, characterized by faster production and coarser yarn, excels in applications like towels, upholstery, and industrial textiles where bulk and resilience are prioritized. Textile manufacturers select ring-spun fibers for luxury fabrics and open-end fibers for cost-effective, heavy-duty materials to optimize performance and production efficiency.

Cost Efficiency and Production Speed

Ring-spun fiber offers superior softness and strength but comes at a higher production cost and slower manufacturing speed compared to open-end fiber. Open-end fiber delivers greater cost efficiency and faster production rates, making it ideal for bulk textile manufacturing where speed and budget are critical factors. Manufacturers select ring-spun fiber for premium quality textiles while open-end fiber suits applications demanding rapid output and reduced expenses.

Environmental Impact and Sustainability

Ring-spun fiber production consumes more energy and water compared to open-end fiber, resulting in a higher environmental footprint. Open-end fiber manufacturing is faster and generates less waste, contributing to better sustainability outcomes. Choosing open-end fibers supports reduced resource use and lower carbon emissions in textile production.

Performance in Washing and Wear

Ring-spun fiber offers superior washing durability and wear resistance compared to open-end fiber due to its tightly twisted yarn structure, which enhances fabric strength and minimizes pilling. Open-end fiber, while more cost-effective, tends to exhibit lower abrasion resistance and higher propensity for fiber shedding during repeated washing cycles. The enhanced fiber cohesion in ring-spun yarns results in prolonged garment lifespan and better color retention after multiple washings.

Choosing the Right Fiber for End Products

Ring-spun fiber offers superior strength, softness, and durability, making it ideal for high-quality apparel and textiles requiring a smooth finish and long-lasting wear. Open-end fiber production is faster and more cost-effective, providing bulkier yarns best suited for casual clothing, denim, and towels where texture and absorbency are prioritized. Selecting the right fiber depends on balancing product requirements such as tactile comfort, durability, production speed, and budget constraints to optimize fabric performance and customer satisfaction.

Ring-Spun Fiber vs Open-End Fiber Infographic

materialdif.com

materialdif.com