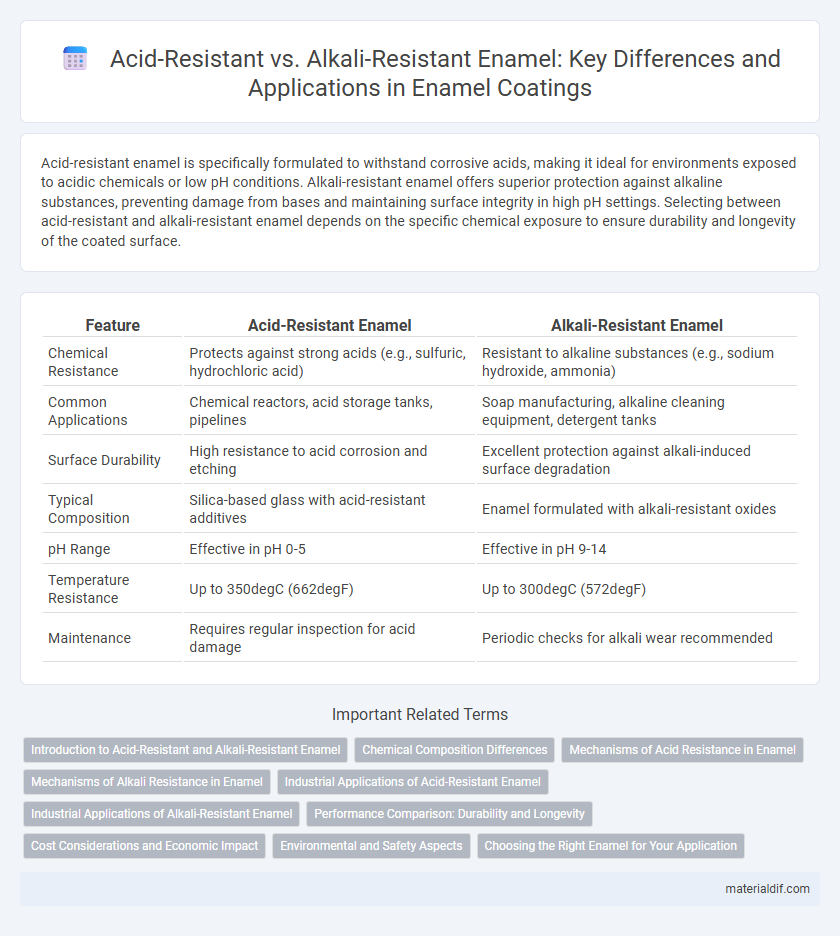

Acid-resistant enamel is specifically formulated to withstand corrosive acids, making it ideal for environments exposed to acidic chemicals or low pH conditions. Alkali-resistant enamel offers superior protection against alkaline substances, preventing damage from bases and maintaining surface integrity in high pH settings. Selecting between acid-resistant and alkali-resistant enamel depends on the specific chemical exposure to ensure durability and longevity of the coated surface.

Table of Comparison

| Feature | Acid-Resistant Enamel | Alkali-Resistant Enamel |

|---|---|---|

| Chemical Resistance | Protects against strong acids (e.g., sulfuric, hydrochloric acid) | Resistant to alkaline substances (e.g., sodium hydroxide, ammonia) |

| Common Applications | Chemical reactors, acid storage tanks, pipelines | Soap manufacturing, alkaline cleaning equipment, detergent tanks |

| Surface Durability | High resistance to acid corrosion and etching | Excellent protection against alkali-induced surface degradation |

| Typical Composition | Silica-based glass with acid-resistant additives | Enamel formulated with alkali-resistant oxides |

| pH Range | Effective in pH 0-5 | Effective in pH 9-14 |

| Temperature Resistance | Up to 350degC (662degF) | Up to 300degC (572degF) |

| Maintenance | Requires regular inspection for acid damage | Periodic checks for alkali wear recommended |

Introduction to Acid-Resistant and Alkali-Resistant Enamel

Acid-resistant enamel is specially formulated to withstand highly acidic environments, commonly used in chemical processing and storage applications where strong acids are present. Alkali-resistant enamel, on the other hand, is designed to resist degradation from alkaline substances, making it ideal for industries handling caustic solutions and detergents. Both types of enamel utilize unique chemical compositions and curing processes to enhance their durability and protective properties against specific corrosive agents.

Chemical Composition Differences

Acid-resistant enamel typically contains a higher concentration of silica and boron compounds, which enhance its chemical stability and durability against acidic substances. Alkali-resistant enamel, on the other hand, incorporates alumina and specific metal oxides like zirconium oxide to provide effective protection against alkaline corrosion. These chemical composition differences directly influence the enamel's resistance properties, determining its suitability for various industrial and laboratory applications.

Mechanisms of Acid Resistance in Enamel

Acid-resistant enamel achieves its durability through a dense mineral structure primarily composed of hydroxyapatite crystals that resist demineralization by maintaining a low solubility in acidic environments. The presence of fluoride ions in acid-resistant enamel enhances remineralization by forming fluorapatite, which is less soluble in acid compared to hydroxyapatite. This enamel type also features a tightly packed crystal lattice that limits acid penetration and reduces enamel erosion caused by acidic substances.

Mechanisms of Alkali Resistance in Enamel

Alkali-resistant enamel demonstrates superior durability due to its unique chemical composition, which includes higher silica content and specialized fluxing agents that form stable aluminosilicate networks. These networks create a dense, glass-like barrier that resists degradation by alkaline substances, preventing surface etching and structural breakdown. The mechanism involves the enamel's inertness towards hydroxide ions, minimizing ion exchange and preserving the enamel's integrity under caustic conditions.

Industrial Applications of Acid-Resistant Enamel

Acid-resistant enamel offers superior protection against corrosive substances in industrial environments, making it ideal for chemical plants, acid storage tanks, and pharmaceutical manufacturing equipment. This enamel type maintains durability and surface integrity when exposed to strong acids like sulfuric and hydrochloric acid, preventing metal corrosion and extending equipment lifespan. Industries handling aggressive acidic substances rely on acid-resistant enamel coatings to ensure safety, reduce maintenance costs, and enhance operational efficiency.

Industrial Applications of Alkali-Resistant Enamel

Alkali-resistant enamel is extensively used in industrial applications requiring protection against corrosive alkaline substances, such as in chemical processing plants, water treatment facilities, and storage tanks for caustic solutions. This type of enamel provides superior resistance to high pH environments, preventing surface degradation and extending equipment lifespan. Its durability and chemical inertness make it essential for safeguarding industrial surfaces exposed to aggressive alkaline conditions.

Performance Comparison: Durability and Longevity

Acid-resistant enamel exhibits superior durability in environments with low pH, maintaining structural integrity and resisting corrosion caused by acidic substances better than alkali-resistant enamel. Alkali-resistant enamel, on the other hand, offers enhanced longevity in high pH conditions, effectively preventing degradation from alkaline exposure. Performance comparison indicates that selecting enamel based on the specific chemical environment optimizes both durability and lifespan.

Cost Considerations and Economic Impact

Acid-resistant enamel typically incurs higher production costs due to specialized raw materials and manufacturing processes, leading to increased initial investment but offering longer lifespan and reduced maintenance expenses in corrosive environments. Alkali-resistant enamel usually has lower upfront costs but may require more frequent repairs or replacement when exposed to strong alkaline substances, impacting overall economic efficiency. Evaluating the cost-benefit ratio involves considering application-specific environmental conditions and maintenance budgets to optimize long-term financial outcomes.

Environmental and Safety Aspects

Acid-resistant enamel provides superior protection against corrosion and chemical degradation in environments with high acidity, minimizing hazardous emissions and enhancing workplace safety. Alkali-resistant enamel offers robustness in alkaline conditions, reducing the risk of structural damage and chemical exposure to personnel. Both types contribute to environmental sustainability by extending equipment lifespan and reducing waste from frequent replacements.

Choosing the Right Enamel for Your Application

Acid-resistant enamel is formulated with higher silica content and specialized frits to withstand corrosive environments, making it ideal for chemical processing and acidic storage applications. Alkali-resistant enamel incorporates boron and alumina to resist caustic substances, suitable for industries dealing with alkaline detergents and cleaning agents. Selecting the right enamel depends on the specific chemical exposure and temperature conditions to ensure durability and maintain surface integrity.

Acid-resistant enamel vs Alkali-resistant enamel Infographic

materialdif.com

materialdif.com