Lead-free enamel offers a safer alternative to leaded enamel by eliminating the health risks associated with lead exposure, such as toxicity and environmental contamination. It provides comparable durability, gloss, and color retention, making it ideal for household items and cookware. Choosing lead-free enamel ensures compliance with health regulations while maintaining high-quality finishes.

Table of Comparison

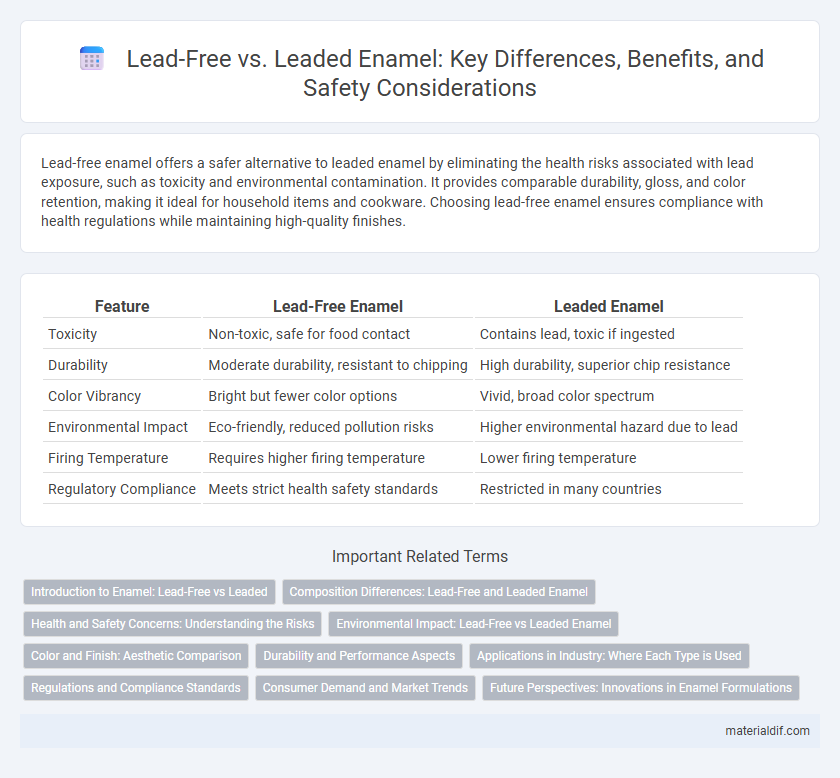

| Feature | Lead-Free Enamel | Leaded Enamel |

|---|---|---|

| Toxicity | Non-toxic, safe for food contact | Contains lead, toxic if ingested |

| Durability | Moderate durability, resistant to chipping | High durability, superior chip resistance |

| Color Vibrancy | Bright but fewer color options | Vivid, broad color spectrum |

| Environmental Impact | Eco-friendly, reduced pollution risks | Higher environmental hazard due to lead |

| Firing Temperature | Requires higher firing temperature | Lower firing temperature |

| Regulatory Compliance | Meets strict health safety standards | Restricted in many countries |

Introduction to Enamel: Lead-Free vs Leaded

Lead-free enamel is formulated without toxic lead, offering a safer alternative for consumers and artisans, particularly in food and beverage containers where safety regulations are stringent. Leaded enamel, historically used for its durability and vibrant finish, poses health risks due to lead leaching, prompting its decline in many industries. The shift toward lead-free enamel aligns with environmental standards and public health priorities, ensuring non-toxic and sustainable enamel coatings.

Composition Differences: Lead-Free and Leaded Enamel

Lead-free enamel contains alternative fluxing agents such as boron and zinc oxides, replacing lead oxide to reduce toxicity while maintaining durability and gloss. Leaded enamel primarily consists of lead oxide combined with silica and other minerals, providing superior adhesion, flexibility, and glassy finish. The absence of lead in lead-free enamel improves environmental safety and compliance with health regulations without significantly compromising performance.

Health and Safety Concerns: Understanding the Risks

Lead-free enamel eliminates the health hazards associated with lead exposure, such as neurological damage and respiratory issues, making it a safer choice for cookware and decorative items. Leaded enamel, while traditionally valued for its durability and vibrant colors, poses significant risks due to lead leaching, especially when exposed to acidic foods or high temperatures. Selecting lead-free enamel products reduces the risk of lead poisoning and supports safer indoor air quality and consumer health.

Environmental Impact: Lead-Free vs Leaded Enamel

Lead-free enamel significantly reduces environmental contamination by eliminating toxic lead emissions during production and disposal, promoting safer waste management. Leaded enamel contributes to soil and water pollution due to lead leaching, posing long-term ecological and health hazards. Regulatory trends favor lead-free formulations to minimize environmental impact and support sustainable manufacturing practices.

Color and Finish: Aesthetic Comparison

Lead-free enamel offers a vibrant, consistent color palette with a smooth, glossy finish that resists yellowing and dullness over time, enhancing the visual appeal of ceramic and metal surfaces. In contrast, leaded enamel typically provides richer, deeper hues with a glass-like sheen but may lose its brightness and develop fine cracks, impacting long-term aesthetics. Both types deliver high-quality finishes, but lead-free enamel prioritizes safety and durability without compromising on color vibrancy or surface smoothness.

Durability and Performance Aspects

Lead-free enamel offers enhanced durability and superior resistance to chipping and cracking compared to leaded enamel, making it ideal for long-term applications. Leaded enamel, while traditionally valued for its smooth finish and vibrant color retention, tends to be less robust under thermal stress and mechanical impact. The non-toxic nature of lead-free enamel also contributes to safer performance in household and industrial products without compromising structural integrity.

Applications in Industry: Where Each Type is Used

Lead-free enamel is widely used in food and beverage containers, cookware, and medical equipment due to its non-toxic properties and compliance with health and safety regulations. Leaded enamel, known for its superior durability and vibrant finish, is commonly applied in industrial components, automotive parts, and high-temperature machinery where chemical resistance and longevity are critical. The choice between lead-free and leaded enamel depends heavily on application requirements, regulatory standards, and environmental considerations.

Regulations and Compliance Standards

Lead-free enamel complies with stringent global regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the United States Environmental Protection Agency (EPA) standards, ensuring safer consumer products and reduced environmental impact. Leaded enamel faces increasing restrictions and bans in many countries due to its toxicity and health risks, including lead poisoning and environmental contamination. Manufacturers prioritize lead-free enamel formulations to meet certifications like NSF/ANSI 61 for drinking water safety and to maintain compliance with stringent health and environmental legislation.

Consumer Demand and Market Trends

Consumer demand for lead-free enamel has surged due to growing health and environmental concerns, driving manufacturers to innovate safer, non-toxic coatings. Market trends indicate a steady decline in leaded enamel usage, as regulatory restrictions tighten globally and eco-friendly products gain preference among eco-conscious buyers. This shift has spurred increased investment in lead-free enamel technologies, expanding their market share across industries like cookware, automotive, and construction.

Future Perspectives: Innovations in Enamel Formulations

Future perspectives in enamel formulations emphasize the development of lead-free enamel alternatives that maintain durability and aesthetic appeal while eliminating toxic lead content. Innovations include advanced nanoparticle additives and eco-friendly fluxes that enhance scratch resistance, color vibrancy, and thermal stability without compromising environmental safety. Research is increasingly directed toward bio-based and recyclable enamel coatings, aligning with global regulatory trends and consumer demand for sustainable materials.

Lead-Free Enamel vs Leaded Enamel Infographic

materialdif.com

materialdif.com