Enamel glaze forms a hard, glass-like coating typically applied to metal surfaces, providing excellent durability, corrosion resistance, and vibrant color options. Ceramic glaze, on the other hand, is a silica-based coating fused onto ceramic materials during firing, creating a glossy, waterproof finish that enhances both aesthetics and functionality. While enamel glaze is ideal for metal objects, ceramic glaze is specifically designed for pottery and tile applications, each offering unique benefits tailored to their substrates.

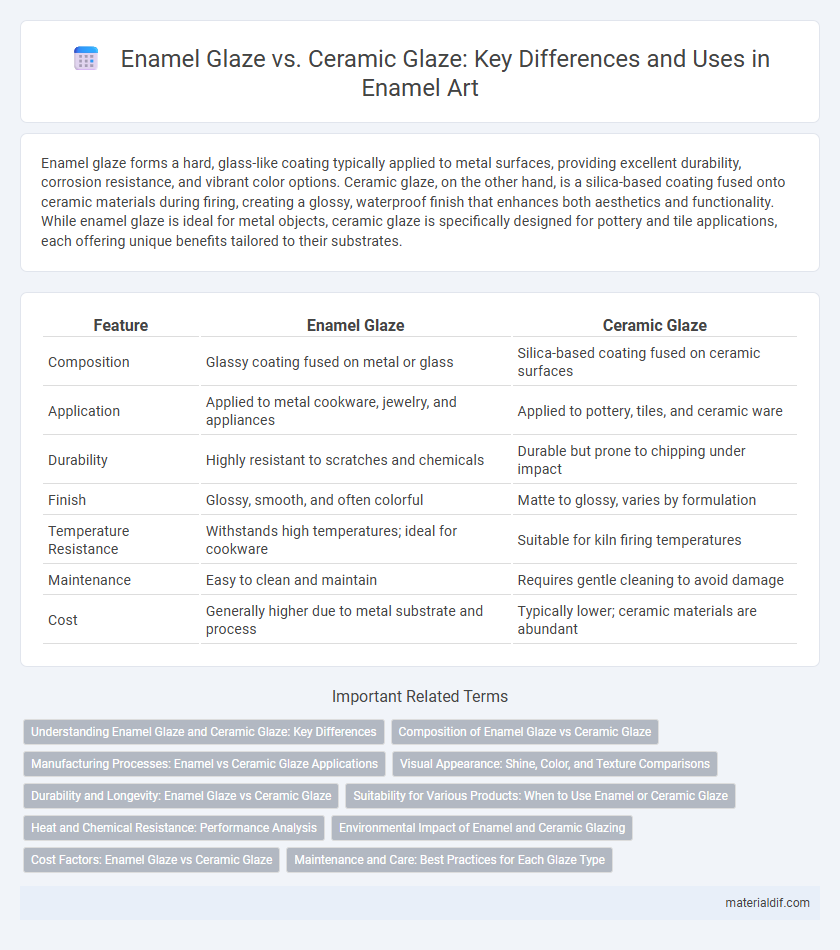

Table of Comparison

| Feature | Enamel Glaze | Ceramic Glaze |

|---|---|---|

| Composition | Glassy coating fused on metal or glass | Silica-based coating fused on ceramic surfaces |

| Application | Applied to metal cookware, jewelry, and appliances | Applied to pottery, tiles, and ceramic ware |

| Durability | Highly resistant to scratches and chemicals | Durable but prone to chipping under impact |

| Finish | Glossy, smooth, and often colorful | Matte to glossy, varies by formulation |

| Temperature Resistance | Withstands high temperatures; ideal for cookware | Suitable for kiln firing temperatures |

| Maintenance | Easy to clean and maintain | Requires gentle cleaning to avoid damage |

| Cost | Generally higher due to metal substrate and process | Typically lower; ceramic materials are abundant |

Understanding Enamel Glaze and Ceramic Glaze: Key Differences

Enamel glaze is a glassy coating fused onto metal or pottery surfaces at high temperatures, providing a durable, glossy finish resistant to heat, corrosion, and wear. Ceramic glaze, in contrast, is typically applied to pottery and porcelain, composed of silica, fluxes, and metal oxides that vitrify upon firing to create a smooth, often colorful surface enhancing both aesthetics and impermeability. The key differences lie in their material composition, substrate compatibility, and firing temperatures, with enamel glaze suited for metals and ceramic glaze primarily designed for clay-based ceramics.

Composition of Enamel Glaze vs Ceramic Glaze

Enamel glaze primarily consists of a glassy white or colored coating made from silica, fluxes, and metal oxides fused at high temperatures, resulting in a hard, durable, and glossy surface. Ceramic glaze, by contrast, contains a mixture of silica, alumina, and various fluxes that form a more porous and often matte or semi-gloss finish after firing. The key difference lies in enamel glaze's use of metal oxides that provide enhanced chemical resistance and a smoother surface compared to the more porous and variable composition of ceramic glazes.

Manufacturing Processes: Enamel vs Ceramic Glaze Applications

Enamel glaze involves fusing powdered glass onto a metal surface at high temperatures, creating a durable, glossy coating resistant to corrosion and wear. Ceramic glaze, typically applied to pottery, consists of silica, fluxes, and colorants, which vitrify during firing to form a glassy, impermeable layer enhancing both aesthetics and structural integrity. Manufacturing enamel requires controlled metallurgical preparation and firing typically between 750-850degC, while ceramic glaze processing demands precise kiln temperatures often exceeding 1000degC to achieve proper melting and bonding on clay substrates.

Visual Appearance: Shine, Color, and Texture Comparisons

Enamel glaze typically offers a high-gloss, vibrant finish with rich, saturated colors that enhance visual appeal, while ceramic glaze provides a variety of finishes ranging from matte to glossy, allowing for more diverse texture options. Enamel surfaces tend to be smoother and more reflective, creating a sleek, glass-like shine, whereas ceramic glazes can exhibit subtle textures and variations due to their firing process. Color retention in enamel is generally superior due to its chemical composition, maintaining brightness over time, while ceramic glazes may show more depth and natural variation in hues.

Durability and Longevity: Enamel Glaze vs Ceramic Glaze

Enamel glaze offers superior durability with a hard, glass-like surface that resists chipping, scratching, and corrosion, making it ideal for items exposed to heavy use and extreme conditions. Ceramic glaze, while also durable, tends to be more brittle and prone to cracking or crazing over time, especially under thermal stress. The longevity of enamel glaze outperforms ceramic glaze in environments requiring robust wear resistance and long-term preservation.

Suitability for Various Products: When to Use Enamel or Ceramic Glaze

Enamel glaze provides a durable, glossy finish ideal for metal cookware, jewelry, and decorative art due to its resistance to high temperatures and corrosion. Ceramic glaze suits pottery, tiles, and sanitaryware by offering a wide range of textures, colors, and finishes while being heat-resistant and waterproof. Choosing between enamel and ceramic glaze depends on the substrate material, desired aesthetics, and functional requirements such as heat exposure, durability, and chemical resistance.

Heat and Chemical Resistance: Performance Analysis

Enamel glaze exhibits superior heat resistance, withstanding temperatures up to 1,200degC, while ceramic glaze typically endures slightly higher thermal stress, reaching 1,300degC. Chemically, enamel glaze offers excellent resistance to acids and alkalis due to its glassy, non-porous surface, whereas ceramic glaze varies in chemical durability depending on its silica content and firing process. Performance analysis reveals that enamel glaze is preferred for corrosion-prone environments, whereas ceramic glaze is favored for high-temperature applications requiring enhanced thermal stability.

Environmental Impact of Enamel and Ceramic Glazing

Enamel glaze typically contains heavy metals such as lead and cadmium, which can pose significant environmental hazards during production and disposal, leading to soil and water contamination. Ceramic glaze, especially those formulated with natural and non-toxic minerals, tends to have a lower environmental footprint due to reduced toxic emissions and safer waste management. Sustainable ceramic glazing practices also incorporate recycling of raw materials and energy-efficient kiln technologies, minimizing overall environmental impact compared to traditional enamel processes.

Cost Factors: Enamel Glaze vs Ceramic Glaze

Enamel glaze typically incurs higher costs than ceramic glaze due to its complex application process and the use of specialized materials such as powdered glass and metal oxides for enhanced durability. Ceramic glaze is generally more cost-effective, utilizing readily available clay-based materials and simpler firing techniques, which reduces production expenses. The price difference also reflects the intended use, with enamel glazes favored for their superior resistance to chemicals and abrasion, justifying the premium in industrial applications.

Maintenance and Care: Best Practices for Each Glaze Type

Enamel glaze requires regular cleaning with non-abrasive, mild detergents to maintain its glossy surface and prevent chipping, while avoiding harsh chemicals to extend durability. Ceramic glaze benefits from periodic sealing and gentle wiping to protect against staining and maintain its natural sheen, with care focused on preventing cracks by avoiding sudden temperature changes. Both glaze types necessitate attentive maintenance tailored to their material properties to ensure longevity and aesthetic quality.

Enamel Glaze vs Ceramic Glaze Infographic

materialdif.com

materialdif.com