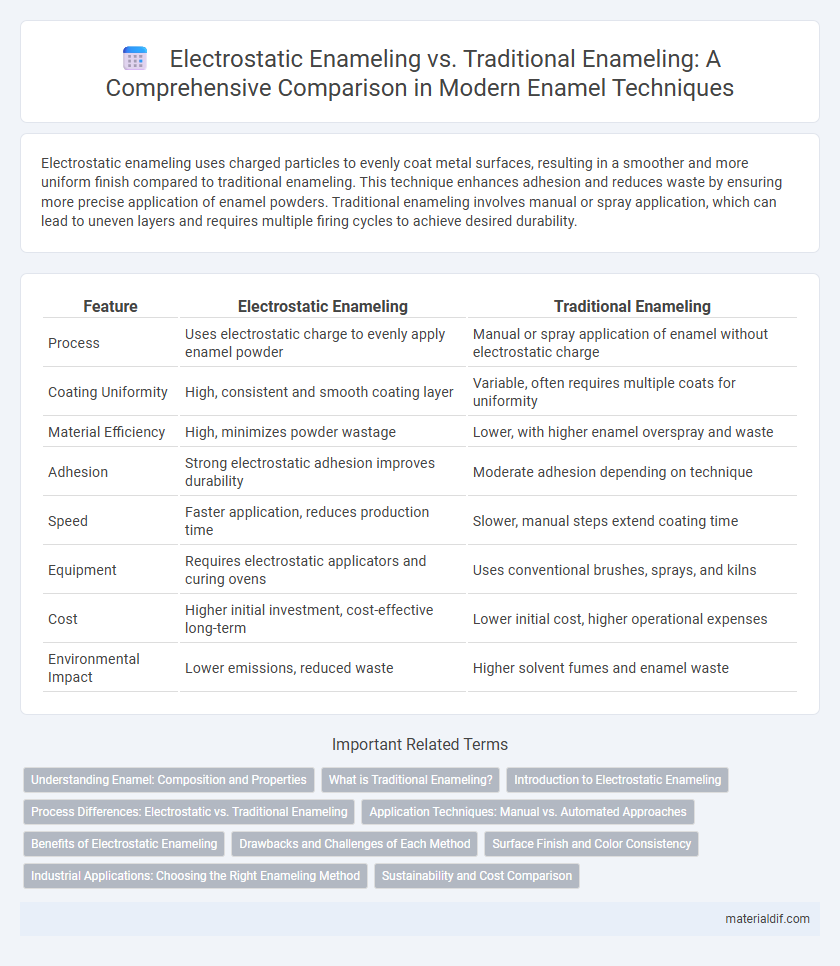

Electrostatic enameling uses charged particles to evenly coat metal surfaces, resulting in a smoother and more uniform finish compared to traditional enameling. This technique enhances adhesion and reduces waste by ensuring more precise application of enamel powders. Traditional enameling involves manual or spray application, which can lead to uneven layers and requires multiple firing cycles to achieve desired durability.

Table of Comparison

| Feature | Electrostatic Enameling | Traditional Enameling |

|---|---|---|

| Process | Uses electrostatic charge to evenly apply enamel powder | Manual or spray application of enamel without electrostatic charge |

| Coating Uniformity | High, consistent and smooth coating layer | Variable, often requires multiple coats for uniformity |

| Material Efficiency | High, minimizes powder wastage | Lower, with higher enamel overspray and waste |

| Adhesion | Strong electrostatic adhesion improves durability | Moderate adhesion depending on technique |

| Speed | Faster application, reduces production time | Slower, manual steps extend coating time |

| Equipment | Requires electrostatic applicators and curing ovens | Uses conventional brushes, sprays, and kilns |

| Cost | Higher initial investment, cost-effective long-term | Lower initial cost, higher operational expenses |

| Environmental Impact | Lower emissions, reduced waste | Higher solvent fumes and enamel waste |

Understanding Enamel: Composition and Properties

Electrostatic enameling enhances the adhesion of enamel powders composed primarily of silica, borates, and metal oxides by using an electrostatic charge to evenly deposit particles on metallic surfaces, creating a smoother and more durable coating. Traditional enameling involves fusing powdered glass to substrates through high-temperature firing, resulting in a robust, corrosion-resistant layer but with less precision in coating thickness. Understanding the chemical composition and thermal stability of enamel materials is crucial for selecting the appropriate enameling method to optimize surface hardness, chemical resistance, and aesthetic quality.

What is Traditional Enameling?

Traditional enameling involves applying powdered glass to a metal surface, typically using a wet process, then firing it at high temperatures to fuse the glass onto the substrate. This method creates a durable, glossy coating that enhances corrosion resistance and aesthetic appeal on metals such as steel or cast iron. Unlike electrostatic enameling, which uses charged particles for more uniform coverage, traditional enameling relies on gravity and manual application techniques.

Introduction to Electrostatic Enameling

Electrostatic enameling utilizes charged enamel particles to achieve uniform coating thickness and enhanced adhesion compared to traditional enameling methods that rely on gravity and manual application. This advanced process reduces material waste and improves finish quality, making it ideal for complex shapes and high-volume production. Electrostatic enameling also offers faster curing times and greater resistance to chipping and corrosion.

Process Differences: Electrostatic vs. Traditional Enameling

Electrostatic enameling utilizes charged enamel particles that are attracted to the grounded metal surface, resulting in a more uniform and efficient coating application. Traditional enameling relies on manual spraying or dipping methods, which often produce thicker, less controlled layers that can lead to uneven coverage. The electrostatic process reduces material waste and curing time while enhancing adhesion and finish quality compared to conventional enameling techniques.

Application Techniques: Manual vs. Automated Approaches

Electrostatic enameling employs automated spray systems that use charged particles to ensure uniform coating and efficient material usage, enhancing precision in industrial applications. Traditional enameling relies primarily on manual dipping or brushing, which allows for greater control on small-scale or artisanal projects but may result in variable thickness and increased labor. Automated electrostatic methods improve consistency and reduce human error, making them ideal for high-volume manufacturing environments.

Benefits of Electrostatic Enameling

Electrostatic enameling provides superior coating adhesion and uniform coverage by using charged particles to evenly distribute enamel onto metal surfaces, reducing material waste and enhancing durability. This method offers faster application times compared to traditional enameling, increasing production efficiency and lowering operational costs. The electrostatic process produces a smoother, more consistent finish with improved resistance to corrosion and wear, extending the lifespan of coated products.

Drawbacks and Challenges of Each Method

Electrostatic enameling faces challenges such as limited coating thickness control and high equipment costs, which can affect precision and overall budget. Traditional enameling struggles with inconsistent coating application and longer curing times, leading to potential surface defects and lower production efficiency. Both methods require careful process optimization to address issues related to adhesion quality and environmental impact.

Surface Finish and Color Consistency

Electrostatic enameling provides a more uniform surface finish by using charged particles that adhere evenly to complex shapes, minimizing imperfections compared to traditional enameling methods. This technique ensures superior color consistency due to controlled particle distribution and reduced material waste, resulting in vibrant, durable coatings. Traditional enameling often suffers from uneven thickness and color variations caused by manual application and gravity effects during firing.

Industrial Applications: Choosing the Right Enameling Method

Electrostatic enameling offers superior coating efficiency and uniformity, making it ideal for complex industrial components and large-scale production lines. Traditional enameling excels in cost-effectiveness for simpler shapes and smaller batches, especially in industries like cookware and decorative items. Evaluating factors such as part geometry, production volume, and desired surface finish is crucial to selecting the most suitable enameling method for efficient industrial applications.

Sustainability and Cost Comparison

Electrostatic enameling offers enhanced sustainability by minimizing material waste and reducing volatile organic compound emissions compared to traditional enameling methods. It achieves cost efficiency through lower energy consumption and faster curing times, which decrease operational expenses. Traditional enameling often requires higher resource inputs and longer processing, leading to elevated costs and environmental impact.

Electrostatic Enameling vs Traditional Enameling Infographic

materialdif.com

materialdif.com