Low-fire enamel is applied and fired at temperatures between 1,600degF and 1,900degF, resulting in vibrant colors and a smooth, glossy finish ideal for detailed artwork on pet collars or tags. High-fire enamel requires temperatures above 2,100degF, producing a more durable, matte finish that withstands wear and heat better but may have a limited color palette. Choosing between low-fire and high-fire enamel depends on the desired aesthetic and durability for pet accessories.

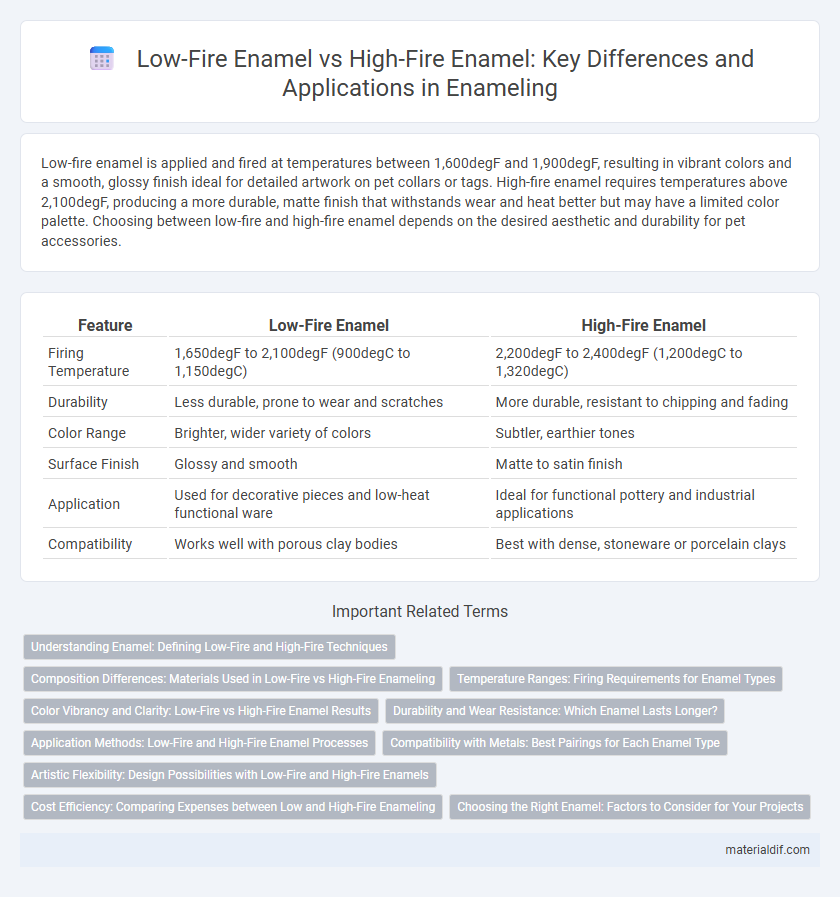

Table of Comparison

| Feature | Low-Fire Enamel | High-Fire Enamel |

|---|---|---|

| Firing Temperature | 1,650degF to 2,100degF (900degC to 1,150degC) | 2,200degF to 2,400degF (1,200degC to 1,320degC) |

| Durability | Less durable, prone to wear and scratches | More durable, resistant to chipping and fading |

| Color Range | Brighter, wider variety of colors | Subtler, earthier tones |

| Surface Finish | Glossy and smooth | Matte to satin finish |

| Application | Used for decorative pieces and low-heat functional ware | Ideal for functional pottery and industrial applications |

| Compatibility | Works well with porous clay bodies | Best with dense, stoneware or porcelain clays |

Understanding Enamel: Defining Low-Fire and High-Fire Techniques

Low-fire enamel typically matures between 1,600degF and 1,900degF, allowing for vibrant colors and detailed designs due to its lower firing temperature. High-fire enamel requires temperatures above 2,100degF, producing a more durable, glass-like finish ideal for items exposed to wear and heat. Understanding these temperature ranges and their effects on enamel properties is essential for selecting the appropriate technique for artistic or industrial applications.

Composition Differences: Materials Used in Low-Fire vs High-Fire Enameling

Low-fire enamel typically contains softer glass frits and fluxes such as lead or borax, allowing it to melt at temperatures between 1150degF and 1300degF, whereas high-fire enamel incorporates harder materials like feldspar and silica, requiring firing temperatures above 1400degF. The composition of low-fire enamel includes a higher proportion of colorants and opacifiers, which can degrade at high temperatures, while high-fire enamel utilizes more stable inorganic compounds for durability and resistance to thermal shock. These material differences influence the enamel's final texture, color vibrancy, and suitability for various ceramic or metal surfaces.

Temperature Ranges: Firing Requirements for Enamel Types

Low-fire enamel requires firing temperatures between 1300degF and 1500degF (704degC to 815degC), making it suitable for delicate substrates like glass and metal alloys sensitive to heat. High-fire enamel demands higher temperatures ranging from 1400degF to 1600degF (760degC to 870degC), offering enhanced durability and resistance to wear and corrosion. Understanding these temperature ranges ensures optimal adhesion and longevity of enamel coatings on various materials.

Color Vibrancy and Clarity: Low-Fire vs High-Fire Enamel Results

Low-fire enamel firing temperatures typically range between 1400degF and 1500degF, preserving brighter and more vivid color vibrancy due to less pigment degradation. In contrast, high-fire enamel, fired above 1500degF, often results in deeper, more muted tones as the intense heat can cause some colors to darken or shift. The clarity in low-fire enamels tends to be sharper with distinct color boundaries, while high-fire enamels offer a smoother, often more blended appearance with subtle color transitions.

Durability and Wear Resistance: Which Enamel Lasts Longer?

High-fire enamel, typically fired between 1,200degC and 1,500degC, offers superior durability and wear resistance due to its denser and more fused glass layer, making it ideal for heavy-use surfaces. Low-fire enamel, fired below 1,200degC, provides vibrant colors but generally exhibits less hardness and resistance to abrasion, leading to shorter lifespan under rigorous conditions. Therefore, high-fire enamel lasts longer in applications demanding enhanced durability and prolonged wear resistance.

Application Methods: Low-Fire and High-Fire Enamel Processes

Low-fire enamel is typically applied through techniques such as brushing, dipping, or spraying at lower temperatures ranging from 1,500degF to 1,830degF (815degC to 1,000degC), which allows for vibrant colors and detailed surface designs. High-fire enamel requires firing at temperatures above 1,830degF (1,000degC), often between 1,980degF and 2,192degF (1,080degC to 1,200degC), and is usually applied via sifting or powdering to create durable, glossy finishes suited for functional ceramics. The choice between low-fire and high-fire enamel processes directly influences the enamel's adhesion, color stability, and suitability for different types of ceramic bodies and artistic techniques.

Compatibility with Metals: Best Pairings for Each Enamel Type

Low-fire enamel is best paired with metals like copper, brass, and sterling silver due to its firing temperature of 1350degF to 1500degF, which reduces the risk of metal warping or melting. High-fire enamel requires compatible metals such as fine silver, fine gold, and certain steel alloys that can withstand temperatures between 1450degF and 1600degF without compromising their structural integrity. Choosing the right metal based on enamel firing temperature ensures optimal adhesion, durability, and finish quality.

Artistic Flexibility: Design Possibilities with Low-Fire and High-Fire Enamels

Low-fire enamel offers greater artistic flexibility due to its lower firing temperatures, allowing for a broader range of vibrant colors and delicate details that may not withstand high heat. High-fire enamel, fired between 1400degF and 1600degF, produces durable, glossy finishes ideal for robust applications but limits color variety and fine detail complexity. Artists often choose low-fire enamel for intricate designs and multi-layered effects, while high-fire enamel suits pieces requiring longevity and resistance to wear.

Cost Efficiency: Comparing Expenses between Low and High-Fire Enameling

Low-fire enamel typically costs less overall due to lower kiln temperatures and reduced energy consumption, making it more cost-efficient for small-scale or hobby projects. High-fire enamel requires more energy and specialized kilns, increasing the expenses despite offering greater durability and resistance. Choosing between low and high-fire enameling depends on balancing material costs, energy usage, and desired finish quality.

Choosing the Right Enamel: Factors to Consider for Your Projects

Low-fire enamel typically matures at temperatures between 1,630degF and 1,900degF (890degC to 1,040degC), offering vibrant colors and detailed surface designs ideal for decorative ceramics and jewelry. High-fire enamel, maturing above 2,192degF (1,200degC), provides superior durability, resistance to scratches, and chemical stability suitable for functional pottery and industrial applications. Selecting the right enamel depends on the compatibility with the base material, the desired finish durability, and the firing equipment available for your specific project requirements.

Low-fire enamel vs high-fire enamel Infographic

materialdif.com

materialdif.com