Baked enamel provides a durable, glossy finish achieved through high-temperature curing, making it ideal for heavy-use items and long-lasting protection. Spray enamel offers convenience and ease of application with fast drying times but may lack the same level of hardness and resistance as baked enamel. Choosing between baked and spray enamel depends on the required durability and the specific surface treatment demands.

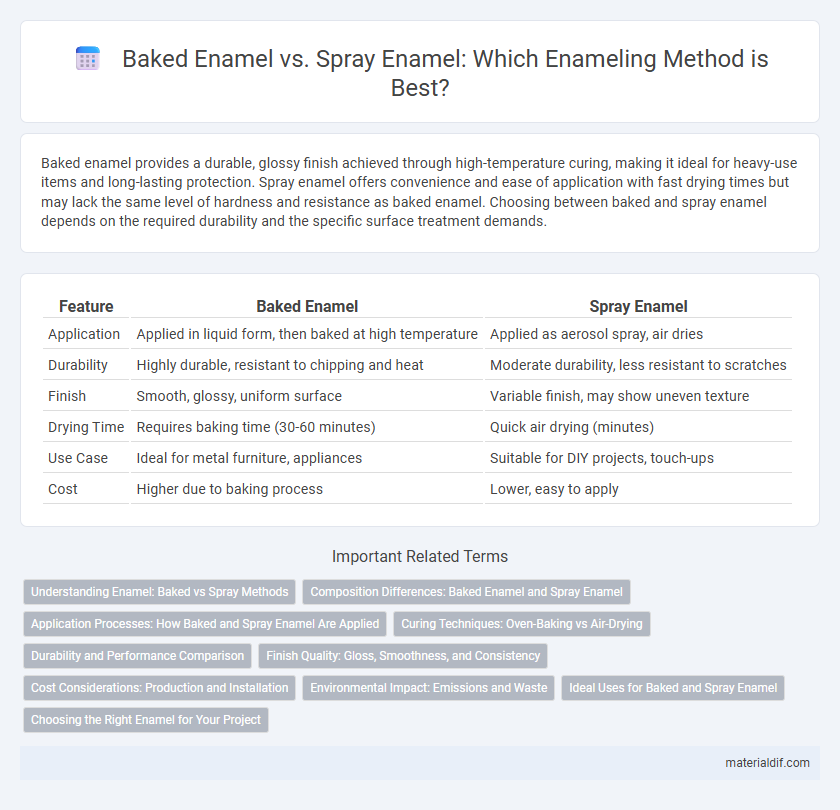

Table of Comparison

| Feature | Baked Enamel | Spray Enamel |

|---|---|---|

| Application | Applied in liquid form, then baked at high temperature | Applied as aerosol spray, air dries |

| Durability | Highly durable, resistant to chipping and heat | Moderate durability, less resistant to scratches |

| Finish | Smooth, glossy, uniform surface | Variable finish, may show uneven texture |

| Drying Time | Requires baking time (30-60 minutes) | Quick air drying (minutes) |

| Use Case | Ideal for metal furniture, appliances | Suitable for DIY projects, touch-ups |

| Cost | Higher due to baking process | Lower, easy to apply |

Understanding Enamel: Baked vs Spray Methods

Baked enamel involves applying a powdered or liquid coating that is cured at high temperatures, resulting in a durable, glossy, and chip-resistant finish ideal for metal surfaces like appliances and automotive parts. Spray enamel, on the other hand, uses aerosol or spray gun application, providing quicker and more versatile coverage, but with a less durable and potentially uneven finish compared to baked enamel. Choosing between baked and spray enamel depends on factors such as durability requirements, surface type, and the desired finish's longevity and appearance.

Composition Differences: Baked Enamel and Spray Enamel

Baked enamel consists of finely ground glass particles mixed with pigments and solvents, which fuse into a hard, durable coating when heated to high temperatures, enhancing chemical resistance and longevity. Spray enamel typically contains synthetic resins and pigments suspended in volatile solvents that evaporate upon application, forming a quick-drying but less durable surface layer. The molecular bonding in baked enamel results in superior adhesion and hardness compared to the more flexible but softer finish of spray enamel.

Application Processes: How Baked and Spray Enamel Are Applied

Baked enamel involves applying a liquid coating to a surface, followed by curing in a high-temperature oven to achieve a hard, durable finish resistant to chips and corrosion. Spray enamel is applied using an aerosol or spray gun, offering quick coverage and ease of use, but it typically requires multiple thin layers and air drying, resulting in a less durable finish compared to baked enamel. The choice between baked and spray enamel depends on the desired durability, application environment, and the complexity of the object's shape.

Curing Techniques: Oven-Baking vs Air-Drying

Baked enamel requires oven-baking at temperatures typically between 250degF and 400degF, which ensures a durable, smooth, and glossy finish by chemically fusing the enamel to the substrate. Spray enamel relies on air-drying or ambient curing, resulting in a less resilient coating that may be more prone to chipping and uneven surfaces. The oven-baking technique significantly enhances adhesion and hardness compared to the slower, less controlled air-drying process used for spray enamels.

Durability and Performance Comparison

Baked enamel outperforms spray enamel in durability due to its hardened, heat-cured finish that resists chipping, scratching, and fading over time. Spray enamel offers quicker application and good coverage but tends to be less resilient under harsh environmental conditions. The high-temperature curing process of baked enamel results in superior adhesion and a longer-lasting, more robust protective coating compared to the softer, more flexible layer formed by spray enamel.

Finish Quality: Gloss, Smoothness, and Consistency

Baked enamel typically delivers a superior finish quality characterized by higher gloss, enhanced smoothness, and consistent coating thickness due to the curing process that fuses the enamel to the surface. Spray enamel offers convenience and faster application but may result in a less uniform gloss and minor texture variations caused by overspray and drying conditions. The curing temperature and time in baked enamel processes play a critical role in achieving an even, durable, and glossy finish unmatched by spray enamel techniques.

Cost Considerations: Production and Installation

Baked enamel generally incurs higher production costs due to the energy-intensive curing process and specialized equipment required for high-temperature baking. Spray enamel offers lower installation expenses since it can be applied quickly without the need for ovens, reducing labor and time. Businesses often weigh the durability and finish quality of baked enamel against the budget-friendly, flexible application of spray enamel when considering total project costs.

Environmental Impact: Emissions and Waste

Baked enamel typically emits fewer volatile organic compounds (VOCs) during curing due to controlled industrial ovens, reducing air pollution compared to spray enamel, which often releases higher VOC levels during application. Spray enamel generates more overspray waste and hazardous aerosols, increasing environmental contamination risks, whereas baked enamel's process minimizes particulate emissions and material waste. Proper ventilation and recovery systems in baked enamel production significantly lower its overall environmental footprint compared to the more pollutant-intensive spray enamel usage.

Ideal Uses for Baked and Spray Enamel

Baked enamel provides a durable, high-gloss finish ideal for metal surfaces exposed to heat and wear, such as automotive parts and kitchen appliances. Spray enamel is best suited for quick touch-ups and projects requiring easy application on irregular surfaces like furniture, art pieces, or DIY crafts. Both types offer corrosion resistance, but baked enamel delivers superior hardness and longevity for industrial use.

Choosing the Right Enamel for Your Project

Baked enamel offers superior durability and a smooth, glossy finish ideal for metal surfaces exposed to high heat or wear, making it perfect for automotive and appliance projects. Spray enamel provides quick application and versatility on various substrates, suited for smaller DIY tasks or touch-ups where convenience is a priority. Selecting between baked and spray enamel depends on your project's durability requirements, surface type, and desired finish quality.

Baked enamel vs spray enamel Infographic

materialdif.com

materialdif.com