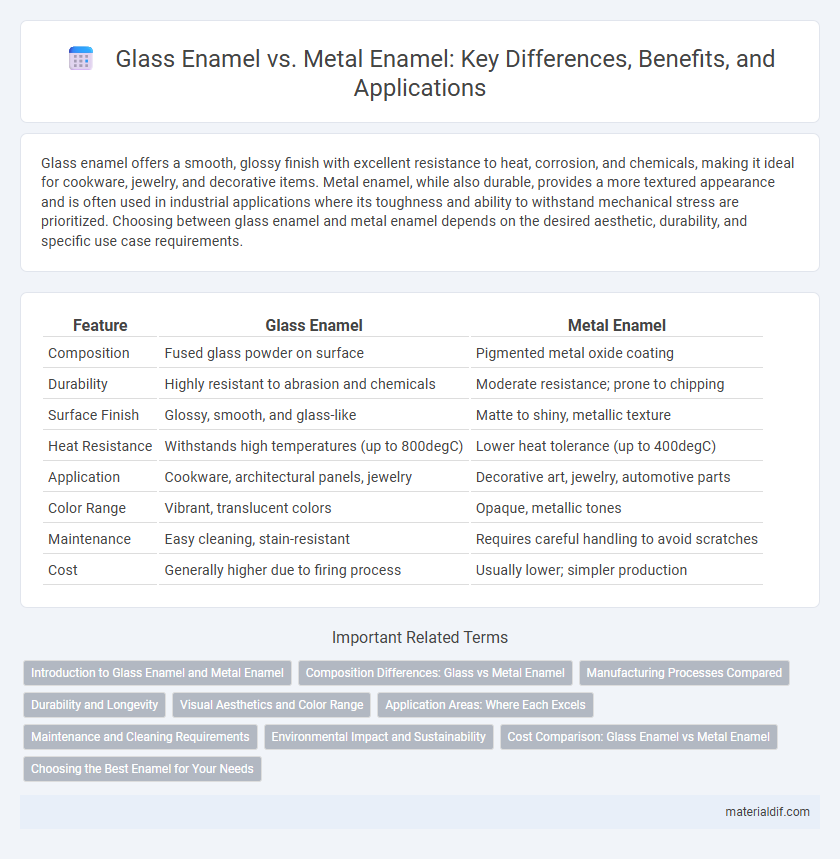

Glass enamel offers a smooth, glossy finish with excellent resistance to heat, corrosion, and chemicals, making it ideal for cookware, jewelry, and decorative items. Metal enamel, while also durable, provides a more textured appearance and is often used in industrial applications where its toughness and ability to withstand mechanical stress are prioritized. Choosing between glass enamel and metal enamel depends on the desired aesthetic, durability, and specific use case requirements.

Table of Comparison

| Feature | Glass Enamel | Metal Enamel |

|---|---|---|

| Composition | Fused glass powder on surface | Pigmented metal oxide coating |

| Durability | Highly resistant to abrasion and chemicals | Moderate resistance; prone to chipping |

| Surface Finish | Glossy, smooth, and glass-like | Matte to shiny, metallic texture |

| Heat Resistance | Withstands high temperatures (up to 800degC) | Lower heat tolerance (up to 400degC) |

| Application | Cookware, architectural panels, jewelry | Decorative art, jewelry, automotive parts |

| Color Range | Vibrant, translucent colors | Opaque, metallic tones |

| Maintenance | Easy cleaning, stain-resistant | Requires careful handling to avoid scratches |

| Cost | Generally higher due to firing process | Usually lower; simpler production |

Introduction to Glass Enamel and Metal Enamel

Glass enamel is a vitreous coating composed of powdered glass fused to a substrate by firing, known for its durability, chemical resistance, and smooth glossy finish. Metal enamel, also called vitreous or porcelain enamel on metals, involves fusing glass powders onto metal surfaces such as steel, cast iron, or aluminum to protect against corrosion and provide an aesthetic appeal. Both types of enamel offer unique benefits in industrial applications, with glass enamel primarily used on non-metallic surfaces and metal enamel specifically engineered for metallic substrates.

Composition Differences: Glass vs Metal Enamel

Glass enamel consists primarily of finely ground glass mixed with fluxes and pigments, which fuses to surfaces at high temperatures creating a smooth, glossy coating. Metal enamel, often referred to as vitreous or industrial enamel, incorporates metallic oxides and is applied to metals like steel or cast iron to enhance durability and corrosion resistance. The key compositional difference lies in glass enamel's silica-based glass matrix versus metal enamel's formulation tailored for stronger adhesion and hardness on metal substrates.

Manufacturing Processes Compared

Glass enamel manufacturing involves fusing powdered glass to a substrate through high-temperature firing, creating a smooth, durable coating resistant to corrosion and thermal shock. Metal enamel production methods typically include electroplating or chemical deposition, forming a metallic oxide layer that enhances adhesion and wear resistance on metal surfaces. Both processes require precise temperature control and surface preparation, but glass enamel demands higher firing temperatures around 750-850degC, while metal enamel coatings are often applied at lower temperatures or through room-temperature chemical reactions.

Durability and Longevity

Glass enamel offers superior durability compared to metal enamel due to its resistance to corrosion, chipping, and fading over time. Metal enamel, while flexible and easier to apply on complex shapes, generally has a shorter lifespan as it is more prone to wear and environmental damage. The longevity of glass enamel makes it ideal for applications requiring strong, lasting protection and vibrant finishes.

Visual Aesthetics and Color Range

Glass enamel offers a smooth, glossy finish with vibrant, translucent colors that enhance light reflection, creating a visually striking appearance ideal for decorative applications. Metal enamel provides a more durable finish with rich, opaque pigments that resist fading, making it suitable for industrial and outdoor uses. The color range in glass enamel is often more varied and bright, while metal enamel typically presents deeper, more muted tones tailored for longevity and toughness.

Application Areas: Where Each Excels

Glass enamel excels in decorative applications and cookware due to its excellent heat resistance, vibrant color retention, and strong chemical durability, ideal for kitchenware and architectural panels. Metal enamel is preferred in industrial and automotive sectors for protective coatings on machinery and vehicles, providing superior mechanical strength and corrosion resistance on metal surfaces. Each type's unique properties align with specific application areas where either aesthetic appeal or heavy-duty protection is paramount.

Maintenance and Cleaning Requirements

Glass enamel offers superior resistance to stains and scratches, making its maintenance and cleaning more straightforward with just mild detergent and non-abrasive cloths. Metal enamel, while durable, requires more careful upkeep to avoid chipping and corrosion, often needing specialized cleaners and protective coatings. Both types benefit from regular cleaning to preserve their glossy finish, but glass enamel demands less frequent and less intensive maintenance overall.

Environmental Impact and Sustainability

Glass enamel offers a more environmentally sustainable option compared to metal enamel due to its lower VOC emissions and non-toxic composition during production and disposal. The durability and recyclability of glass enamel reduce waste and resource consumption over time, minimizing its ecological footprint. In contrast, metal enamel often involves mining and processing of metals with higher energy demands and potential heavy metal contamination risks.

Cost Comparison: Glass Enamel vs Metal Enamel

Glass enamel generally incurs higher production costs due to its complex firing process and the need for specialized kiln equipment, whereas metal enamel tends to be more affordable because it uses simpler techniques and lower-temperature firings. Metal enamel coatings provide cost-effective durability suitable for industrial applications, while glass enamel is preferred for decorative items despite its higher price. Choosing between glass and metal enamel should consider budget constraints alongside performance and aesthetic requirements.

Choosing the Best Enamel for Your Needs

Glass enamel offers superior durability and resistance to heat and chemicals, making it ideal for cookware, appliances, and decorative surfaces requiring long-lasting protection. Metal enamel, typically applied as a powder coating or liquid paint, provides enhanced flexibility and adhesion on complex metal shapes, suitable for automotive parts and industrial equipment. Selecting the best enamel depends on factors like substrate compatibility, environmental exposure, and desired finish, with glass enamel favored for hardness and metal enamel chosen for versatility and ease of application.

Glass Enamel vs Metal Enamel Infographic

materialdif.com

materialdif.com