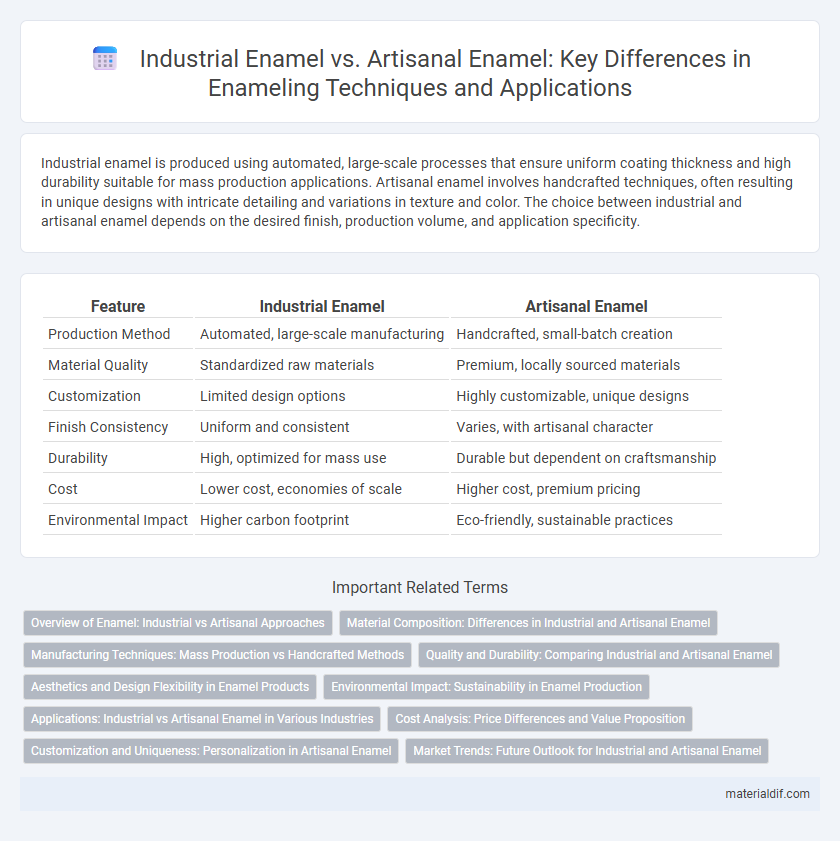

Industrial enamel is produced using automated, large-scale processes that ensure uniform coating thickness and high durability suitable for mass production applications. Artisanal enamel involves handcrafted techniques, often resulting in unique designs with intricate detailing and variations in texture and color. The choice between industrial and artisanal enamel depends on the desired finish, production volume, and application specificity.

Table of Comparison

| Feature | Industrial Enamel | Artisanal Enamel |

|---|---|---|

| Production Method | Automated, large-scale manufacturing | Handcrafted, small-batch creation |

| Material Quality | Standardized raw materials | Premium, locally sourced materials |

| Customization | Limited design options | Highly customizable, unique designs |

| Finish Consistency | Uniform and consistent | Varies, with artisanal character |

| Durability | High, optimized for mass use | Durable but dependent on craftsmanship |

| Cost | Lower cost, economies of scale | Higher cost, premium pricing |

| Environmental Impact | Higher carbon footprint | Eco-friendly, sustainable practices |

Overview of Enamel: Industrial vs Artisanal Approaches

Industrial enamel processes utilize automated techniques and precise temperature controls to produce consistent, durable coatings ideal for mass production in sectors like automotive and cookware. Artisanal enamel focuses on handcrafted methods, emphasizing unique designs and traditional skills, resulting in one-of-a-kind pieces with varied textures and color depth. The choice between industrial and artisanal enamel depends on the desired balance between uniformity, scalability, and artistic expression.

Material Composition: Differences in Industrial and Artisanal Enamel

Industrial enamel typically contains a standardized blend of powdered glass, fluxes, and colorants to ensure consistency and durability across large batches, often incorporating synthetic additives to enhance adhesion and thermal resistance. Artisanal enamel uses more varied and sometimes natural materials, including traditional glass powders and mineral-based pigments, allowing for unique textures and color variations that reflect handcrafted techniques. The material composition in industrial enamel prioritizes uniformity and performance, while artisanal enamel emphasizes customization and aesthetic diversity through its raw ingredient selection.

Manufacturing Techniques: Mass Production vs Handcrafted Methods

Industrial enamel manufacturing relies on mass production techniques such as automated spraying, dipping, and kiln firing, ensuring uniform thickness and consistent quality across large batches. Artisanal enamel is created using handcrafted methods, including meticulous layering and torch firing, allowing for unique textures and intricate designs tailored to each piece. The precision and efficiency of industrial processes contrast with the personalized craftsmanship and variability inherent in artisanal production.

Quality and Durability: Comparing Industrial and Artisanal Enamel

Industrial enamel typically offers higher durability due to controlled manufacturing processes, consistent material composition, and advanced curing techniques that ensure resistance to wear, corrosion, and thermal stress. Artisanal enamel may exhibit unique aesthetic qualities and craftsmanship but often lacks the uniform quality control found in industrial enamel, leading to potential variability in thickness, adhesion, and long-term performance. Quality in industrial enamel is standardized to meet rigorous industry specifications, while artisanal enamel emphasizes artistic expression over mass-produced consistency.

Aesthetics and Design Flexibility in Enamel Products

Industrial enamel offers consistent color quality and smooth finishes ideal for mass-produced items, ensuring uniform appearance across large batches. Artisanal enamel provides greater design flexibility with intricate patterns, vibrant textures, and personalized color blends, enabling unique and expressive aesthetic outcomes. The handcrafted nature of artisanal enamel allows for creative experimentation, making each piece visually distinct compared to the standardized industrial counterparts.

Environmental Impact: Sustainability in Enamel Production

Industrial enamel production often relies on high-energy processes and synthetic chemicals that contribute to greater carbon emissions and hazardous waste. Artisanal enamel techniques typically employ lower temperatures and natural materials, resulting in reduced environmental footprints and enhanced sustainability. Choosing artisanal enamel supports eco-friendly practices by minimizing resource consumption and promoting traditional methods.

Applications: Industrial vs Artisanal Enamel in Various Industries

Industrial enamel is widely used in manufacturing sectors such as automotive, appliances, and aerospace for its durability, heat resistance, and protective coating properties on metals. Artisanal enamel is favored in jewelry, decorative arts, and custom crafts for its aesthetic appeal, intricate designs, and vibrant color range suited to small-scale, handcrafted items. The choice between industrial and artisanal enamel depends on the application requirements, with industrial coatings prioritizing functionality and durability, while artisanal applications emphasize visual artistry and customization.

Cost Analysis: Price Differences and Value Proposition

Industrial enamel production typically offers lower costs due to economies of scale, standardized processes, and bulk raw material purchasing, making it suitable for mass production with consistent quality. Artisanal enamel, characterized by handcrafted techniques and unique designs, commands higher prices reflecting skilled labor, time-intensive methods, and the exclusivity of each piece. Evaluating value proposition involves balancing the affordability and reproducibility of industrial enamel against the craftsmanship, artistic uniqueness, and often bespoke nature of artisanal enamel products.

Customization and Uniqueness: Personalization in Artisanal Enamel

Artisanal enamel offers unparalleled customization and uniqueness through handcrafted techniques that allow for intricate, one-of-a-kind designs tailored to individual preferences, unlike industrial enamel, which relies on standardized production processes limiting personalization. Each piece of artisanal enamel showcases the artist's skill and creative expression, resulting in exclusive items that reflect personal stories or cultural heritage. This personalization in artisanal enamel enhances its value and appeal, making it highly sought after for bespoke jewelry, decorative objects, and collectible art pieces.

Market Trends: Future Outlook for Industrial and Artisanal Enamel

Industrial enamel is experiencing accelerated growth driven by demand in automotive and architecture sectors, leveraging advanced coating technologies for enhanced durability and corrosion resistance. Artisanal enamel maintains a niche market with rising interest fueled by consumer preference for handcrafted, unique designs and sustainable production methods. Market analysts predict that while industrial enamel will dominate due to scalability and innovation, artisanal enamel will expand steadily through targeted marketing and collaborations with luxury brands.

Industrial enamel vs Artisanal enamel Infographic

materialdif.com

materialdif.com