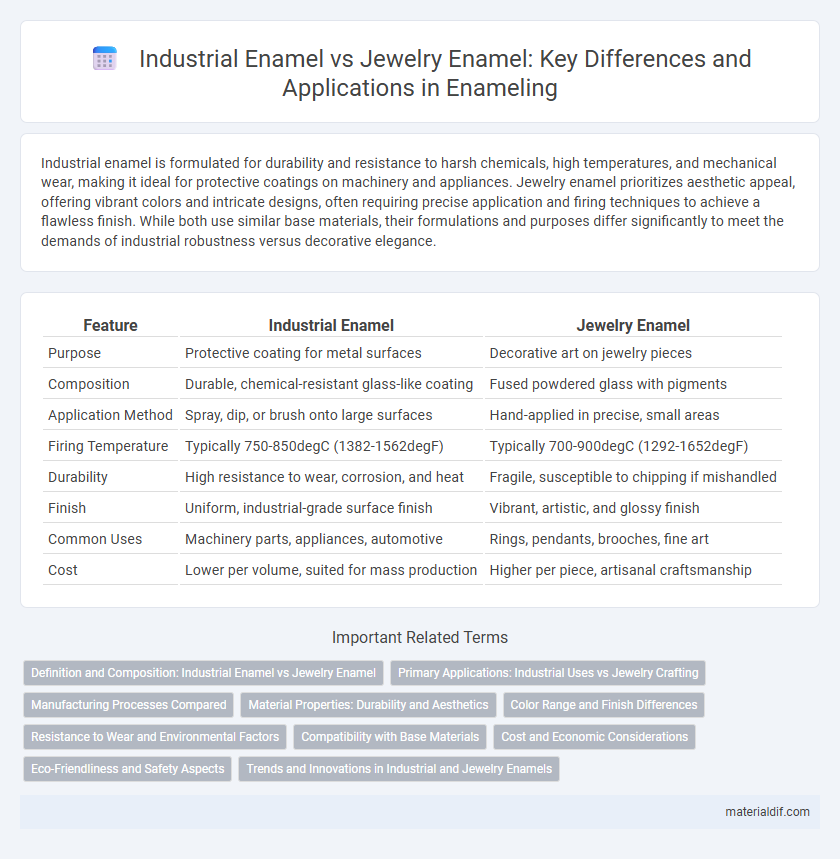

Industrial enamel is formulated for durability and resistance to harsh chemicals, high temperatures, and mechanical wear, making it ideal for protective coatings on machinery and appliances. Jewelry enamel prioritizes aesthetic appeal, offering vibrant colors and intricate designs, often requiring precise application and firing techniques to achieve a flawless finish. While both use similar base materials, their formulations and purposes differ significantly to meet the demands of industrial robustness versus decorative elegance.

Table of Comparison

| Feature | Industrial Enamel | Jewelry Enamel |

|---|---|---|

| Purpose | Protective coating for metal surfaces | Decorative art on jewelry pieces |

| Composition | Durable, chemical-resistant glass-like coating | Fused powdered glass with pigments |

| Application Method | Spray, dip, or brush onto large surfaces | Hand-applied in precise, small areas |

| Firing Temperature | Typically 750-850degC (1382-1562degF) | Typically 700-900degC (1292-1652degF) |

| Durability | High resistance to wear, corrosion, and heat | Fragile, susceptible to chipping if mishandled |

| Finish | Uniform, industrial-grade surface finish | Vibrant, artistic, and glossy finish |

| Common Uses | Machinery parts, appliances, automotive | Rings, pendants, brooches, fine art |

| Cost | Lower per volume, suited for mass production | Higher per piece, artisanal craftsmanship |

Definition and Composition: Industrial Enamel vs Jewelry Enamel

Industrial enamel is a durable coating composed primarily of powdered glass fused onto metal surfaces at high temperatures, designed for corrosion resistance and longevity in applications like appliances and automotive parts. Jewelry enamel, often called vitreous or artistic enamel, blends finely ground glass with metal oxides and colorants, fired at precise temperatures to achieve vibrant hues and intricate designs. Both types share a glass-based composition but differ in formulation and firing techniques to suit industrial durability or decorative artistry.

Primary Applications: Industrial Uses vs Jewelry Crafting

Industrial enamel is primarily utilized for coating machinery, automotive parts, and household appliances, providing durability, corrosion resistance, and a smooth, protective finish suited for heavy-duty applications. Jewelry enamel is crafted for decorative purposes, applied to fine jewelry pieces like rings, pendants, and bracelets to enhance aesthetic appeal with vibrant colors and intricate designs. The industrial enamel prioritizes functionality and longevity, while jewelry enamel emphasizes artistry and delicate craftsmanship.

Manufacturing Processes Compared

Industrial enamel manufacturing involves large-scale application methods such as wet spraying, electrostatic coating, or dip coating on metal surfaces, followed by high-temperature kiln firing to create durable, corrosion-resistant coatings. Jewelry enamel production requires meticulous hand-applied techniques like cloisonne, champleve, or guilloche, with multiple precise firing cycles at controlled temperatures to ensure fine color development and intricate detail preservation. The differences in temperature control, application precision, and batch scale reflect the contrasting durability requirements and artistic complexity in industrial versus jewelry enamel processes.

Material Properties: Durability and Aesthetics

Industrial enamel features high durability with excellent resistance to heat, chemicals, and abrasion, making it ideal for protective coatings on machinery and appliances. Jewelry enamel emphasizes vibrant colors and fine detail, crafted from glass powders fused at lower temperatures to enhance aesthetic appeal without compromising delicate designs. While industrial enamel prioritizes robustness for functional longevity, jewelry enamel balances durability with artistic beauty for decorative purposes.

Color Range and Finish Differences

Industrial enamel typically offers a limited color range focused on durability and corrosion resistance, with finishes that prioritize functionality such as matte or semi-gloss textures. Jewelry enamel provides a broader spectrum of vibrant, translucent colors and glossy finishes designed to enhance aesthetic appeal and mimic precious gemstones. The differences in formulation and firing processes result in industrial enamel emphasizing robustness while jewelry enamel emphasizes intricate color depth and shine.

Resistance to Wear and Environmental Factors

Industrial enamel is specifically formulated to offer superior resistance to wear and harsh environmental factors such as chemicals, UV radiation, and temperature fluctuations, making it ideal for heavy-duty applications. Jewelry enamel prioritizes aesthetic qualities with vibrant colors and intricate designs but generally exhibits lower durability against abrasion and environmental exposure. The chemical composition and curing processes of industrial enamel enhance its hardness and protective capabilities compared to the delicate and decorative nature of jewelry enamel.

Compatibility with Base Materials

Industrial enamel is specifically formulated to adhere to metal surfaces like steel, aluminum, and cast iron, offering heat resistance and durability for heavy-duty applications. Jewelry enamel is designed for compatibility with precious metals such as gold, silver, and copper, ensuring a smooth, glossy finish without damaging delicate substrates. The chemical composition and firing temperatures of jewelry enamel are optimized to maintain the integrity and luster of fine metals, whereas industrial enamel emphasizes corrosion resistance and hardness on robust materials.

Cost and Economic Considerations

Industrial enamel is typically more cost-effective due to bulk production and use of less expensive materials, optimizing economic efficiency for large-scale applications such as machinery coatings and cookware. Jewelry enamel involves higher costs driven by intricate craftsmanship, premium materials, and labor-intensive processes essential for fine art and luxury items. These economic differences influence their market pricing, with industrial enamel focusing on durability and affordability, whereas jewelry enamel emphasizes aesthetic value and exclusivity.

Eco-Friendliness and Safety Aspects

Industrial enamel coatings are formulated for durability and resistance to chemicals and high temperatures, often containing heavy metals and hazardous substances that raise environmental and safety concerns. Jewelry enamel prioritizes non-toxic, lead-free materials with lower environmental impact, aligning with eco-friendly practices and wearer safety. The use of cobalt, nickel, and cadmium is minimized or eliminated in jewelry enamels to reduce allergic reactions and toxicity risks.

Trends and Innovations in Industrial and Jewelry Enamels

Advancements in industrial enamel emphasize enhanced durability, chemical resistance, and heat tolerance, driven by applications in automotive, electronics, and construction industries. Jewelry enamel innovations focus on richer color palettes, finer details, and mixed media techniques to create unique, customizable designs appealing to contemporary fashion trends. Both sectors integrate nanotechnology and eco-friendly materials to improve performance and sustainability, reflecting a growing demand for high-quality, environmentally conscious products.

Industrial enamel vs jewelry enamel Infographic

materialdif.com

materialdif.com