Glass enamel offers superior durability and resistance to heat and chemicals, making it ideal for industrial and outdoor applications. Resin enamel provides greater flexibility and ease of application, suitable for decorative purposes and less demanding environments. Choosing between glass enamel and resin enamel depends on the required durability, appearance, and application method.

Table of Comparison

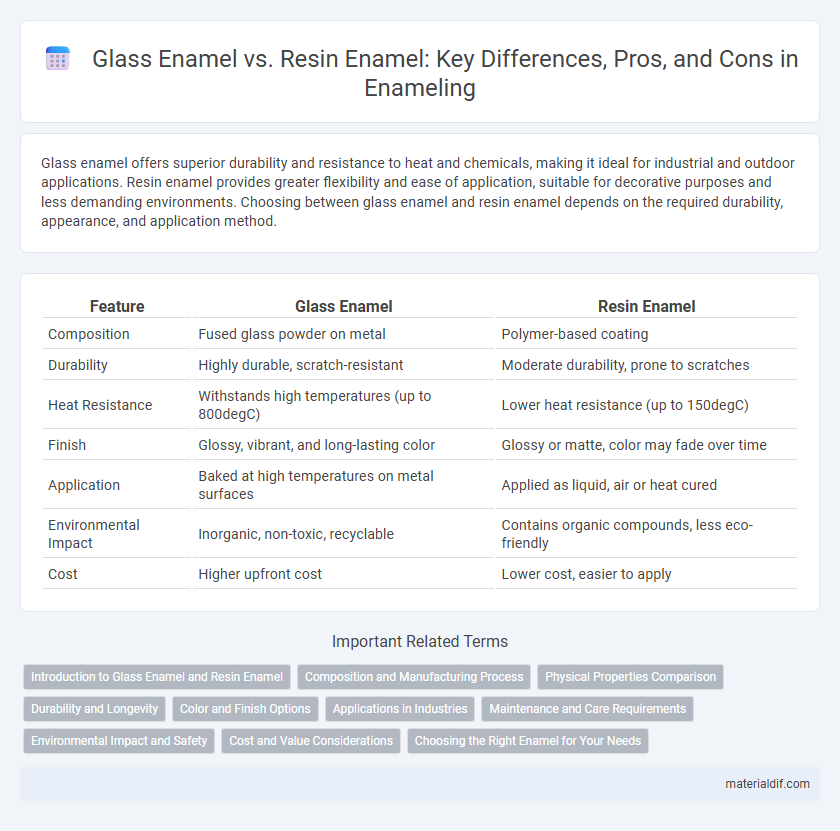

| Feature | Glass Enamel | Resin Enamel |

|---|---|---|

| Composition | Fused glass powder on metal | Polymer-based coating |

| Durability | Highly durable, scratch-resistant | Moderate durability, prone to scratches |

| Heat Resistance | Withstands high temperatures (up to 800degC) | Lower heat resistance (up to 150degC) |

| Finish | Glossy, vibrant, and long-lasting color | Glossy or matte, color may fade over time |

| Application | Baked at high temperatures on metal surfaces | Applied as liquid, air or heat cured |

| Environmental Impact | Inorganic, non-toxic, recyclable | Contains organic compounds, less eco-friendly |

| Cost | Higher upfront cost | Lower cost, easier to apply |

Introduction to Glass Enamel and Resin Enamel

Glass enamel consists of finely ground glass particles fused to a metal surface through high-temperature firing, creating a durable, glossy coating resistant to scratches and chemicals. Resin enamel is a synthetic polymer-based coating applied at room temperature, offering flexibility, faster drying times, and ease of repair but generally lower heat resistance compared to glass enamel. Both types serve protective and decorative purposes, with glass enamel favored for high-durability applications and resin enamel preferred for quicker, cost-effective finishes.

Composition and Manufacturing Process

Glass enamel consists of powdered glass fused to a substrate through high-temperature firing, creating a durable, glossy coating resistant to heat and corrosion. Resin enamel, composed of synthetic polymer resins, is applied as a liquid and cured at lower temperatures, offering flexibility and faster production cycles. The key manufacturing distinction lies in glass enamel's vitrification process versus resin enamel's chemical polymerization, impacting durability and surface characteristics.

Physical Properties Comparison

Glass enamel offers superior hardness and scratch resistance compared to resin enamel, making it ideal for surfaces exposed to heavy wear. Resin enamel provides greater flexibility and impact resistance, which helps prevent cracking or chipping under stress. Temperature tolerance also differs significantly; glass enamel withstands high heat without degradation, while resin enamel may soften or discolor at elevated temperatures.

Durability and Longevity

Glass enamel exhibits superior durability and longevity compared to resin enamel, as it withstands high temperatures, chemical exposure, and physical abrasion without fading or cracking. Unlike resin enamel, which can degrade and yellow over time due to UV exposure and moisture, glass enamel maintains its vibrant appearance and structural integrity for decades. This makes glass enamel ideal for applications requiring long-lasting, weather-resistant coatings such as cookware, signage, and architectural surfaces.

Color and Finish Options

Glass enamel offers a vibrant, glossy finish with exceptional durability and color retention, making it ideal for long-lasting applications that require resistance to wear and heat. Resin enamel provides a wider range of color options, including matte and satin finishes, with faster curing times and greater flexibility on varied surfaces. Choosing between glass and resin enamel depends on whether the priority is high-gloss, hardened surfaces or versatile finishes with diverse color palettes.

Applications in Industries

Glass enamel offers superior durability and chemical resistance, making it ideal for applications in automotive coatings, cookware, and architectural panels. Resin enamel provides flexibility and faster curing times, favored in electronics, appliances, and decorative finishes. Industries select glass enamel for high-temperature and corrosion-resistant needs, while resin enamel suits lightweight, flexible, and cost-effective uses.

Maintenance and Care Requirements

Glass enamel offers superior durability and resistance to scratching, making it low-maintenance and easy to clean with mild detergents. Resin enamel, while providing a glossy finish, requires more frequent touch-ups and delicate handling to prevent chipping and fading over time. Proper care for glass enamel involves simple wiping, whereas resin enamel demands cautious cleaning with non-abrasive materials to maintain its aesthetic integrity.

Environmental Impact and Safety

Glass enamel offers superior environmental benefits with its non-toxic composition, high durability, and recyclability, producing minimal volatile organic compounds (VOCs) during application. Resin enamel, often containing synthetic chemicals and solvents, can release VOCs and pose greater health risks due to potential skin and respiratory irritation. Choosing glass enamel reduces environmental pollution and enhances user safety, making it a more sustainable option for coating applications.

Cost and Value Considerations

Glass enamel offers superior durability and resistance to heat and corrosion, making it a cost-effective choice for long-term applications despite a higher initial price. Resin enamel tends to be more affordable upfront, but it may require more frequent maintenance or replacement due to lower resistance to wear and environmental factors. Evaluating cost versus value, glass enamel often provides better investment returns through extended lifespan and reduced upkeep expenses.

Choosing the Right Enamel for Your Needs

Glass enamel offers superior durability, heat resistance, and a glossy finish ideal for cookware and architectural applications, whereas resin enamel provides flexibility, quicker drying times, and cost-effectiveness suitable for automotive coatings and decorative items. Selecting the right enamel depends on factors like exposure to heat, required surface hardness, and budget constraints. Understanding the specific performance characteristics ensures optimal adhesion, longevity, and aesthetic appeal for the intended use.

Glass Enamel vs Resin Enamel Infographic

materialdif.com

materialdif.com