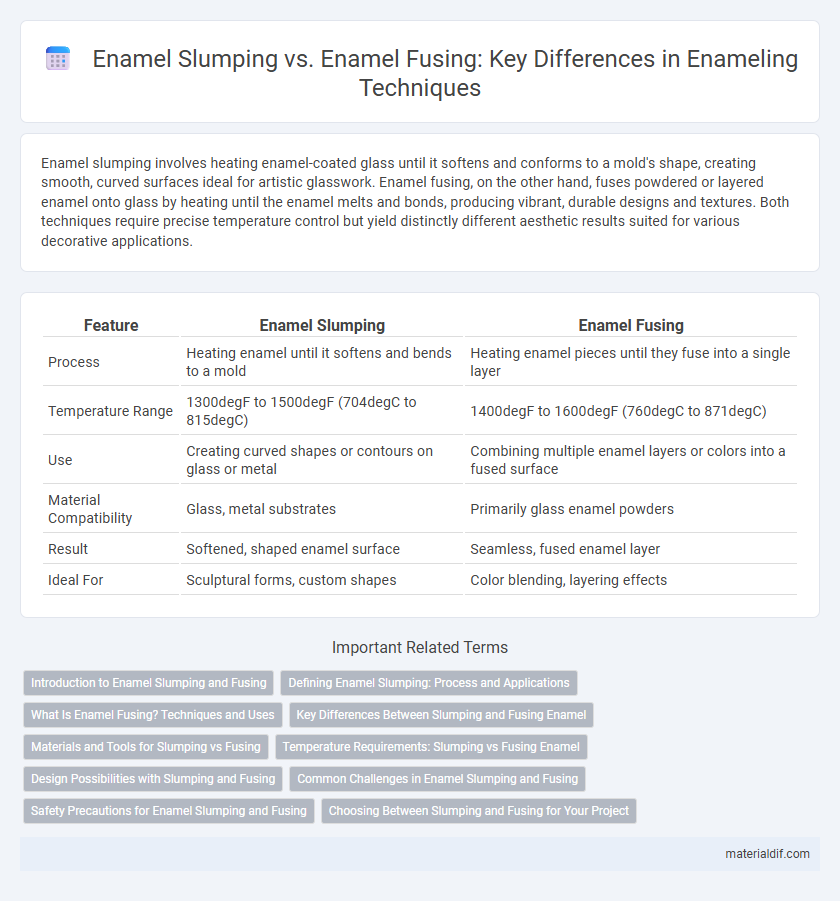

Enamel slumping involves heating enamel-coated glass until it softens and conforms to a mold's shape, creating smooth, curved surfaces ideal for artistic glasswork. Enamel fusing, on the other hand, fuses powdered or layered enamel onto glass by heating until the enamel melts and bonds, producing vibrant, durable designs and textures. Both techniques require precise temperature control but yield distinctly different aesthetic results suited for various decorative applications.

Table of Comparison

| Feature | Enamel Slumping | Enamel Fusing |

|---|---|---|

| Process | Heating enamel until it softens and bends to a mold | Heating enamel pieces until they fuse into a single layer |

| Temperature Range | 1300degF to 1500degF (704degC to 815degC) | 1400degF to 1600degF (760degC to 871degC) |

| Use | Creating curved shapes or contours on glass or metal | Combining multiple enamel layers or colors into a fused surface |

| Material Compatibility | Glass, metal substrates | Primarily glass enamel powders |

| Result | Softened, shaped enamel surface | Seamless, fused enamel layer |

| Ideal For | Sculptural forms, custom shapes | Color blending, layering effects |

Introduction to Enamel Slumping and Fusing

Enamel slumping involves heating glass enamel to a temperature where it softens and conforms to the shape of a mold, enhancing texture and three-dimensional effects in glass art. Enamel fusing, by contrast, requires melting enamel powders or sheets until they bond smoothly on a glass surface, creating a solid, fused layer with vibrant color and design. Both techniques require precise temperature control to achieve desired structural and aesthetic outcomes in glasswork.

Defining Enamel Slumping: Process and Applications

Enamel slumping is a process where powdered glass enamel is applied to a metal or glass surface and then heated until it softens and molds to the substrate without fully melting, creating a textured or contoured finish. This technique is commonly used in artistic glasswork and jewelry making to achieve three-dimensional designs and raised effects. Applications of enamel slumping include decorative panels, custom jewelry pieces, and ceramic art forms that require controlled shaping of the enamel surface.

What Is Enamel Fusing? Techniques and Uses

Enamel fusing is a process where powdered glass or enamel is heated until it melts and bonds to a metal or glass surface, creating a smooth, durable coating. Techniques include kiln firing, where the enamel is applied and fired at high temperatures, and torch fusing, which uses a direct flame for localized heating. Enamel fusing is commonly used in jewelry making, decorative art, and industrial applications for its vibrant color retention and resistance to corrosion.

Key Differences Between Slumping and Fusing Enamel

Enamel slumping involves heating enamel-coated glass just enough to soften it and conform to a mold's shape without melting the glass itself, whereas enamel fusing requires higher temperatures that cause multiple enamel layers or pieces to melt and fuse into a single, smooth surface. Slumping is primarily used to achieve dimensional shaping, such as bowls or curved panels, while fusing focuses on creating decorative, layered designs or sealed surfaces. The key temperature difference generally ranges from about 1300degF (704degC) for slumping to 1450degF (788degC) or higher for fusing, impacting the enamel's texture and structural integrity.

Materials and Tools for Slumping vs Fusing

Enamel slumping requires a flexible kiln shelf, a ceramic or stainless steel mold, and powdered or sifted enamel to achieve gradual shaping using controlled heat. Enamel fusing demands a sturdy kiln shelf, glass sheets or pre-cut enamel pieces, and precise layering to permanently bond enamel at higher temperatures. Tools such as spatulas and firing gloves are essential for both processes, but slumping emphasizes mold support, while fusing focuses on clean, flat surfaces for optimal glass adhesion.

Temperature Requirements: Slumping vs Fusing Enamel

Enamel slumping typically occurs at lower temperatures, around 1300degF to 1500degF, allowing the glass to soften and conform to molds without fully melting. In contrast, enamel fusing requires higher temperatures, generally between 1450degF and 1600degF, to fully melt the enamel particles and create a smooth, fused surface. Precise temperature control is crucial in both techniques to achieve desired texture and durability while avoiding defects like cracking or crazing.

Design Possibilities with Slumping and Fusing

Enamel slumping offers dynamic design possibilities by allowing glass to be softened and shaped over molds, enabling three-dimensional textures and curved forms that enhance the tactile and visual appeal of the piece. Enamel fusing provides the ability to layer multiple enamel colors and textures on flat surfaces, creating intricate, smooth, and vibrant designs with controlled blending and sharp detailing. Combining slumping and fusing techniques expands creative potential, facilitating versatile effects ranging from sculptural shapes to vivid, complex surface patterns ideal for both artistic and functional enamel works.

Common Challenges in Enamel Slumping and Fusing

Enamel slumping and fusing both present challenges related to temperature control and compatibility of materials, with slumping requiring precise heating to avoid warping or tearing of the enamel surface. Fusing often faces difficulties in achieving complete bonding without bubbles or discoloration, as variations in kiln temperature and enamel thickness impact the final finish. Both techniques demand careful management of cooling rates to prevent cracking and ensure structural integrity.

Safety Precautions for Enamel Slumping and Fusing

Enamel slumping and fusing require strict safety precautions to prevent exposure to high temperatures and toxic fumes. Use heat-resistant gloves, safety goggles, and proper ventilation systems when handling kilns to avoid burns and inhalation hazards. Ensuring a well-ventilated workspace and following manufacturer guidelines for kiln operation reduces risks associated with enamel firing processes.

Choosing Between Slumping and Fusing for Your Project

Choosing between enamel slumping and enamel fusing depends on the desired texture and structural outcome of your glass project. Enamel slumping softens the glass enamel in a kiln to create curved, molded shapes, ideal for decorative bowls or plates, whereas enamel fusing melts powdered or sheet enamel into a smooth, glassy surface, perfect for vibrant, flat designs with strong adherent qualities. For projects emphasizing three-dimensional form and gentle curves, slumping offers flexibility, while fusing excels in achieving intense color blending and durable, glossy finishes.

Enamel Slumping vs Enamel Fusing Infographic

materialdif.com

materialdif.com