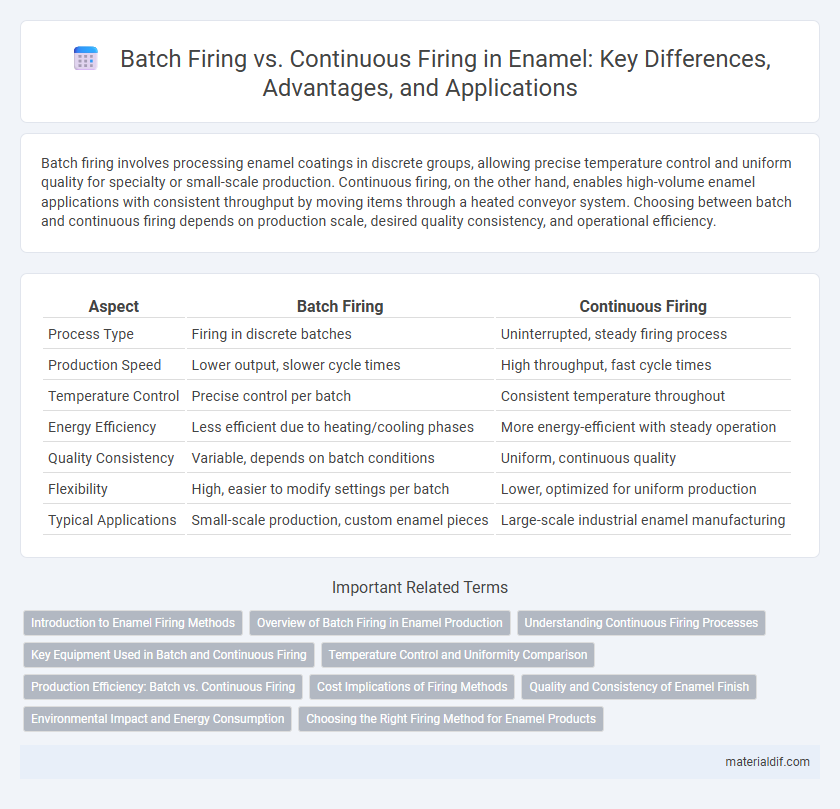

Batch firing involves processing enamel coatings in discrete groups, allowing precise temperature control and uniform quality for specialty or small-scale production. Continuous firing, on the other hand, enables high-volume enamel applications with consistent throughput by moving items through a heated conveyor system. Choosing between batch and continuous firing depends on production scale, desired quality consistency, and operational efficiency.

Table of Comparison

| Aspect | Batch Firing | Continuous Firing |

|---|---|---|

| Process Type | Firing in discrete batches | Uninterrupted, steady firing process |

| Production Speed | Lower output, slower cycle times | High throughput, fast cycle times |

| Temperature Control | Precise control per batch | Consistent temperature throughout |

| Energy Efficiency | Less efficient due to heating/cooling phases | More energy-efficient with steady operation |

| Quality Consistency | Variable, depends on batch conditions | Uniform, continuous quality |

| Flexibility | High, easier to modify settings per batch | Lower, optimized for uniform production |

| Typical Applications | Small-scale production, custom enamel pieces | Large-scale industrial enamel manufacturing |

Introduction to Enamel Firing Methods

Enamel firing methods primarily include batch firing and continuous firing, each affecting the enamel coating's quality and durability. Batch firing involves heating enamel-coated items in a kiln for a set period, allowing precise control over temperature and firing cycles, ideal for small-scale or custom pieces. Continuous firing uses a conveyor belt system to pass items through a furnace rapidly, enabling high-volume production with consistent enamel adhesion and surface finish.

Overview of Batch Firing in Enamel Production

Batch firing in enamel production involves processing enamel-coated substrates in discrete groups within a kiln, allowing precise control over temperature and firing time to achieve consistent coating quality. This method is ideal for small to medium production runs where flexibility and customization are necessary, enabling adjustments for different enamel formulations and substrate types. Temperature typically ranges between 750degC and 900degC, ensuring proper fusion of enamel particles for durable, smooth finishes.

Understanding Continuous Firing Processes

Continuous firing processes in enamel production involve the uninterrupted movement of coated substrates through a high-temperature furnace, enabling consistent and uniform enamel application. This method enhances production efficiency by reducing cycle times and minimizing thermal stress on materials compared to batch firing, which processes enamel in discrete batches. Continuous firing is particularly advantageous for large-scale manufacturing where consistent quality and throughput are critical.

Key Equipment Used in Batch and Continuous Firing

Batch firing in enamel processes primarily utilizes batch kilns such as electric or gas-fired muffle kilns, allowing precise control over temperature and atmosphere for small to medium production runs. Continuous firing relies on conveyor belt kilns or tunnel kilns, which facilitate uninterrupted processing with consistent temperature profiles, ideal for large-scale, high-volume production. Key equipment choice impacts energy consumption, throughput efficiency, and enamel coating quality in both firing methods.

Temperature Control and Uniformity Comparison

Batch firing offers precise temperature control by allowing consistent heating cycles tailored for each enamel batch, resulting in uniform enamel coating thickness. Continuous firing uses a conveyor system with a steady temperature profile, promoting high throughput but potentially causing slight temperature fluctuations that may affect uniformity. For applications demanding tight enamel consistency, batch firing typically provides superior temperature stability compared to continuous firing.

Production Efficiency: Batch vs. Continuous Firing

Batch firing offers flexibility in producing varied enamel products but often results in longer cycle times and increased downtime between batches. Continuous firing enhances production efficiency by maintaining steady furnace temperatures and reducing labor costs through automation. This method is ideal for large-scale enamel manufacturing, providing consistent quality and faster throughput compared to batch processing.

Cost Implications of Firing Methods

Batch firing involves firing groups of items simultaneously in a kiln, allowing for energy savings on small production runs but higher labor costs per unit. Continuous firing, using conveyor systems, offers greater efficiency and lower labor expenses for large-scale production while consuming more consistent energy, resulting in higher upfront equipment investment. Choosing between batch and continuous firing methods depends on balancing kiln fuel costs, labor, throughput requirements, and capital expenditure constraints.

Quality and Consistency of Enamel Finish

Batch firing provides superior control over temperature and atmosphere, resulting in a more uniform and high-quality enamel finish with fewer defects. Continuous firing offers higher production efficiency but may sacrifice some consistency due to variable heat exposure and shorter process times. For applications demanding precise enamel properties and flawless surface finishes, batch firing remains the preferred method.

Environmental Impact and Energy Consumption

Batch firing in enamel production consumes more energy per cycle due to repeated heating and cooling phases, resulting in higher greenhouse gas emissions and greater environmental impact. Continuous firing processes maintain consistent kiln temperatures, improving energy efficiency and reducing carbon footprint by minimizing thermal loss. Optimizing enamel firing methods by favoring continuous firing supports sustainable manufacturing through lower fuel consumption and decreased pollutant release.

Choosing the Right Firing Method for Enamel Products

Batch firing offers precise temperature control essential for delicate enamel designs, ensuring consistent quality in small to medium production runs. Continuous firing suits large-scale manufacturing, providing faster processing times and uniform enamel coating through automated conveyor systems. Selecting the right firing method depends on production volume, enamel complexity, and the desired finish durability.

Batch firing vs Continuous firing Infographic

materialdif.com

materialdif.com