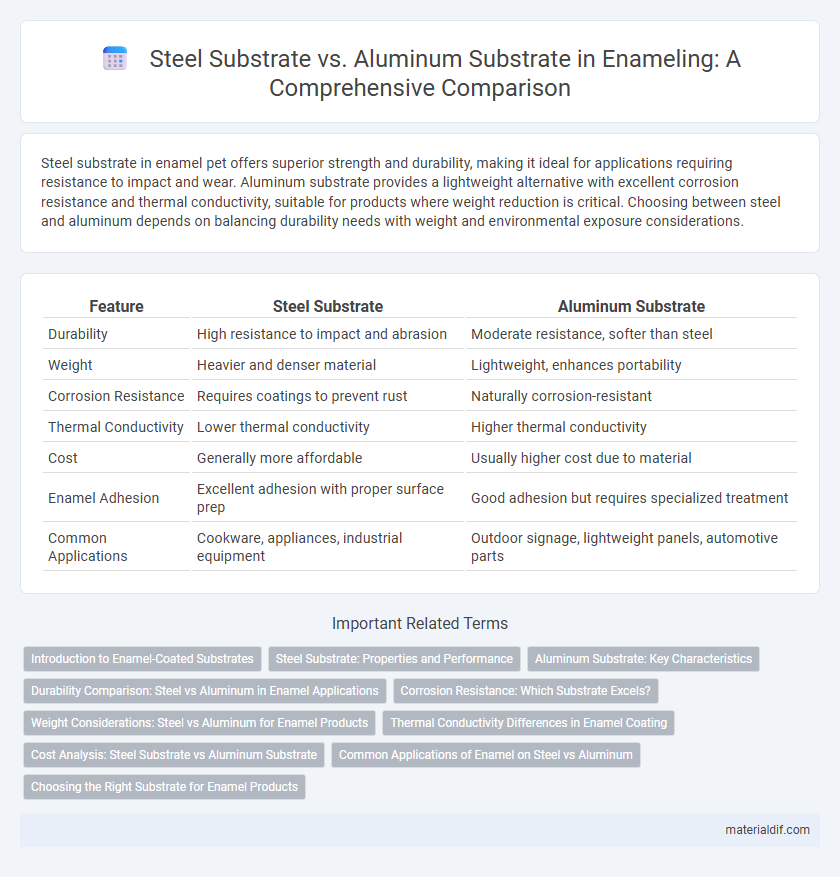

Steel substrate in enamel pet offers superior strength and durability, making it ideal for applications requiring resistance to impact and wear. Aluminum substrate provides a lightweight alternative with excellent corrosion resistance and thermal conductivity, suitable for products where weight reduction is critical. Choosing between steel and aluminum depends on balancing durability needs with weight and environmental exposure considerations.

Table of Comparison

| Feature | Steel Substrate | Aluminum Substrate |

|---|---|---|

| Durability | High resistance to impact and abrasion | Moderate resistance, softer than steel |

| Weight | Heavier and denser material | Lightweight, enhances portability |

| Corrosion Resistance | Requires coatings to prevent rust | Naturally corrosion-resistant |

| Thermal Conductivity | Lower thermal conductivity | Higher thermal conductivity |

| Cost | Generally more affordable | Usually higher cost due to material |

| Enamel Adhesion | Excellent adhesion with proper surface prep | Good adhesion but requires specialized treatment |

| Common Applications | Cookware, appliances, industrial equipment | Outdoor signage, lightweight panels, automotive parts |

Introduction to Enamel-Coated Substrates

Enamel-coated substrates commonly include steel and aluminum, each offering distinct benefits in durability and corrosion resistance. Steel substrates provide high strength and excellent adherence for enamel coatings, making them ideal for appliances and cookware. Aluminum substrates offer lightweight properties and enhanced heat conduction, which improve enamel performance in automotive and architectural applications.

Steel Substrate: Properties and Performance

Steel substrates offer exceptional strength and durability, making them ideal for enamel coatings requiring high impact resistance and structural support. Their superior thermal conductivity ensures uniform heat distribution during enameling, resulting in a consistently smooth, chip-resistant finish. Steel's resistance to corrosion and mechanical wear enhances the longevity and performance of enamel products in industrial and household applications.

Aluminum Substrate: Key Characteristics

Aluminum substrates offer excellent corrosion resistance and lightweight properties, making them ideal for enamel coatings in marine and architectural applications. Their high thermal conductivity enhances enamel curing processes, ensuring uniform coating adherence and durability. Additionally, aluminum's natural oxide layer provides superior bonding strength, improving enamel longevity compared to steel substrates.

Durability Comparison: Steel vs Aluminum in Enamel Applications

Steel substrates offer superior durability in enamel applications due to their higher tensile strength and resistance to impact, making them ideal for heavy-duty use. Aluminum substrates provide excellent corrosion resistance and lightweight properties but may suffer from lower abrasion resistance compared to steel when coated with enamel. The choice between steel and aluminum substrates in enamel applications depends on specific performance requirements such as strength, weight, and environmental exposure.

Corrosion Resistance: Which Substrate Excels?

Steel substrates coated with enamel generally offer superior corrosion resistance compared to aluminum substrates due to the steel's inherent strength and the enamel's strong adhesion properties, which create a robust barrier against moisture and chemical exposure. Aluminum substrates, while lightweight and naturally resistant to oxidation, often require specialized enamel formulations to achieve comparable corrosion protection, making them less effective in highly aggressive environments. The choice between steel and aluminum enamel substrates depends on specific application demands, with steel preferred for heavy-duty, corrosive conditions and aluminum for lightweight, moderate-corrosion scenarios.

Weight Considerations: Steel vs Aluminum for Enamel Products

Aluminum substrates offer a significant weight advantage over steel, making them ideal for enamel products where reducing overall mass is crucial. Steel substrates provide greater strength and durability but contribute to a heavier finished product, impacting transportation and handling costs. Weight considerations often drive the choice of substrate in enamel applications, balancing performance requirements with cost-efficiency.

Thermal Conductivity Differences in Enamel Coating

Steel substrates exhibit lower thermal conductivity compared to aluminum substrates, impacting the heat distribution in enamel coatings. Enamel applied to aluminum substrates benefits from aluminum's high thermal conductivity, facilitating quicker cooling and reducing thermal stress during the coating process. This property difference influences enamel adhesion, durability, and overall performance in applications requiring efficient heat dissipation.

Cost Analysis: Steel Substrate vs Aluminum Substrate

Steel substrates generally offer a lower initial material cost compared to aluminum substrates, making them a cost-effective choice for enamel applications. The durability and higher strength of steel can reduce long-term maintenance expenses, while aluminum substrates typically incur higher fabrication and handling costs due to their softness and susceptibility to deformation. Overall, the total cost analysis favors steel substrates when balancing upfront material costs against lifecycle performance in enamel coating projects.

Common Applications of Enamel on Steel vs Aluminum

Enamel on steel substrates is predominantly used in cookware, appliances, and industrial equipment due to its high durability, resistance to corrosion, and thermal stability. Enamel coatings on aluminum substrates are common in decorative applications, architectural panels, and signage, benefiting from aluminum's lightweight properties and excellent corrosion resistance. Both substrates leverage enamel's protective and aesthetic qualities, but steel is favored for heavy-duty and heat-resistant uses, while aluminum is preferred for lightweight and design-focused applications.

Choosing the Right Substrate for Enamel Products

Selecting the appropriate substrate for enamel products depends on durability, weight, and corrosion resistance requirements. Steel substrates offer superior strength and impact resistance, making them ideal for heavy-duty applications, while aluminum substrates provide lightweight and excellent corrosion resistance for environments prone to moisture. Understanding the specific use case ensures optimal performance and longevity of the enamel coating on each substrate type.

Steel substrate vs Aluminum substrate Infographic

materialdif.com

materialdif.com