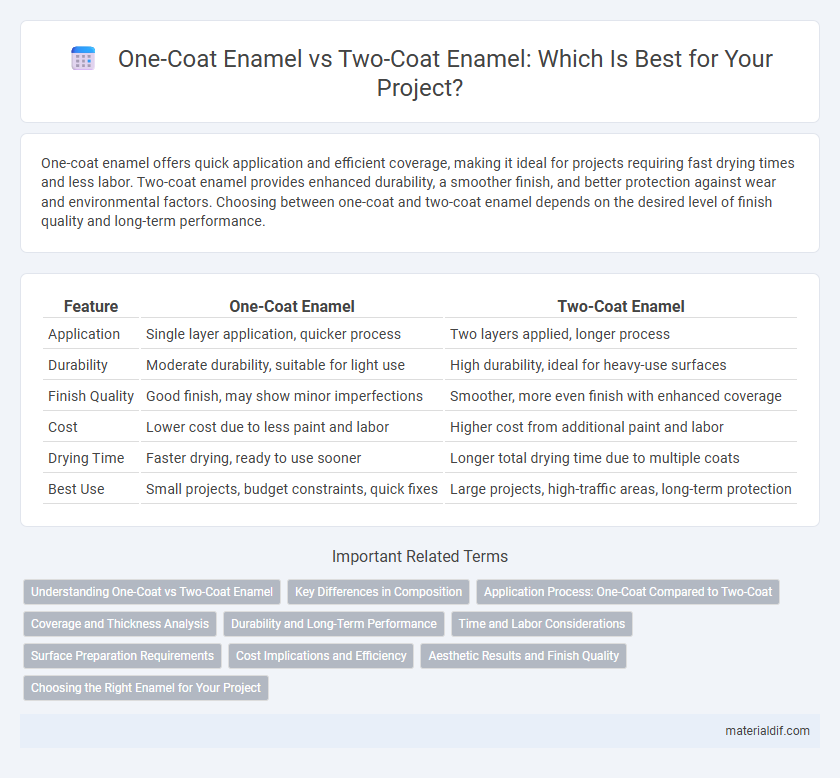

One-coat enamel offers quick application and efficient coverage, making it ideal for projects requiring fast drying times and less labor. Two-coat enamel provides enhanced durability, a smoother finish, and better protection against wear and environmental factors. Choosing between one-coat and two-coat enamel depends on the desired level of finish quality and long-term performance.

Table of Comparison

| Feature | One-Coat Enamel | Two-Coat Enamel |

|---|---|---|

| Application | Single layer application, quicker process | Two layers applied, longer process |

| Durability | Moderate durability, suitable for light use | High durability, ideal for heavy-use surfaces |

| Finish Quality | Good finish, may show minor imperfections | Smoother, more even finish with enhanced coverage |

| Cost | Lower cost due to less paint and labor | Higher cost from additional paint and labor |

| Drying Time | Faster drying, ready to use sooner | Longer total drying time due to multiple coats |

| Best Use | Small projects, budget constraints, quick fixes | Large projects, high-traffic areas, long-term protection |

Understanding One-Coat vs Two-Coat Enamel

One-coat enamel offers a quicker application process with sufficient coverage for minor repairs and projects, saving time and materials. Two-coat enamel provides enhanced durability and a richer finish, ideal for high-traffic areas or surfaces requiring long-term protection. Understanding the differences in drying time, coverage, and finish quality helps determine the appropriate enamel type for specific needs.

Key Differences in Composition

One-coat enamel typically contains a higher concentration of pigments and binders to provide sufficient coverage and durability in a single application, while two-coat enamel uses a base layer with less pigment followed by a more pigmented topcoat for enhanced finish and protection. The composition of one-coat enamel emphasizes faster drying times and thicker viscosity to achieve opacity quickly, whereas two-coat enamel formulations balance adhesion and flexibility between layers for improved long-term performance. Selective use of additives in both types affects drying speed, gloss retention, and resistance to environmental factors.

Application Process: One-Coat Compared to Two-Coat

One-coat enamel offers a streamlined application process, requiring only a single layer to achieve coverage, which significantly reduces drying time and labor costs. Two-coat enamel involves applying a base coat followed by a topcoat, enhancing durability and color depth but doubling the application time and effort. This difference makes one-coat enamel ideal for quick projects, while two-coat enamel provides superior protection and finish quality for long-term performance.

Coverage and Thickness Analysis

One-coat enamel provides sufficient coverage for light to moderate surfaces, typically requiring a single application with a thickness of about 1.5 to 2 mils to achieve uniform color and gloss. Two-coat enamel enhances durability and depth, offering a combined thickness of approximately 3 to 4 mils, which improves resistance to wear and provides superior coverage on darker or uneven substrates. Coverage efficiency varies with paint formulation, surface texture, and application method, where two-coat systems generally ensure better opacity and a more consistent finish compared to one-coat options.

Durability and Long-Term Performance

One-coat enamel provides a quick and convenient application but generally offers less durability and long-term protection compared to two-coat enamel. Two-coat enamel creates a thicker, more resilient barrier that enhances resistance to chipping, fading, and environmental wear over time. This increased thickness contributes to superior performance in high-traffic or exposed areas, extending the lifespan of the finish.

Time and Labor Considerations

One-coat enamel significantly reduces application time and labor costs by eliminating the need for multiple drying and recoating stages. Two-coat enamel requires additional preparation and curing periods, increasing overall project duration and workforce hours. Choosing one-coat enamel optimizes efficiency without sacrificing durability when applied correctly.

Surface Preparation Requirements

One-coat enamel requires minimal surface preparation, making it ideal for quick projects and surfaces in good condition, as it adheres well to clean, dry surfaces with little sanding. Two-coat enamel demands more thorough surface preparation, including sanding, priming, and cleaning to ensure optimal adhesion and durability between layers. Proper surface preparation enhances the longevity and finish quality of both types but is more critical for two-coat enamel applications.

Cost Implications and Efficiency

One-coat enamel reduces labor costs and application time by providing sufficient coverage in a single layer, making it a cost-effective choice for budget-conscious projects. Two-coat enamel enhances durability and color depth, which can decrease long-term maintenance expenses despite higher initial material and labor costs. Efficiency depends on project requirements, with one-coat enamel suited for quick, economical finishes, while two-coat enamel ensures superior protection and aesthetic quality.

Aesthetic Results and Finish Quality

One-coat enamel provides a quicker application with a decent finish but often lacks the depth and uniformity seen in two-coat enamel systems. Two-coat enamel enhances aesthetic results by offering improved opacity, smoother texture, and richer color saturation, leading to a more durable and visually appealing surface. The additional layer in two-coat enamel also increases resistance to chipping and environmental wear, resulting in a higher quality finish over time.

Choosing the Right Enamel for Your Project

One-coat enamel offers faster application and sufficient coverage for small or lightly used surfaces, ideal for quick touch-ups or furniture with minimal wear. Two-coat enamel provides enhanced durability and a smoother, more uniform finish, making it better suited for high-traffic areas and surfaces requiring long-lasting protection. Selecting the right enamel depends on project scale, surface condition, and desired longevity to ensure optimal performance and aesthetic appeal.

One-coat enamel vs two-coat enamel Infographic

materialdif.com

materialdif.com