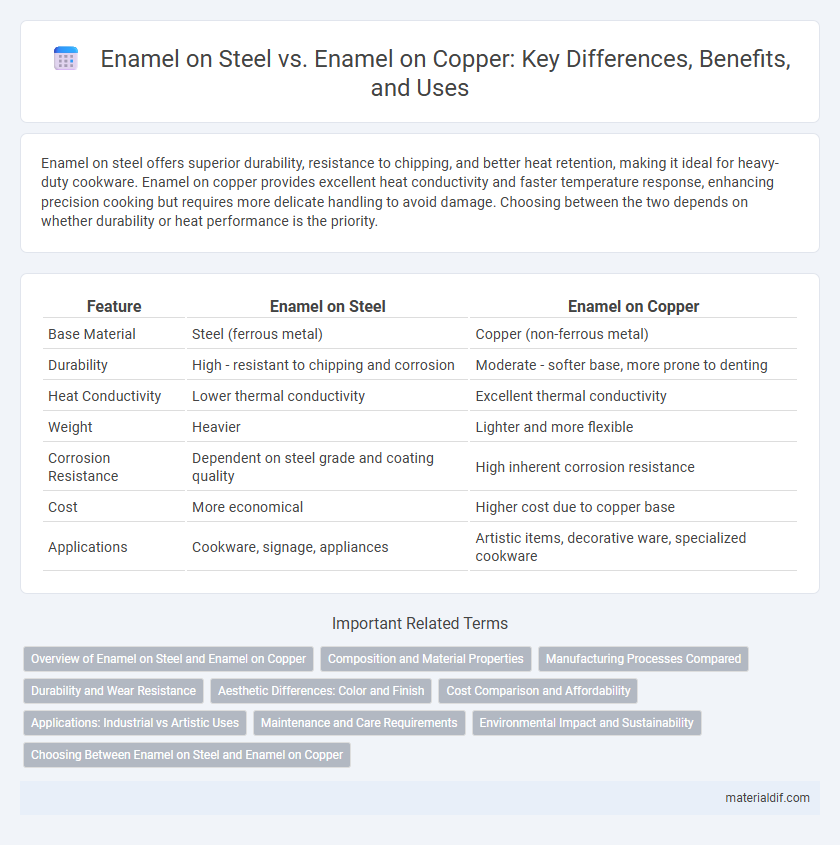

Enamel on steel offers superior durability, resistance to chipping, and better heat retention, making it ideal for heavy-duty cookware. Enamel on copper provides excellent heat conductivity and faster temperature response, enhancing precision cooking but requires more delicate handling to avoid damage. Choosing between the two depends on whether durability or heat performance is the priority.

Table of Comparison

| Feature | Enamel on Steel | Enamel on Copper |

|---|---|---|

| Base Material | Steel (ferrous metal) | Copper (non-ferrous metal) |

| Durability | High - resistant to chipping and corrosion | Moderate - softer base, more prone to denting |

| Heat Conductivity | Lower thermal conductivity | Excellent thermal conductivity |

| Weight | Heavier | Lighter and more flexible |

| Corrosion Resistance | Dependent on steel grade and coating quality | High inherent corrosion resistance |

| Cost | More economical | Higher cost due to copper base |

| Applications | Cookware, signage, appliances | Artistic items, decorative ware, specialized cookware |

Overview of Enamel on Steel and Enamel on Copper

Enamel on steel features a durable, corrosion-resistant surface ideal for industrial and household applications, offering excellent strength and impact resistance. Enamel on copper provides superior thermal conductivity and a smooth, lustrous finish, making it favored in decorative and high-heat contexts, though it is more prone to wear. Both materials benefit from enamel's protective qualities, but steel substrates excel in structural durability while copper enhances aesthetic and thermal performance.

Composition and Material Properties

Enamel on steel features a ferritic or carbon steel base providing high mechanical strength and durability, while enamel on copper uses a ductile, corrosion-resistant copper substrate enhancing thermal conductivity. The composition of enamel applied to both metals typically involves a glassy frit with silica, borates, and alkali oxides, creating a smooth, chemically resistant coating. Steel substrates excel in hardness and impact resistance, whereas copper substrates offer superior heat distribution, making each suitable for specific industrial applications.

Manufacturing Processes Compared

Enamel on steel manufacturing involves coating steel sheets with a powdered glass mixture, then firing them at temperatures around 750degC to create a durable, heat-resistant surface. Enamel on copper requires a more delicate process, as copper's lower melting point demands precise temperature control, typically between 500degC and 600degC, to prevent warping or oxidation during firing. These differences influence production speed, cost, and the enamel's adhesion quality, with steel offering higher durability and copper providing superior thermal conductivity.

Durability and Wear Resistance

Enamel on steel offers superior durability and wear resistance due to steel's high tensile strength and resistance to deformation, making it ideal for heavy-duty applications. In contrast, enamel on copper provides excellent thermal conductivity but tends to be less durable and more prone to wear because copper is softer and more susceptible to scratching and denting. The choice between enamel on steel or copper depends on prioritizing either mechanical resilience or heat transfer efficiency.

Aesthetic Differences: Color and Finish

Enamel on steel typically offers a sleek, modern aesthetic with vibrant colors and a smooth, glossy finish that enhances durability and resistance to chipping. Enamel on copper showcases a warmer, richer color palette, often with subtle variations and a softer, matte or semi-gloss finish, highlighting the natural beauty of the underlying metal. The visual appeal of enamel on copper often appears more artisanal and traditional compared to the industrial, polished look of enamel on steel.

Cost Comparison and Affordability

Enamel on steel typically offers a more cost-effective solution compared to enamel on copper due to steel's lower raw material price and widespread availability, making it ideal for budget-conscious projects. The enamel coating on steel ensures durability and resistance to corrosion at a fraction of the cost associated with copper substrates, which are inherently more expensive. Choosing enamel on steel enhances affordability without significantly compromising quality, especially in large-scale manufacturing or construction applications.

Applications: Industrial vs Artistic Uses

Enamel on steel is predominantly used in industrial applications such as cookware, appliances, and signage due to its durability, heat resistance, and corrosion resistance. Enamel on copper, valued for its superior thermal conductivity and vibrant aesthetic appeal, is favored in artistic contexts like jewelry, decorative items, and fine art enameling. The industrial emphasis on functionality and robustness contrasts with the artistic focus on intricate designs and color vibrancy in enamel on copper works.

Maintenance and Care Requirements

Enamel on steel requires regular inspection for chips and rust prevention, as steel is prone to corrosion when the enamel coating is damaged. Enamel on copper demands careful cleaning to avoid tarnishing the metal beneath, with attention to avoiding abrasive materials that can scratch the enamel surface. Both substrates benefit from gentle hand washing and drying to maintain the integrity and appearance of the enamel finish.

Environmental Impact and Sustainability

Enamel on steel offers better recyclability due to steel's widespread recycling infrastructure, making it a more sustainable choice compared to enamel on copper, which has limited recycling programs. The extraction and processing of copper typically involve higher energy consumption and environmental degradation, increasing its overall carbon footprint. Steel's durability and recyclability contribute to lower environmental impact and support circular economy principles in enamel-coated products.

Choosing Between Enamel on Steel and Enamel on Copper

Choosing between enamel on steel and enamel on copper depends on factors such as durability, heat conductivity, and cost. Enamel on steel offers superior strength and resistance to impact, making it ideal for heavy-duty applications, while enamel on copper provides excellent thermal conductivity and is preferred for cookware requiring even heat distribution. Budget constraints and intended use influence the decision, with steel-enamel products typically more affordable and copper-enamel items favored for high-performance cooking.

Enamel On Steel vs Enamel On Copper Infographic

materialdif.com

materialdif.com