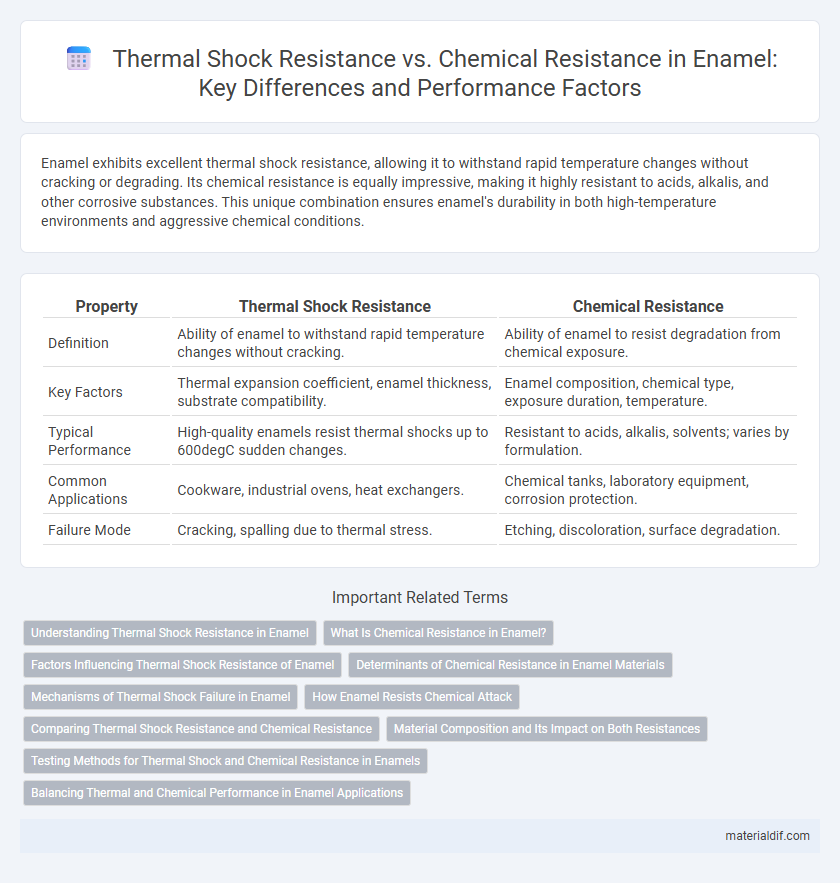

Enamel exhibits excellent thermal shock resistance, allowing it to withstand rapid temperature changes without cracking or degrading. Its chemical resistance is equally impressive, making it highly resistant to acids, alkalis, and other corrosive substances. This unique combination ensures enamel's durability in both high-temperature environments and aggressive chemical conditions.

Table of Comparison

| Property | Thermal Shock Resistance | Chemical Resistance |

|---|---|---|

| Definition | Ability of enamel to withstand rapid temperature changes without cracking. | Ability of enamel to resist degradation from chemical exposure. |

| Key Factors | Thermal expansion coefficient, enamel thickness, substrate compatibility. | Enamel composition, chemical type, exposure duration, temperature. |

| Typical Performance | High-quality enamels resist thermal shocks up to 600degC sudden changes. | Resistant to acids, alkalis, solvents; varies by formulation. |

| Common Applications | Cookware, industrial ovens, heat exchangers. | Chemical tanks, laboratory equipment, corrosion protection. |

| Failure Mode | Cracking, spalling due to thermal stress. | Etching, discoloration, surface degradation. |

Understanding Thermal Shock Resistance in Enamel

Thermal shock resistance in enamel refers to its ability to withstand rapid temperature changes without cracking or damaging the surface. This property is crucial for applications involving sudden heating or cooling, as the enamel's glassy layer must expand or contract uniformly to prevent stress fractures. Understanding the balance between thermal shock resistance and chemical resistance helps optimize enamel formulations for both durability and longevity in harsh environments.

What Is Chemical Resistance in Enamel?

Chemical resistance in enamel refers to its ability to withstand exposure to various chemicals without degrading, corroding, or discoloring. This property is crucial for applications involving acids, alkalis, solvents, and cleaning agents, ensuring durability and maintaining the enamel's protective and decorative qualities. Thermal shock resistance, on the other hand, measures enamel's capacity to endure rapid temperature changes without cracking or spalling, which is essential in environments with fluctuating heat conditions.

Factors Influencing Thermal Shock Resistance of Enamel

Thermal shock resistance of enamel is primarily influenced by its coefficient of thermal expansion, which must be closely matched to the substrate to prevent cracking during rapid temperature changes. The enamel's thickness and cooling rate also play critical roles, as thicker coatings and rapid cooling can increase internal stresses. Chemical composition, especially the balance of silica, alumina, and fluxes, affects the enamel's ability to absorb strain without fracturing, thereby enhancing its thermal shock durability.

Determinants of Chemical Resistance in Enamel Materials

Chemical resistance in enamel materials is primarily determined by the composition of the glassy phase and the presence of specific oxides such as silica, alumina, and boron oxide. The chemical durability also depends on the enamel's firing temperature, which affects the network structure and density, enhancing resistance to acids, alkalis, and solvents. Thermal shock resistance, although important, is influenced more by the thermal expansion coefficient and substrate compatibility rather than the chemical properties of the enamel itself.

Mechanisms of Thermal Shock Failure in Enamel

Thermal shock resistance in enamel primarily depends on its ability to withstand rapid temperature changes without cracking, which occurs due to the mismatch in thermal expansion coefficients between the enamel layer and its substrate causing internal stresses. Crack initiation and propagation arise from tensile stresses exceeding the enamel's fracture toughness, leading to spallation or delamination. Chemical resistance in enamel involves resistance to corrosive environments by forming a stable, inert glassy surface, but this mechanism does not mitigate mechanical stresses induced by thermal shock, making the understanding of thermal stress distribution critical in enamel durability.

How Enamel Resists Chemical Attack

Enamel resists chemical attack through its dense, glass-like surface that acts as an impervious barrier to acids, alkalis, and solvents, preventing corrosive substances from reaching the underlying material. The chemical resistance of enamel is attributed to its vitrified silica network, which provides high stability and prevents chemical degradation. This makes enamel coatings ideal for protecting metal substrates in harsh industrial and household environments where exposure to aggressive chemicals is common.

Comparing Thermal Shock Resistance and Chemical Resistance

Enamel demonstrates higher thermal shock resistance due to its ability to withstand rapid temperature changes without cracking, making it ideal for cookware and industrial applications involving fluctuating heat. In contrast, its chemical resistance is characterized by durability against corrosive substances and acids, ensuring long-lasting surface protection in harsh environments. While thermal shock resistance is crucial for mechanical stability, chemical resistance emphasizes preserving the enamel's integrity against chemical degradation.

Material Composition and Its Impact on Both Resistances

Enamel composed primarily of silica, alumina, and fluxes exhibits enhanced thermal shock resistance due to its ability to accommodate rapid temperature changes without cracking, while higher boron oxide and alkali content can improve chemical resistance by creating a more inert surface. The balance between glassy and crystalline phases in the enamel's microstructure plays a critical role, where a controlled crystalline structure boosts thermal stability and reduces chemical reactivity. Optimizing the material composition by adjusting the ratios of oxides directly impacts both thermal shock resistance and chemical resistance, making it essential for applications requiring durability under thermal cycling and exposure to corrosive substances.

Testing Methods for Thermal Shock and Chemical Resistance in Enamels

Thermal shock resistance in enamels is typically tested by subjecting coated samples to rapid temperature changes, often involving repeated cycles between extreme heat and cold to evaluate crack formation or delamination. Chemical resistance testing involves immersing enamel-coated specimens in aggressive substances like acids, alkalis, or solvents for specified durations to assess surface degradation, discoloration, or loss of adhesion. Standardized methods such as ASTM C704 for thermal shock and ISO 28706-1 for chemical resistance ensure consistent and comparable evaluation of enamel durability under operational stresses.

Balancing Thermal and Chemical Performance in Enamel Applications

Enamel coatings demonstrate varying degrees of thermal shock resistance and chemical resistance, where optimizing the balance between these properties is crucial for durability in industrial applications. High thermal shock resistance in enamel prevents cracking and spalling during rapid temperature fluctuations, while robust chemical resistance ensures protection against corrosive substances and acids. Selecting enamel compositions with tailored glass matrices and additive blends enables enhanced performance, maintaining structural integrity and surface preservation under combined thermal and chemical stress.

Thermal shock resistance vs chemical resistance (in enamel) Infographic

materialdif.com

materialdif.com