Glass enamel offers a durable, smooth finish created by fusing powdered glass to a metal surface at high temperatures, providing excellent resistance to heat and corrosion. Ceramic glaze, applied to pottery or ceramics, forms a glassy coating through firing that enhances aesthetic appeal and waterproofs the item. While both coatings improve surface hardness and appearance, glass enamel is favored for industrial and metal applications, whereas ceramic glaze is primarily used in pottery and tile.

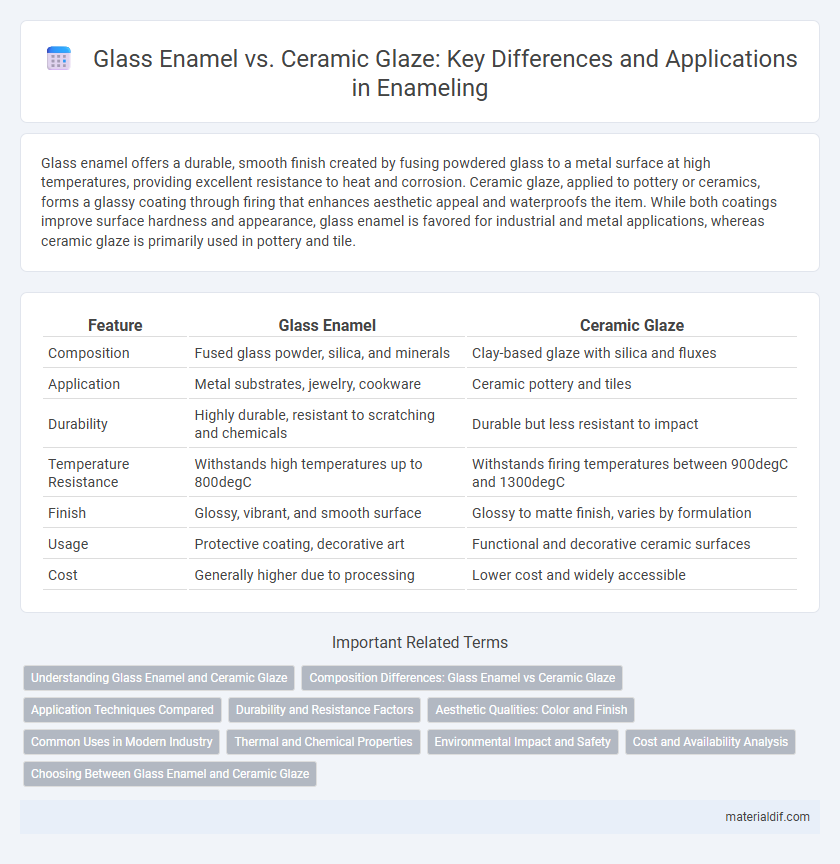

Table of Comparison

| Feature | Glass Enamel | Ceramic Glaze |

|---|---|---|

| Composition | Fused glass powder, silica, and minerals | Clay-based glaze with silica and fluxes |

| Application | Metal substrates, jewelry, cookware | Ceramic pottery and tiles |

| Durability | Highly durable, resistant to scratching and chemicals | Durable but less resistant to impact |

| Temperature Resistance | Withstands high temperatures up to 800degC | Withstands firing temperatures between 900degC and 1300degC |

| Finish | Glossy, vibrant, and smooth surface | Glossy to matte finish, varies by formulation |

| Usage | Protective coating, decorative art | Functional and decorative ceramic surfaces |

| Cost | Generally higher due to processing | Lower cost and widely accessible |

Understanding Glass Enamel and Ceramic Glaze

Glass enamel consists of finely ground glass powders fused onto metal substrates at high temperatures, creating a durable, glossy surface often used in cookware and art. Ceramic glaze, a glassy coating fused onto ceramic bodies, enhances both aesthetics and functionality by providing a waterproof, smooth finish. Differentiating factors include the substrate compatibility, firing temperatures, and specific applications where glass enamel primarily suits metals, whereas ceramic glaze is integral to pottery and ceramic wares.

Composition Differences: Glass Enamel vs Ceramic Glaze

Glass enamel consists primarily of powdered glass fused to a surface through high-temperature firing, creating a smooth, durable coating with strong resistance to corrosion and thermal shock. Ceramic glaze, composed mainly of silica, fluxes, and alumina, undergoes vitrification during firing, resulting in a hard, often glossy layer that enhances both aesthetics and waterproofing. The key compositional distinction lies in glass enamel's dominant glass matrix compared to ceramic glaze's mixture of mineral oxides tailored for specific functional and decorative properties.

Application Techniques Compared

Glass enamel application techniques primarily involve wet spraying and dipping, allowing for smooth, uniform coatings ideal for metal substrates. Ceramic glaze is typically applied through brushing, spraying, or pouring onto pottery before firing in a kiln, resulting in durable, vitrified finishes. Differences in thermal expansion and firing temperatures dictate the choice of method, with glass enamel requiring lower-temperature firing than ceramic glaze.

Durability and Resistance Factors

Glass enamel offers superior durability and resistance to scratches, chemicals, and heat compared to ceramic glaze, making it ideal for industrial applications. Ceramic glaze, while aesthetically versatile, tends to be more susceptible to chipping and wear under heavy use or thermal stress. The compact, non-porous nature of glass enamel enhances its longevity and protective qualities in harsh environments.

Aesthetic Qualities: Color and Finish

Glass enamel offers vibrant, glossy finishes with a smooth, reflective surface that enhances color brightness and depth, making it ideal for decorative applications requiring high shine. Ceramic glaze provides a more varied texture range, from matte to glossy, with subtle color variations due to its porous material base, resulting in unique, natural finishes favored in pottery and tile art. Both materials offer durable coloration, but glass enamel excels in uniformity and intensity of color, while ceramic glaze emphasizes tactile variation and artisanal character.

Common Uses in Modern Industry

Glass enamel and ceramic glaze are widely applied in modern industry for surface protection and decorative purposes, with glass enamel commonly used in cookware, appliances, and architectural panels due to its smooth, durable, and heat-resistant finish. Ceramic glaze finds extensive use in sanitaryware, tiles, and pottery, providing a hard, glossy coating that enhances water resistance and aesthetic appeal. Both materials contribute significantly to corrosion resistance and durability in industrial applications, with selection depending on specific thermal and mechanical requirements.

Thermal and Chemical Properties

Glass enamel offers superior thermal shock resistance and durability due to its strong fusion with metal substrates, enabling it to withstand rapid temperature changes without chipping or cracking. Ceramic glaze, while providing excellent chemical resistance and hardness, is more prone to thermal stress and can develop cracks under sudden temperature fluctuations. The chemical inertness of glass enamel makes it ideal for protecting metal surfaces from corrosion, whereas ceramic glaze is better suited for decorative and protective coatings on pottery and tiles that endure less thermal variation.

Environmental Impact and Safety

Glass enamel typically contains silica, soda ash, and metal oxides, which can emit fewer volatile organic compounds (VOCs) during firing compared to some ceramic glazes that may release harmful heavy metals like lead or cadmium. Ceramic glazes often require higher firing temperatures, resulting in greater energy consumption and carbon emissions, whereas glass enamel's lower firing range can reduce environmental impact. Both materials are durable and non-toxic once matured, but glass enamel's composition and lower energy demands generally offer a safer and more eco-friendly option for coating surfaces.

Cost and Availability Analysis

Glass enamel typically incurs a higher cost due to complex manufacturing processes and the use of specialized raw materials, whereas ceramic glaze offers a more budget-friendly option with widespread availability in various forms. The supply chain for ceramic glazes is extensive, allowing easier access and competitive pricing, while glass enamel requires precise firing conditions, limiting its supply and increasing expenses. For large-scale projects or applications demanding cost efficiency, ceramic glaze remains the preferred choice, whereas glass enamel suits niche applications valuing durability and aesthetic vibrancy despite higher costs.

Choosing Between Glass Enamel and Ceramic Glaze

Choosing between glass enamel and ceramic glaze depends on the desired finish and durability; glass enamel offers a glossy, smooth surface with excellent resistance to corrosion and UV fading. Ceramic glaze provides a more textured, matte finish with superior heat resistance and a wider range of color options. Consider the application environment, with glass enamel ideal for metal surfaces and outdoor use, while ceramic glaze suits pottery and high-temperature ceramics.

Glass Enamel vs Ceramic Glaze Infographic

materialdif.com

materialdif.com