Enamel coating provides a durable, glossy layer that protects surfaces from corrosion and wear, making it ideal for appliances and industrial equipment. Enamel painting emphasizes artistic expression with vibrant colors and smooth finishes suitable for decorative artwork and crafts. Both methods use enamel materials but differ primarily in application purpose and performance characteristics.

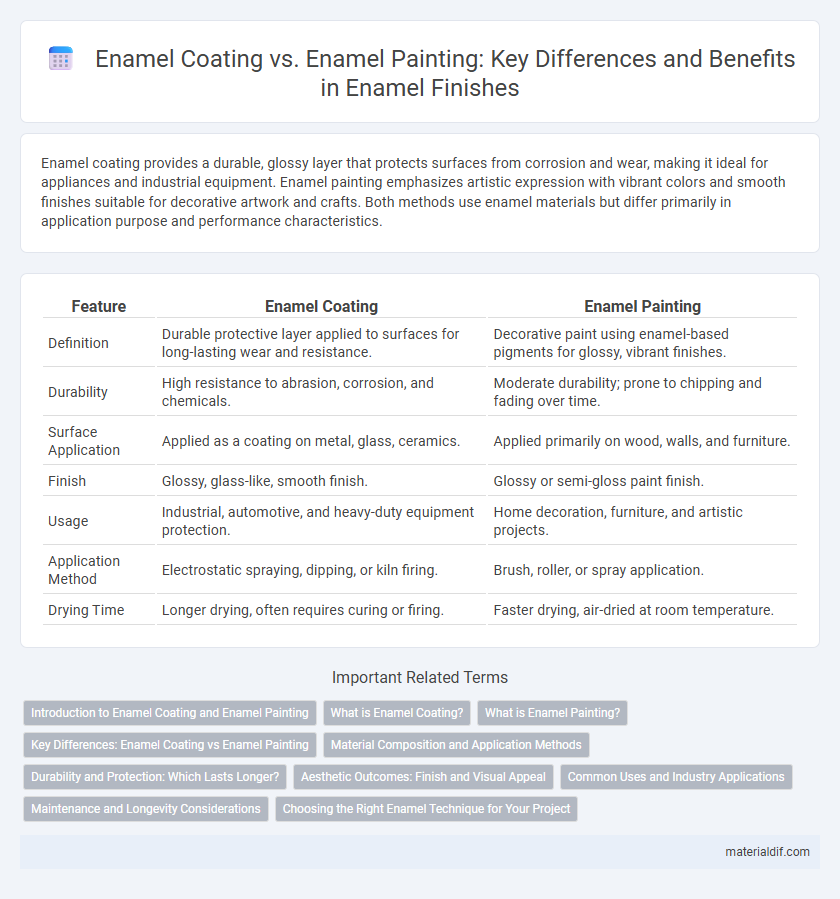

Table of Comparison

| Feature | Enamel Coating | Enamel Painting |

|---|---|---|

| Definition | Durable protective layer applied to surfaces for long-lasting wear and resistance. | Decorative paint using enamel-based pigments for glossy, vibrant finishes. |

| Durability | High resistance to abrasion, corrosion, and chemicals. | Moderate durability; prone to chipping and fading over time. |

| Surface Application | Applied as a coating on metal, glass, ceramics. | Applied primarily on wood, walls, and furniture. |

| Finish | Glossy, glass-like, smooth finish. | Glossy or semi-gloss paint finish. |

| Usage | Industrial, automotive, and heavy-duty equipment protection. | Home decoration, furniture, and artistic projects. |

| Application Method | Electrostatic spraying, dipping, or kiln firing. | Brush, roller, or spray application. |

| Drying Time | Longer drying, often requires curing or firing. | Faster drying, air-dried at room temperature. |

Introduction to Enamel Coating and Enamel Painting

Enamel coating refers to a durable, glass-like finish applied to surfaces, often metals, through a high-temperature baking process that creates a hard, protective layer resistant to corrosion and wear. Enamel painting involves the use of oil-based or water-based enamel paints that dry to a glossy, hard finish ideal for decorative or protective purposes on various materials. Both enamel coating and enamel painting enhance surface durability and aesthetic appeal but differ significantly in application methods and longevity.

What is Enamel Coating?

Enamel coating is a durable, protective layer applied to surfaces such as metal, glass, or ceramics to enhance resistance against corrosion, wear, and environmental damage. Unlike enamel painting, which primarily focuses on aesthetics and surface color, enamel coating provides a hardened, glossy finish that extends the material's lifespan and improves durability. This coating is commonly used in industrial applications and household appliances where long-term protection is essential.

What is Enamel Painting?

Enamel painting involves applying a durable, glossy paint that dries to a hard, shiny finish, typically made from oil-based or synthetic resins. This technique is commonly used on surfaces such as wood, metal, and ceramics to provide long-lasting protection and vibrant color. Unlike enamel coating, which refers to a specific protective layer often applied as a glaze or fuse on materials like glass or metal, enamel painting focuses on the decorative and functional application of enamel-based paint.

Key Differences: Enamel Coating vs Enamel Painting

Enamel coating refers to a durable, glossy finish applied as a protective layer on surfaces like metal and ceramics, providing resistance to corrosion and wear. Enamel painting involves using enamel-based paint to create decorative or artistic finishes on various materials, emphasizing color richness and smooth texture. The key difference lies in enamel coating's functional protection versus enamel painting's aesthetic enhancement.

Material Composition and Application Methods

Enamel coating typically involves a durable, glass-like layer formed by fusing powdered glass to a substrate through high-temperature firing, offering superior hardness and corrosion resistance ideal for metal surfaces. Enamel painting, conversely, consists of oil-based or synthetic resins mixed with pigments, applied by brush or spray, providing a glossy finish with easier application but less thermal and chemical resistance. Material composition differences impact application methods significantly: enamel coating requires kiln firing for curing, whereas enamel paint dries through solvent evaporation at ambient temperatures.

Durability and Protection: Which Lasts Longer?

Enamel coating offers superior durability compared to enamel painting because it forms a harder, more resistant surface that withstands scratches, chemicals, and weathering better. Enamel painting, while providing aesthetic appeal, typically has a thinner layer that is more prone to chipping and fading over time. For long-lasting protection on metal, wood, or ceramics, enamel coating is the preferred choice due to its enhanced resistance and longevity.

Aesthetic Outcomes: Finish and Visual Appeal

Enamel coating delivers a durable, glossy finish that resists chipping and maintains color vibrancy over time, making it ideal for high-traffic surfaces. Enamel painting offers greater versatility in texture and color blending, allowing for customized artistic effects with varying degrees of sheen. Both methods enhance aesthetic appeal but differ in finish durability and stylistic flexibility.

Common Uses and Industry Applications

Enamel coating is widely used for industrial applications such as protecting machinery, automotive parts, and appliances due to its durable, glossy finish and resistance to corrosion and wear. Enamel painting is primarily favored in artistic and decorative contexts, including furniture, artwork, and household objects, offering vibrant colors and smooth textures. Both processes provide robust surfaces but differ in their formulation and application techniques tailored to either industrial durability or aesthetic appeal.

Maintenance and Longevity Considerations

Enamel coating offers superior durability and resistance to scratches, stains, and moisture, making it easier to maintain and ideal for high-traffic or outdoor surfaces. Enamel paint, while also providing a hard and glossy finish, may require more frequent touch-ups and can be prone to chipping over time in demanding environments. For longevity, enamel coatings form a thicker protective layer that significantly extends the lifespan of the underlying material compared to enamel paint applied as a thinner surface layer.

Choosing the Right Enamel Technique for Your Project

Enamel coating provides a durable, glossy finish ideal for protecting surfaces from corrosion and wear, making it suitable for industrial applications and metal objects. Enamel painting offers vibrant color options and smooth texture, perfect for decorative art projects and home decor pieces. Selecting the right enamel technique depends on your project's functional needs and aesthetic goals, with coating favored for durability and painting chosen for artistic expression.

Enamel coating vs Enamel painting Infographic

materialdif.com

materialdif.com