Enameling involves fusing powdered glass to a metal surface at high temperatures, creating a durable and decorative coating that resists corrosion and wear. Electroplating deposits a thin layer of metal onto the surface through an electrical current, enhancing appearance and adding protective properties but often lacking the thickness and vibrant colors of enamel. Both techniques improve metal durability, but enameling offers superior aesthetic versatility and longevity.

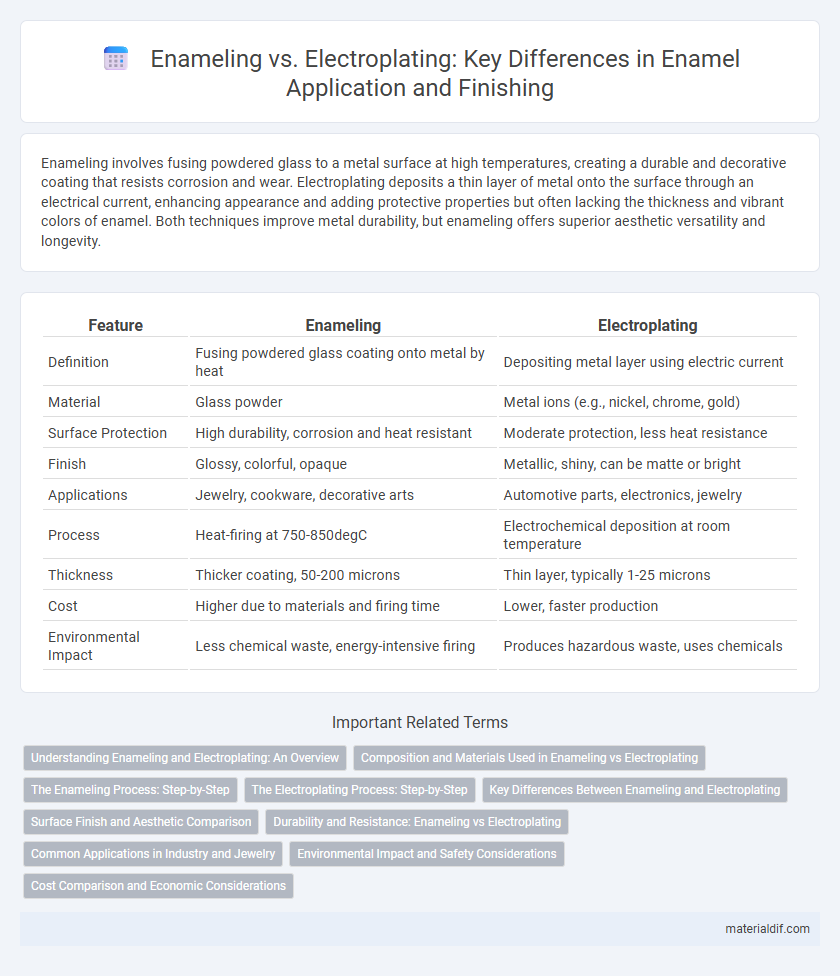

Table of Comparison

| Feature | Enameling | Electroplating |

|---|---|---|

| Definition | Fusing powdered glass coating onto metal by heat | Depositing metal layer using electric current |

| Material | Glass powder | Metal ions (e.g., nickel, chrome, gold) |

| Surface Protection | High durability, corrosion and heat resistant | Moderate protection, less heat resistance |

| Finish | Glossy, colorful, opaque | Metallic, shiny, can be matte or bright |

| Applications | Jewelry, cookware, decorative arts | Automotive parts, electronics, jewelry |

| Process | Heat-firing at 750-850degC | Electrochemical deposition at room temperature |

| Thickness | Thicker coating, 50-200 microns | Thin layer, typically 1-25 microns |

| Cost | Higher due to materials and firing time | Lower, faster production |

| Environmental Impact | Less chemical waste, energy-intensive firing | Produces hazardous waste, uses chemicals |

Understanding Enameling and Electroplating: An Overview

Enameling involves fusing powdered glass to a substrate at high temperatures to create a durable, decorative, and corrosion-resistant coating, while electroplating uses an electric current to deposit a thin metal layer onto a conductive surface. Enamel provides vibrant colors and high heat resistance unmatched by electroplated finishes, which excel in uniform metallic protection and conductivity. Both techniques serve protective and aesthetic purposes but differ significantly in process, durability, and material compatibility.

Composition and Materials Used in Enameling vs Electroplating

Enameling involves fusing powdered glass to a substrate, typically metal such as copper, silver, or gold, through high-temperature firing, resulting in a durable, glassy coating composed primarily of silica, fluxes, and metal oxides. In contrast, electroplating deposits a thin metal layer, commonly nickel, chromium, or gold, onto a conductive surface via an electrolytic process, altering surface properties without changing the substrate's bulk composition. The fundamental distinction lies in enameling's ceramic glass matrix versus electroplating's metallic coating, influencing durability, appearance, and corrosion resistance.

The Enameling Process: Step-by-Step

The enameling process involves carefully applying powdered glass onto a metal surface, typically copper or silver, and then firing it at high temperatures between 1400 and 1600 degrees Fahrenheit to create a durable, glossy coating. This step-by-step method begins with cleaning the metal to eliminate impurities, followed by multiple layers of enamel powder application and firing to achieve the desired thickness and color vibrancy. Unlike electroplating, which deposits a metal coating via electrical current, enameling fuses glass to metal, offering superior resistance to corrosion, wear, and heat.

The Electroplating Process: Step-by-Step

The electroplating process involves cleaning the metal surface, immersing it in an electrolyte solution, and applying an electric current to deposit a thin layer of metal onto the substrate. Key steps include surface preparation to remove contaminants, electrolyte bath composition selection for desired metal coating, and controlling current density to ensure uniform metal deposition. Precision in timing and voltage settings enhances coating adhesion, durability, and corrosion resistance compared to enamel's fused glass layer.

Key Differences Between Enameling and Electroplating

Enameling involves fusing powdered glass to a metal surface through high heat, creating a durable, colorful, and corrosion-resistant coating, while electroplating uses an electric current to deposit a thin metal layer onto a substrate, enhancing conductivity and aesthetic appeal. Enamel coatings are typically thicker and more resistant to wear and environmental damage, making them ideal for decorative art and cookware, whereas electroplating offers precise metal finishes suited for electronics and jewelry. The fundamental difference lies in enameling's chemical glass-metal fusion compared to electroplating's physical metal-to-metal deposition process.

Surface Finish and Aesthetic Comparison

Enameling produces a smooth, glass-like surface finish characterized by vibrant, durable colors that resist fading and corrosion, ideal for decorative applications requiring long-lasting aesthetics. Electroplating offers a metallic surface finish with a shiny, reflective appearance that can mimic precious metals but may be prone to wear and discoloration over time. Enameling delivers superior color stability and texture variety, while electroplating excels in metal-like luster and conductivity for functional, visually appealing coatings.

Durability and Resistance: Enameling vs Electroplating

Enameling provides superior durability and resistance to corrosion, chemicals, and high temperatures due to its glass-like coating fused to the metal surface. Electroplating offers thinner metal coatings that can wear off over time, reducing resistance to abrasion and chemical exposure. Enameling is preferred for applications requiring long-lasting protection and vibrant, resilient finishes.

Common Applications in Industry and Jewelry

Enameling, known for its durable, glass-like coating, is frequently applied in decorative art, high-end jewelry, and cookware due to its vibrant colors and resistance to corrosion. Electroplating, which deposits a thin metal layer such as gold, silver, or chromium on a substrate, is widely used in automotive parts, electronics, and fashion jewelry to enhance appearance and prevent oxidation. While enameling offers superior aesthetic customization and heat resistance, electroplating provides uniform metal coatings essential for electrical conductivity and wear resistance.

Environmental Impact and Safety Considerations

Enameling uses powdered glass melted onto metal surfaces, producing minimal hazardous waste and avoiding toxic heavy metals, making it safer for both workers and the environment compared to electroplating, which often involves toxic chemicals like cyanide and heavy metals such as chromium and nickel. Electroplating wastewater requires specialized treatment to remove these contaminants before discharge, posing significant environmental risks if mishandled. Enameling's lower chemical toxicity and reduced disposal challenges make it a more environmentally friendly and safer surface finishing process.

Cost Comparison and Economic Considerations

Enameling typically involves higher initial setup costs due to the need for specialized furnaces and skilled labor, but offers long-term durability and resistance to corrosion, reducing maintenance expenses. Electroplating, while generally more cost-effective upfront, incurs ongoing material costs for plating solutions and may require frequent reapplication or repairs, impacting overall economic efficiency. Choosing between enameling and electroplating depends on the specific application's budget constraints, expected lifespan, and environmental factors influencing cost-effectiveness.

Enameling vs Electroplating Infographic

materialdif.com

materialdif.com