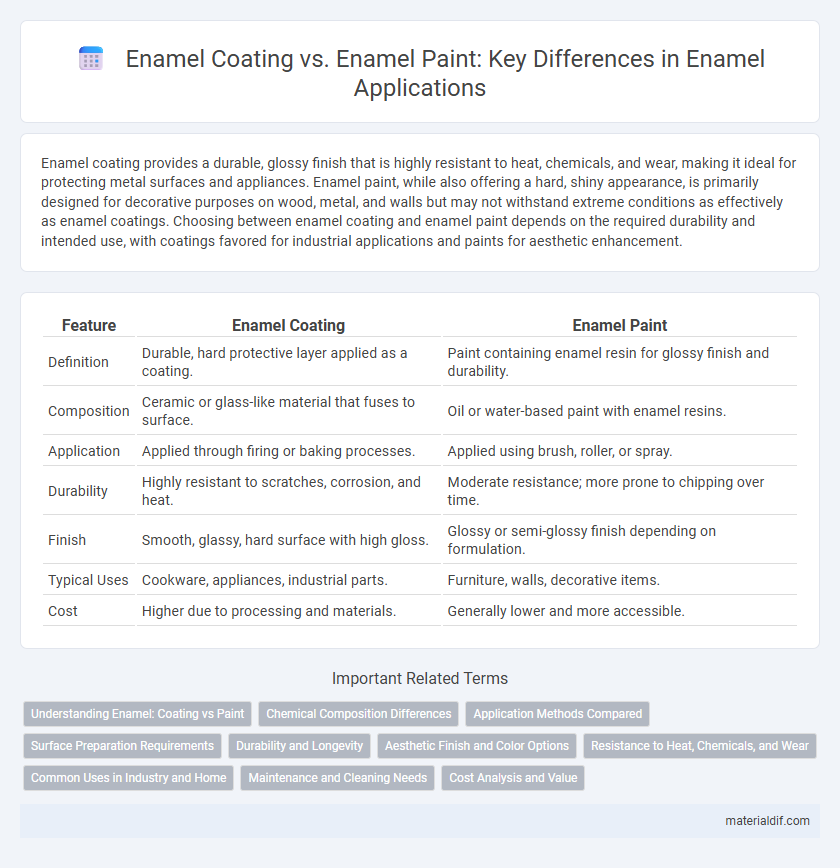

Enamel coating provides a durable, glossy finish that is highly resistant to heat, chemicals, and wear, making it ideal for protecting metal surfaces and appliances. Enamel paint, while also offering a hard, shiny appearance, is primarily designed for decorative purposes on wood, metal, and walls but may not withstand extreme conditions as effectively as enamel coatings. Choosing between enamel coating and enamel paint depends on the required durability and intended use, with coatings favored for industrial applications and paints for aesthetic enhancement.

Table of Comparison

| Feature | Enamel Coating | Enamel Paint |

|---|---|---|

| Definition | Durable, hard protective layer applied as a coating. | Paint containing enamel resin for glossy finish and durability. |

| Composition | Ceramic or glass-like material that fuses to surface. | Oil or water-based paint with enamel resins. |

| Application | Applied through firing or baking processes. | Applied using brush, roller, or spray. |

| Durability | Highly resistant to scratches, corrosion, and heat. | Moderate resistance; more prone to chipping over time. |

| Finish | Smooth, glassy, hard surface with high gloss. | Glossy or semi-glossy finish depending on formulation. |

| Typical Uses | Cookware, appliances, industrial parts. | Furniture, walls, decorative items. |

| Cost | Higher due to processing and materials. | Generally lower and more accessible. |

Understanding Enamel: Coating vs Paint

Enamel coating refers to a durable, glass-like layer often applied through heat curing, providing superior protection against corrosion and wear on surfaces like metal and ceramics. Enamel paint, by contrast, is a solvent-based or water-based paint that dries to a hard, glossy finish but lacks the same level of chemical and thermal resistance found in enamel coatings. Understanding the differences between enamel coating and enamel paint is crucial for selecting the appropriate finish for applications requiring longevity, resistance, and aesthetic appeal.

Chemical Composition Differences

Enamel coating typically consists of a durable, hard chemical formulation with alkyd or epoxy bases, providing enhanced resistance to abrasion and chemicals. Enamel paint generally contains pigments suspended in a solvent with oil or synthetic resins, resulting in a glossy finish but less robust structural integrity. The key chemical difference lies in the enamel coating's cross-linking polymers, which create a tough, protective layer, whereas enamel paint emphasizes aesthetics with less emphasis on protective qualities.

Application Methods Compared

Enamel coating typically requires specialized spray or dip application for uniform thickness and durability, making it ideal for industrial and protective finishes. Enamel paint is commonly applied using brushes or rollers, offering ease for DIY projects and decorative surfaces. The choice between methods impacts drying time, finish quality, and adhesion strength, with coatings generally offering a harder, more resistant surface than paint.

Surface Preparation Requirements

Enamel coating requires meticulous surface preparation, including thorough cleaning, degreasing, and often the application of a primer to ensure strong adhesion and durability. Enamel paint, while also benefiting from clean and smooth surfaces, generally tolerates less rigorous preparation and can be applied directly to properly cleaned and lightly sanded surfaces. Proper surface preparation directly impacts the longevity and finish quality of both enamel coatings and enamel paints.

Durability and Longevity

Enamel coating offers superior durability due to its hard, glass-like finish that resists chipping, scratching, and corrosion, making it ideal for surfaces exposed to heavy wear and weather conditions. Enamel paint provides a durable finish but is generally softer and less resistant to abrasion and fading over time compared to enamel coatings. Longevity is enhanced in enamel coatings through their chemical composition, which forms a tougher, more resistant layer than the pigmented film produced by enamel paint.

Aesthetic Finish and Color Options

Enamel coating provides a durable, glossy finish that enhances surfaces with long-lasting protection and a smooth texture ideal for high-traffic areas. Enamel paint offers a broader spectrum of vibrant color options, allowing for creative customization with a high-gloss or satin sheen that brightens any space. Both enamel coating and paint deliver aesthetic appeal, but enamel paint excels in versatility and color variety while enamel coating prioritizes robust surface protection.

Resistance to Heat, Chemicals, and Wear

Enamel coating provides superior resistance to heat, chemicals, and wear compared to enamel paint due to its dense, glass-like finish that forms a hard, protective layer on surfaces. This coating is typically baked at high temperatures, enhancing durability and making it ideal for industrial and cookware applications exposed to extreme conditions. Enamel paint, while offering good aesthetic appeal and some protection, lacks the same level of heat resistance and chemical durability, making it more suitable for decorative purposes rather than heavy-duty use.

Common Uses in Industry and Home

Enamel coating is widely used in industrial applications for its durability and resistance to heat, chemicals, and abrasion, making it ideal for machinery, automotive parts, and appliances. Enamel paint, favored in home settings, provides a glossy, hard finish suitable for furniture, walls, and metal surfaces, enhancing aesthetic appeal while offering moderate protection. Both types serve protective and decorative functions but differ in formulation and typical usage environments.

Maintenance and Cleaning Needs

Enamel coating offers superior durability and resistance to scratches, making it easier to clean and maintain over time compared to enamel paint. Enamel paint, while providing a smooth and glossy finish, may require more frequent touch-ups and careful cleaning to prevent chipping or fading. Proper maintenance of enamel coating typically involves simple wiping with mild detergent, whereas enamel paint surfaces might need specialized cleaners to preserve their appearance.

Cost Analysis and Value

Enamel coating typically offers a higher initial cost compared to enamel paint due to its durability and resistance to wear, which reduces long-term maintenance expenses. Enamel paint, while more affordable upfront, may require frequent touch-ups or reapplication, increasing overall lifecycle costs. Evaluating the value of both options depends on the intended application, with enamel coating favored for industrial or high-traffic environments where longevity justifies the investment.

Enamel coating vs enamel paint Infographic

materialdif.com

materialdif.com