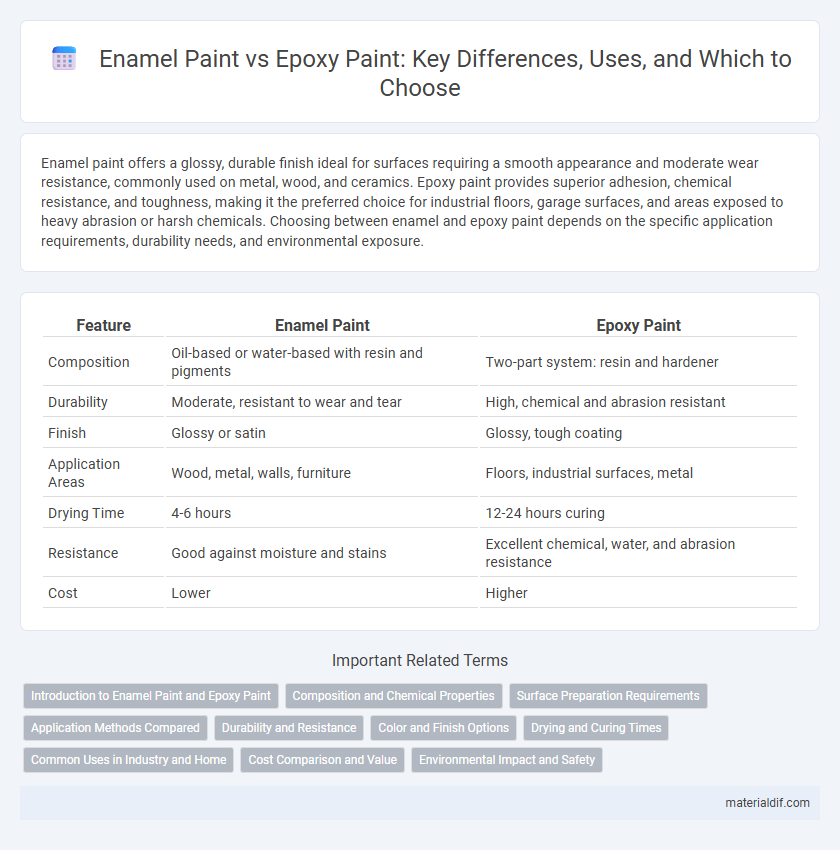

Enamel paint offers a glossy, durable finish ideal for surfaces requiring a smooth appearance and moderate wear resistance, commonly used on metal, wood, and ceramics. Epoxy paint provides superior adhesion, chemical resistance, and toughness, making it the preferred choice for industrial floors, garage surfaces, and areas exposed to heavy abrasion or harsh chemicals. Choosing between enamel and epoxy paint depends on the specific application requirements, durability needs, and environmental exposure.

Table of Comparison

| Feature | Enamel Paint | Epoxy Paint |

|---|---|---|

| Composition | Oil-based or water-based with resin and pigments | Two-part system: resin and hardener |

| Durability | Moderate, resistant to wear and tear | High, chemical and abrasion resistant |

| Finish | Glossy or satin | Glossy, tough coating |

| Application Areas | Wood, metal, walls, furniture | Floors, industrial surfaces, metal |

| Drying Time | 4-6 hours | 12-24 hours curing |

| Resistance | Good against moisture and stains | Excellent chemical, water, and abrasion resistance |

| Cost | Lower | Higher |

Introduction to Enamel Paint and Epoxy Paint

Enamel paint is a durable, oil-based coating known for its glossy finish and resistance to moisture, commonly used on metal, wood, and ceramics. Epoxy paint is a two-component system that chemically cures to form a hard, chemical-resistant surface ideal for industrial floors and surfaces exposed to harsh conditions. Both paints offer strong adhesion and protective qualities but differ significantly in composition, application, and durability.

Composition and Chemical Properties

Enamel paint is primarily composed of alkyd resins dissolved in solvents, offering a hard, glossy finish with moderate chemical resistance due to its oxidative curing process. Epoxy paint consists of epoxy resins and polyamine hardeners that chemically react to form a dense, cross-linked polymer network, providing superior adhesion, durability, and resistance to chemicals and moisture. The chemical properties of epoxy paints enable them to withstand harsh environments better than enamel paints, making them ideal for industrial and protective coatings.

Surface Preparation Requirements

Enamel paint requires a clean, dry, and smooth surface, often needing light sanding to ensure proper adhesion and durability. Epoxy paint demands more thorough surface preparation, including degreasing, removing rust or old coatings, and sometimes roughening the surface with abrasive blasting for optimal bonding. Proper surface preparation is crucial for both paints but is generally more intensive and critical with epoxy due to its chemical bonding properties.

Application Methods Compared

Enamel paint typically requires brushing or spraying for smooth, glossy finishes on wood and metal surfaces, offering easy application with moderate drying times. Epoxy paint necessitates mixing two components before application, often applied using rollers or brushes, providing a durable, chemical-resistant coating ideal for industrial or high-traffic areas. The application of epoxy paint is more labor-intensive and demands precise surface preparation compared to enamel paint.

Durability and Resistance

Enamel paint offers strong durability with a glossy finish that resists chipping and fading, making it ideal for interior surfaces exposed to moderate wear. Epoxy paint surpasses enamel in resistance, providing exceptional protection against chemicals, water, and heavy abrasion, commonly used in industrial and high-traffic areas. The superior hardness and adhesive properties of epoxy contribute to its lasting performance in harsh environments compared to enamel.

Color and Finish Options

Enamel paint offers a wide range of vibrant color options with a smooth, glossy finish ideal for decorative surfaces, while epoxy paint provides a limited color palette but excels with its durable, high-gloss, and chemical-resistant finish suited for industrial and high-traffic areas. Enamel finishes maintain color brilliance over time but can be more prone to chipping compared to epoxy, which delivers a tougher, long-lasting surface. Selecting between enamel and epoxy depends on the desired aesthetic vibrancy versus the need for superior durability and protection.

Drying and Curing Times

Enamel paint typically dries to the touch within 1 to 2 hours and fully cures in about 24 to 48 hours, making it suitable for quick projects. Epoxy paint requires longer drying and curing times, often needing 12 to 24 hours to dry and up to 7 days to fully cure for optimal hardness and chemical resistance. Choosing between enamel and epoxy paint depends on the project's time constraints and durability requirements, with epoxy offering superior toughness after complete curing.

Common Uses in Industry and Home

Enamel paint is commonly used for furniture, appliances, and trim due to its smooth finish and durability in everyday environments, making it ideal for both interior and exterior home applications. Epoxy paint is favored in industrial settings such as factories, warehouses, and garages because of its superior chemical resistance, hardness, and adhesion to concrete and metal surfaces. Both paints serve essential roles in protecting and beautifying surfaces, with enamel paint excelling in decorative and light-duty purposes, while epoxy paint provides heavy-duty protection against wear, moisture, and chemicals.

Cost Comparison and Value

Enamel paint generally costs less than epoxy paint, making it a budget-friendly option for residential projects and everyday use. Epoxy paint, despite its higher price, offers superior durability, chemical resistance, and longevity, providing better value for industrial and high-traffic areas. When weighing cost against performance, epoxy paint's extended lifespan often justifies the initial investment compared to the more affordable but less resilient enamel paint.

Environmental Impact and Safety

Enamel paint typically contains volatile organic compounds (VOCs) that contribute to air pollution and pose health risks, while epoxy paint generally has lower VOC emissions, making it a safer choice for indoor applications. The chemical composition of epoxy paint allows for greater durability and resistance to environmental factors, reducing the need for frequent repainting and minimizing environmental waste. Proper ventilation and protective gear are essential when applying either type, but epoxy paints often require fewer hazardous solvents, enhancing overall safety during and after application.

Enamel Paint vs Epoxy Paint Infographic

materialdif.com

materialdif.com