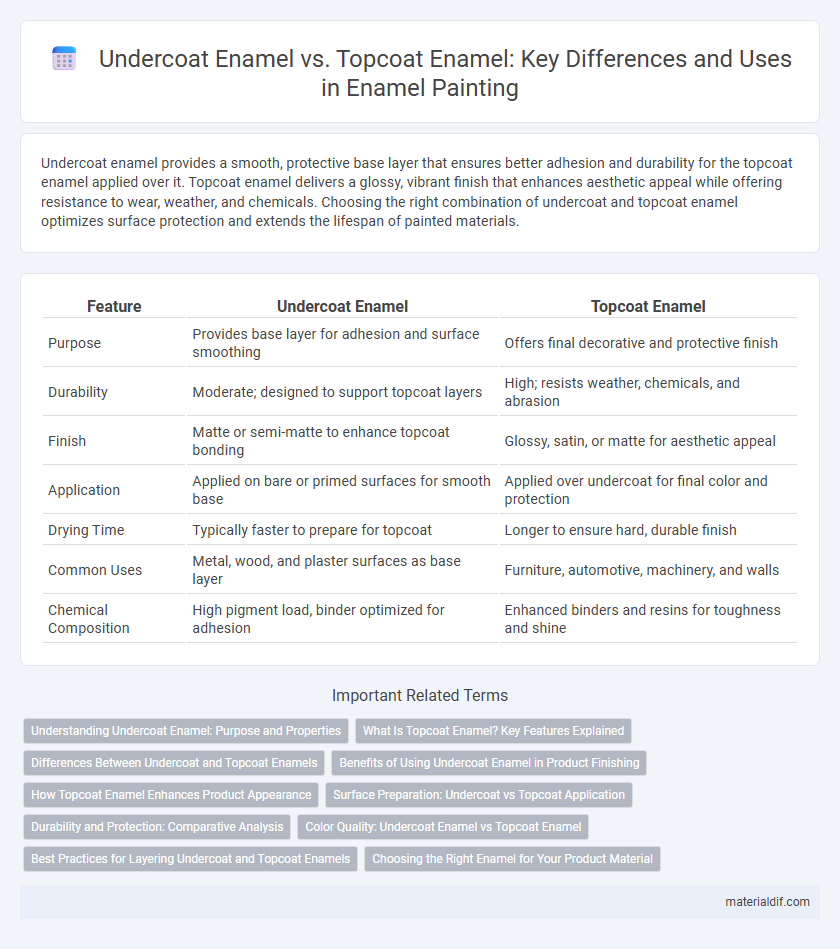

Undercoat enamel provides a smooth, protective base layer that ensures better adhesion and durability for the topcoat enamel applied over it. Topcoat enamel delivers a glossy, vibrant finish that enhances aesthetic appeal while offering resistance to wear, weather, and chemicals. Choosing the right combination of undercoat and topcoat enamel optimizes surface protection and extends the lifespan of painted materials.

Table of Comparison

| Feature | Undercoat Enamel | Topcoat Enamel |

|---|---|---|

| Purpose | Provides base layer for adhesion and surface smoothing | Offers final decorative and protective finish |

| Durability | Moderate; designed to support topcoat layers | High; resists weather, chemicals, and abrasion |

| Finish | Matte or semi-matte to enhance topcoat bonding | Glossy, satin, or matte for aesthetic appeal |

| Application | Applied on bare or primed surfaces for smooth base | Applied over undercoat for final color and protection |

| Drying Time | Typically faster to prepare for topcoat | Longer to ensure hard, durable finish |

| Common Uses | Metal, wood, and plaster surfaces as base layer | Furniture, automotive, machinery, and walls |

| Chemical Composition | High pigment load, binder optimized for adhesion | Enhanced binders and resins for toughness and shine |

Understanding Undercoat Enamel: Purpose and Properties

Undercoat enamel serves as a crucial base layer, providing excellent adhesion and enhancing the durability of the topcoat enamel by creating a smooth, uniform surface. It typically features properties such as fast drying time, good fill power, and resistance to moisture and corrosion, ensuring long-lasting protection for various surfaces. This enamel undercoat reduces imperfections and promotes better coverage, leading to an even, professional finish in painting projects.

What Is Topcoat Enamel? Key Features Explained

Topcoat enamel is a durable, glossy paint layer designed to provide a smooth, protective finish on surfaces. Key features include high resistance to scratches, moisture, and UV rays, ensuring long-lasting color retention and surface protection. Unlike undercoat enamel, which promotes adhesion and surface uniformity, topcoat enamel enhances aesthetic appeal while sealing and safeguarding the underlying layers.

Differences Between Undercoat and Topcoat Enamels

Undercoat enamel functions primarily as a primer, offering excellent adhesion and sealing properties to prepare surfaces for subsequent layers. Topcoat enamel provides the final decorative finish with enhanced durability, gloss, and resistance to environmental factors. The key differences lie in their composition: undercoat enamel contains more fillers and has a duller finish, while topcoat enamel features higher pigment concentration and a smooth, glossy appearance.

Benefits of Using Undercoat Enamel in Product Finishing

Undercoat enamel provides a smooth, durable base layer that enhances adhesion for subsequent topcoat enamel applications, preventing peeling and chipping. Its sealing properties protect against moisture and corrosion, extending the longevity of the finished product. Utilizing undercoat enamel improves overall finish quality by creating an even surface that optimizes color vibrancy and uniformity in the topcoat.

How Topcoat Enamel Enhances Product Appearance

Topcoat enamel significantly enhances product appearance by providing a smooth, glossy finish that highlights color depth and surface details. Its protective properties shield the undercoat enamel from environmental damage, preventing fading and ensuring long-lasting vibrancy. This layer also improves resistance to scratches and chemicals, maintaining the aesthetic quality of painted surfaces over time.

Surface Preparation: Undercoat vs Topcoat Application

Undercoat enamel requires meticulous surface preparation, including thorough cleaning, sanding, and priming to ensure adhesion and durability, as it forms the foundation layer. Topcoat enamel demands a smoother surface, often sanded lightly after the undercoat dries, to achieve a glossy, even finish and maximize protective qualities. Proper surface preparation between undercoat and topcoat applications significantly influences paint longevity and resistance to chipping, peeling, and environmental damage.

Durability and Protection: Comparative Analysis

Undercoat enamel provides a robust base layer designed to enhance adhesion and corrosion resistance, extending the lifespan of the paint system. Topcoat enamel offers superior durability against environmental factors such as UV exposure, moisture, and abrasion, serving as the primary shield for surfaces. Comparing both, undercoat enamel ensures foundational protection and bonding, while topcoat enamel delivers enhanced surface durability and aesthetic longevity.

Color Quality: Undercoat Enamel vs Topcoat Enamel

Undercoat enamel is formulated primarily for hiding imperfections and promoting adhesion, offering a consistent base but limited color vibrancy. Topcoat enamel provides the final color layer with enhanced pigment concentration, delivering superior gloss, durability, and true-to-swatch color accuracy. Choosing high-quality topcoat enamel ensures optimal color brilliance and long-lasting finish compared to the muted tone of undercoat enamel.

Best Practices for Layering Undercoat and Topcoat Enamels

Applying undercoat enamel ensures a smooth, adhesive base that enhances durability and prevents surface imperfections. Use topcoat enamel for a glossy, protective finish that resists chipping and UV damage, improving overall aesthetic appeal. Allow each enamel layer to dry completely before applying the next to maximize adhesion and longevity of the paint job.

Choosing the Right Enamel for Your Product Material

Undercoat enamel provides excellent adhesion and corrosion resistance, making it ideal for prepping metal surfaces and enhancing durability. Topcoat enamel offers superior color depth and gloss, perfect for achieving a polished finish on wood, metal, or plastic products. Selecting the right enamel involves considering the substrate, desired finish, and environmental exposure to ensure optimal performance and longevity.

Undercoat enamel vs Topcoat enamel Infographic

materialdif.com

materialdif.com