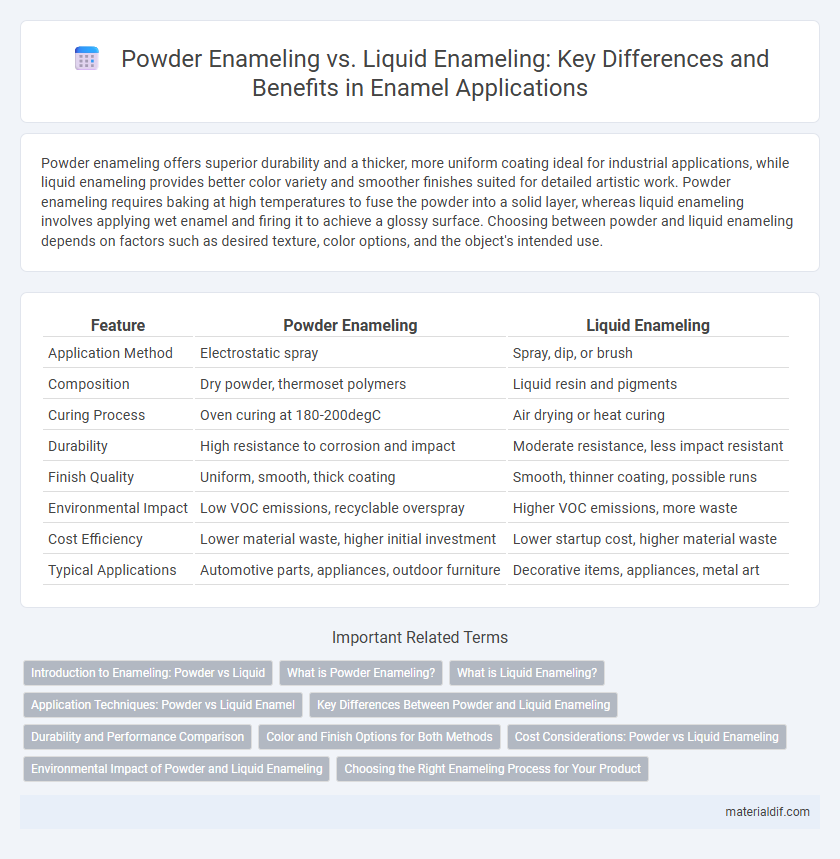

Powder enameling offers superior durability and a thicker, more uniform coating ideal for industrial applications, while liquid enameling provides better color variety and smoother finishes suited for detailed artistic work. Powder enameling requires baking at high temperatures to fuse the powder into a solid layer, whereas liquid enameling involves applying wet enamel and firing it to achieve a glossy surface. Choosing between powder and liquid enameling depends on factors such as desired texture, color options, and the object's intended use.

Table of Comparison

| Feature | Powder Enameling | Liquid Enameling |

|---|---|---|

| Application Method | Electrostatic spray | Spray, dip, or brush |

| Composition | Dry powder, thermoset polymers | Liquid resin and pigments |

| Curing Process | Oven curing at 180-200degC | Air drying or heat curing |

| Durability | High resistance to corrosion and impact | Moderate resistance, less impact resistant |

| Finish Quality | Uniform, smooth, thick coating | Smooth, thinner coating, possible runs |

| Environmental Impact | Low VOC emissions, recyclable overspray | Higher VOC emissions, more waste |

| Cost Efficiency | Lower material waste, higher initial investment | Lower startup cost, higher material waste |

| Typical Applications | Automotive parts, appliances, outdoor furniture | Decorative items, appliances, metal art |

Introduction to Enameling: Powder vs Liquid

Powder enameling involves applying finely ground glass particles that are melted onto a metal surface at high temperatures, creating a durable, uniform coating resistant to corrosion and wear. Liquid enameling uses a spray or brush application of liquid glass suspension, allowing for more intricate designs and faster curing times but may offer less thickness and durability compared to powder. Both methods provide vibrant finishes for metal protection, with powder enameling preferred for heavy-duty industrial use and liquid enameling favored in artistic and detailed work.

What is Powder Enameling?

Powder enameling is a dry finishing process where finely ground glass particles are electrostatically applied to a metal surface and then fused into a smooth, durable coating through high-temperature curing. This technique offers enhanced thickness control, superior abrasion resistance, and environmental benefits due to minimal volatile organic compounds (VOCs) compared to liquid enameling. Widely used in industrial applications, powder enameling provides corrosion protection and vibrant color finishes on appliances, automotive parts, and architectural components.

What is Liquid Enameling?

Liquid enameling is a coating process where finely ground glass particles are suspended in a liquid medium and applied to metal surfaces, creating a smooth, durable, and glossy finish upon firing. This technique allows for more intricate designs and varied colors compared to powder enameling, which uses dry powdered glass fused by heat. Liquid enamel coatings offer superior adhesion on complex shapes and facilitate detailed artistic applications in industrial and decorative sectors.

Application Techniques: Powder vs Liquid Enamel

Powder enameling involves electrostatically applying finely ground powdered glass onto a substrate before baking it in a kiln to create a durable, smooth finish, ideal for thick, even coatings on metal surfaces. Liquid enameling, by contrast, uses a fluid suspension of glass particles suspended in a liquid medium, applied by brushing, spraying, or dipping, allowing for detailed, multi-layered designs with varying thicknesses and colors. The choice between powder and liquid enameling hinges on desired coating uniformity, substrate shape, and aesthetic complexity, with powder enameling favored for industrial, high-durability applications and liquid enameling preferred for artistic, intricate designs.

Key Differences Between Powder and Liquid Enameling

Powder enameling uses finely ground glass particles applied electrostatically and fused at high temperatures, offering superior durability and a thicker coating compared to liquid enameling, which involves spraying or brushing a liquid glass suspension that dries and fuses at lower temperatures. Powder enamel provides enhanced resistance to chipping, chemicals, and UV exposure, making it ideal for heavy-duty applications, while liquid enameling allows for more precise application and better coverage on intricate shapes. The environmental impact of powder enameling is generally lower due to its minimal VOC emissions, whereas liquid enameling requires solvents that can release volatile organic compounds during drying.

Durability and Performance Comparison

Powder enameling offers superior durability due to its thicker, uniform coating that resists chipping, scratching, and corrosion better than liquid enameling. Liquid enameling provides smoother finishes and is ideal for intricate designs but tends to be less resistant to wear and environmental damage over time. For high-performance applications requiring long-lasting protection, powder enamel coatings are generally the preferred choice.

Color and Finish Options for Both Methods

Powder enameling offers a wide range of vibrant, durable color options with a smooth, uniform finish ideal for industrial applications, while liquid enameling provides more nuanced color depth and gloss variations suited for artistic and decorative uses. Both methods enable customized textures and finishes, but powder enameling tends to produce tougher, more consistent surfaces resistant to chipping and fading. Liquid enameling allows for intricate detailing and layered effects, making it preferable for projects requiring fine color gradients and artistry.

Cost Considerations: Powder vs Liquid Enameling

Powder enameling generally offers lower application and operational costs due to reduced waste and faster curing times compared to liquid enameling. Liquid enameling involves higher expenses related to solvent management, drying, and thicker application layers, increasing material consumption. Choosing between powder and liquid enameling depends on the specific project requirements, but cost-efficiency often makes powder enameling the preferred option for large-scale or industrial applications.

Environmental Impact of Powder and Liquid Enameling

Powder enameling generates fewer volatile organic compounds (VOCs), resulting in reduced air pollution and a lower environmental footprint compared to liquid enameling, which relies heavily on solvents that emit harmful VOCs during application and drying. The powder process also enables more efficient material usage with minimal overspray waste, while liquid enameling often leads to higher wastewater generation requiring treatment due to solvent and pigment residues. Energy consumption in powder enameling tends to be lower overall since curing is faster and requires less drying time, further minimizing its ecological impact relative to traditional liquid enameling methods.

Choosing the Right Enameling Process for Your Product

Powder enameling involves applying a dry, powdered glass coating that is fused to metal at high temperatures, offering superior durability and a smooth, uniform finish ideal for heavy-use products. Liquid enameling uses a fluid glass suspension that can be applied more precisely to complex shapes, providing greater versatility and detailed designs but may require longer curing times. Choosing between powder and liquid enameling depends on product specifications such as durability requirements, geometric complexity, and production volume, ensuring optimal finish quality and cost efficiency.

Powder Enameling vs Liquid Enameling Infographic

materialdif.com

materialdif.com