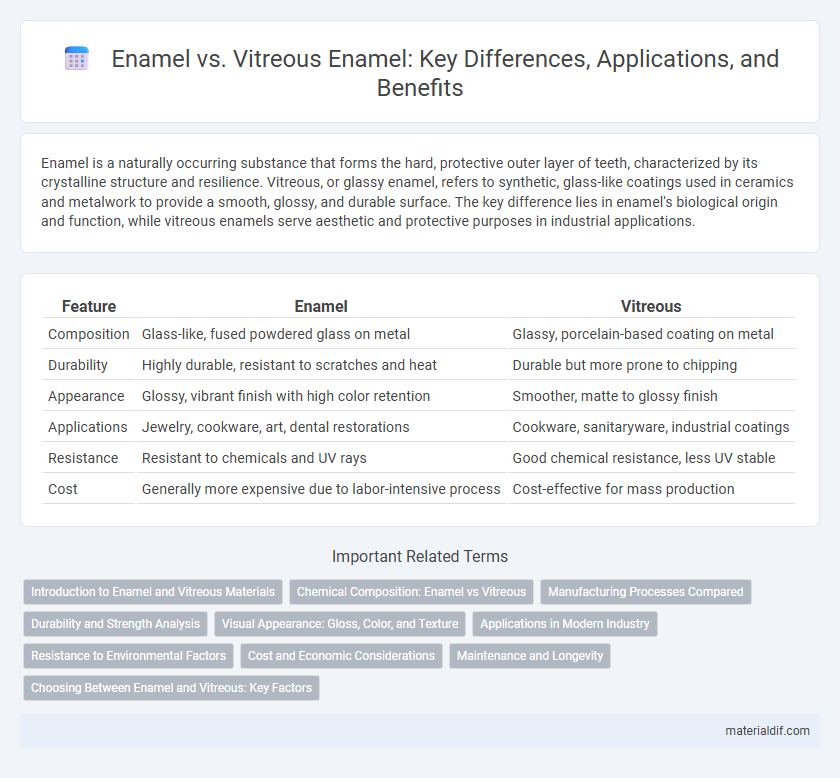

Enamel is a naturally occurring substance that forms the hard, protective outer layer of teeth, characterized by its crystalline structure and resilience. Vitreous, or glassy enamel, refers to synthetic, glass-like coatings used in ceramics and metalwork to provide a smooth, glossy, and durable surface. The key difference lies in enamel's biological origin and function, while vitreous enamels serve aesthetic and protective purposes in industrial applications.

Table of Comparison

| Feature | Enamel | Vitreous |

|---|---|---|

| Composition | Glass-like, fused powdered glass on metal | Glassy, porcelain-based coating on metal |

| Durability | Highly durable, resistant to scratches and heat | Durable but more prone to chipping |

| Appearance | Glossy, vibrant finish with high color retention | Smoother, matte to glossy finish |

| Applications | Jewelry, cookware, art, dental restorations | Cookware, sanitaryware, industrial coatings |

| Resistance | Resistant to chemicals and UV rays | Good chemical resistance, less UV stable |

| Cost | Generally more expensive due to labor-intensive process | Cost-effective for mass production |

Introduction to Enamel and Vitreous Materials

Enamel and vitreous materials both exhibit a glass-like, non-crystalline structure that results in high hardness and chemical resistance. Enamel refers specifically to a durable, glossy coating typically applied to metals through fusing powdered glass at high temperatures, creating a smooth, protective surface. Vitreous materials broadly encompass glass and similar substances formed by rapid cooling of molten silica, characterized by their amorphous structure and brittleness.

Chemical Composition: Enamel vs Vitreous

Enamel primarily consists of hydroxyapatite crystals with a high calcium phosphate content, making it a hard, mineralized tissue. Vitreous, or glass enamel, is composed mainly of silica, boron oxide, and alkali metal oxides, forming a durable, glassy coating through fusion. The chemical composition difference highlights enamel's biological origin and vitreous's synthetic glass matrix structure.

Manufacturing Processes Compared

Enamel and vitreous coatings both involve fusing powdered glass to a substrate, but their manufacturing processes differ in temperature and application techniques. Enamel coatings are typically fired at temperatures between 750 to 850degC, allowing for smooth, durable finishes on metals, while vitreous coatings, often fired at higher temperatures around 850 to 900degC, create a more glass-like, highly resistant surface. The choice between enamel and vitreous manufacturing processes depends on substrate compatibility, desired finish quality, and thermal resistance requirements.

Durability and Strength Analysis

Enamel and vitreous coatings both exhibit high durability, yet enamel offers superior resistance to chipping and thermal shock due to its layered oxide composition. Vitreous coatings, composed primarily of glass, provide excellent hardness and chemical resistance but are more prone to brittle fractures under mechanical stress. Comparative strength analysis confirms enamel's enhanced toughness, making it ideal for heavy-duty applications requiring long-term wear resistance.

Visual Appearance: Gloss, Color, and Texture

Enamel surfaces exhibit a smooth, glossy finish with vibrant, consistent color that enhances visual appeal, while vitreous coatings offer a more glass-like, reflective gloss with deeper translucency and subtle color variations. Enamel typically provides a uniform texture that feels sleek to the touch, whereas vitreous finishes may have a slightly varied surface texture due to the glassy nature of the material. The choice between enamel and vitreous impacts aesthetic outcomes, with enamel delivering bold, vivid coloration and vitreous offering a sophisticated, lustrous depth.

Applications in Modern Industry

Enamel, composed of powdered glass fused onto metal at high temperatures, offers superior chemical resistance and durability compared to vitreous coatings, making it ideal for industrial applications such as cookware, signage, and architectural panels. Vitreous coatings, while similar in composition, often find use in artistic glassware and decorative surfaces due to their enhanced translucency and aesthetic appeal. Modern industries prioritize enamel for heavy-duty applications requiring corrosion resistance and thermal stability, whereas vitreous finishes are favored in sectors emphasizing visual design and light diffusion.

Resistance to Environmental Factors

Enamel offers superior resistance to environmental factors compared to vitreous coatings due to its dense, non-porous surface that effectively repels moisture, chemicals, and temperature fluctuations. While vitreous finishes can be prone to chipping and degradation under harsh conditions, enamel maintains durability and color retention over extended exposure. This makes enamel a preferred choice for applications requiring long-lasting protection against weathering and corrosion.

Cost and Economic Considerations

Enamel coatings generally offer a more cost-effective solution compared to vitreous coatings, making them ideal for budget-sensitive projects. Vitreous enamel provides superior durability and resistance to chemicals and heat, but this enhanced performance often comes with a higher initial investment. Economic considerations should balance upfront costs with long-term maintenance and replacement expenses to determine the most viable option for specific applications.

Maintenance and Longevity

Enamel surfaces demand regular polishing to maintain their glossy finish and resist stains, while vitreous coatings offer superior resistance to wear and require minimal upkeep due to their dense, glass-like composition. Longevity of enamel can be compromised by chips and cracks over time, necessitating prompt repairs, whereas vitreous enamel maintains durability and color vibrancy for decades under normal use. Choosing vitreous enamel ensures a longer lifespan with fewer maintenance interventions compared to traditional enamel finishes.

Choosing Between Enamel and Vitreous: Key Factors

Choosing between enamel and vitreous coatings depends primarily on durability, appearance, and application method. Enamel offers a smooth, glossy finish with high resistance to heat and corrosion, making it ideal for cookware and appliances, while vitreous enamel is fused glass that provides enhanced hardness and a more vibrant color palette suited for artistic and industrial uses. Consider the substrate, environmental exposure, and desired aesthetic when selecting the appropriate coating for optimal performance and longevity.

Enamel vs Vitreous Infographic

materialdif.com

materialdif.com