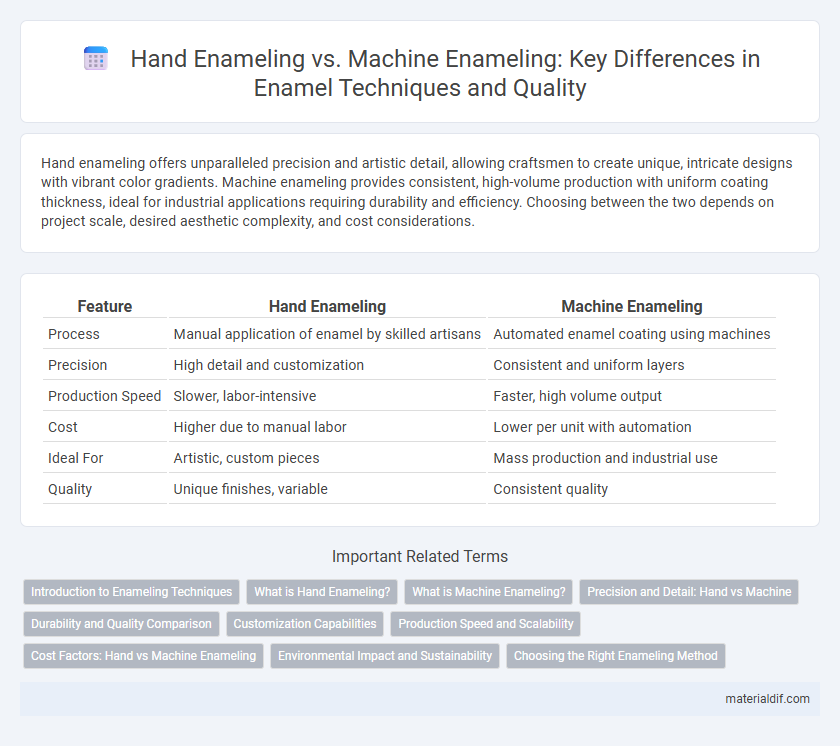

Hand enameling offers unparalleled precision and artistic detail, allowing craftsmen to create unique, intricate designs with vibrant color gradients. Machine enameling provides consistent, high-volume production with uniform coating thickness, ideal for industrial applications requiring durability and efficiency. Choosing between the two depends on project scale, desired aesthetic complexity, and cost considerations.

Table of Comparison

| Feature | Hand Enameling | Machine Enameling |

|---|---|---|

| Process | Manual application of enamel by skilled artisans | Automated enamel coating using machines |

| Precision | High detail and customization | Consistent and uniform layers |

| Production Speed | Slower, labor-intensive | Faster, high volume output |

| Cost | Higher due to manual labor | Lower per unit with automation |

| Ideal For | Artistic, custom pieces | Mass production and industrial use |

| Quality | Unique finishes, variable | Consistent quality |

Introduction to Enameling Techniques

Hand enameling involves applying powdered glass onto metal surfaces using traditional methods such as sifting and brushwork, offering precise control and artistry in design. Machine enameling employs automated processes like electrostatic spraying or firing in continuous kilns, enhancing speed and uniformity for large-scale production. These techniques differ significantly in craftsmanship, production capacity, and finish quality, catering to distinct artistic and industrial needs.

What is Hand Enameling?

Hand enameling is a traditional technique where powdered glass is meticulously applied onto a metal surface by skilled artisans before firing in a kiln to fuse the enamel. This process allows for intricate designs, color layering, and fine detail that machines cannot replicate with the same level of artistry and customization. Hand enameling ensures unique, high-quality finishes often valued in jewelry, watchmaking, and decorative arts for its precision and craftsmanship.

What is Machine Enameling?

Machine enameling is a manufacturing process that applies powdered glass coatings onto metal surfaces using automated equipment, ensuring consistent thickness and even coverage. Unlike hand enameling, which relies on skilled artisans to manually apply and fuse enamel layers, machine enameling employs high-speed conveyor systems and controlled firing cycles for mass production. This method enhances durability, uniformity, and efficiency in creating enamel-coated products across various industries, including automotive and cookware.

Precision and Detail: Hand vs Machine

Hand enameling offers unparalleled precision and intricate detail due to the artisan's direct control over brush strokes and layering, allowing for unique textures and subtle color variations. Machine enameling provides consistent, uniform coatings ideal for large-scale production but often lacks the nuanced artistry found in hand-applied pieces. Precision in hand enameling results in custom finishes with exceptional depth, whereas machine processes prioritize efficiency and repeatability over fine detail.

Durability and Quality Comparison

Hand enameling offers superior durability due to the artisan's precise control over layering and firing, resulting in a unique, high-quality finish with rich texture and color depth. Machine enameling, while faster and more consistent for large-scale production, may sacrifice some durability and intricate detail, often producing a smoother but less vibrant coating. The choice between hand and machine enameling significantly impacts the longevity and aesthetic quality of the enamel surface.

Customization Capabilities

Hand enameling offers superior customization capabilities, allowing artisans to create intricate designs with precise control over color gradients and layering techniques. Machine enameling provides consistency and efficiency but often lacks the nuanced detail achievable through manual methods. Custom pieces demanding unique artistry and variable textures benefit significantly from hand enameling's flexibility.

Production Speed and Scalability

Hand enameling offers precise artistic control but has significantly slower production speed compared to machine enameling, which can process large volumes rapidly. Machine enameling ensures consistent quality and scalability, making it ideal for mass production of enamel-coated products. The choice between methods depends on balancing handcrafted detail with the need for high throughput and scalability in manufacturing.

Cost Factors: Hand vs Machine Enameling

Hand enameling incurs higher labor costs due to skilled craftsmanship and longer production times, making it more expensive than machine enameling. Machine enameling reduces material waste and increases throughput, significantly lowering overall manufacturing expenses. Investment in automated equipment raises initial costs but leads to consistent quality and cost efficiency in large-scale enamel production.

Environmental Impact and Sustainability

Hand enameling uses artisanal techniques with minimal waste and lower energy consumption, making it more environmentally sustainable than machine enameling, which relies on high-energy industrial ovens and generates greater emissions. The handcrafted process allows precise control over materials, reducing harmful chemical runoff and supporting eco-conscious production. Sustainable practices in hand enameling contribute to lower carbon footprints and promote long-term environmental responsibility compared to mass-produced, machine-enamelled goods.

Choosing the Right Enameling Method

Hand enameling offers unparalleled precision and artistic control, ideal for intricate designs and custom, small-batch projects. Machine enameling provides high efficiency and uniform coating, suitable for large-scale production with consistent quality. Selecting the right enameling method depends on factors such as design complexity, production volume, and budget constraints.

Hand Enameling vs Machine Enameling Infographic

materialdif.com

materialdif.com