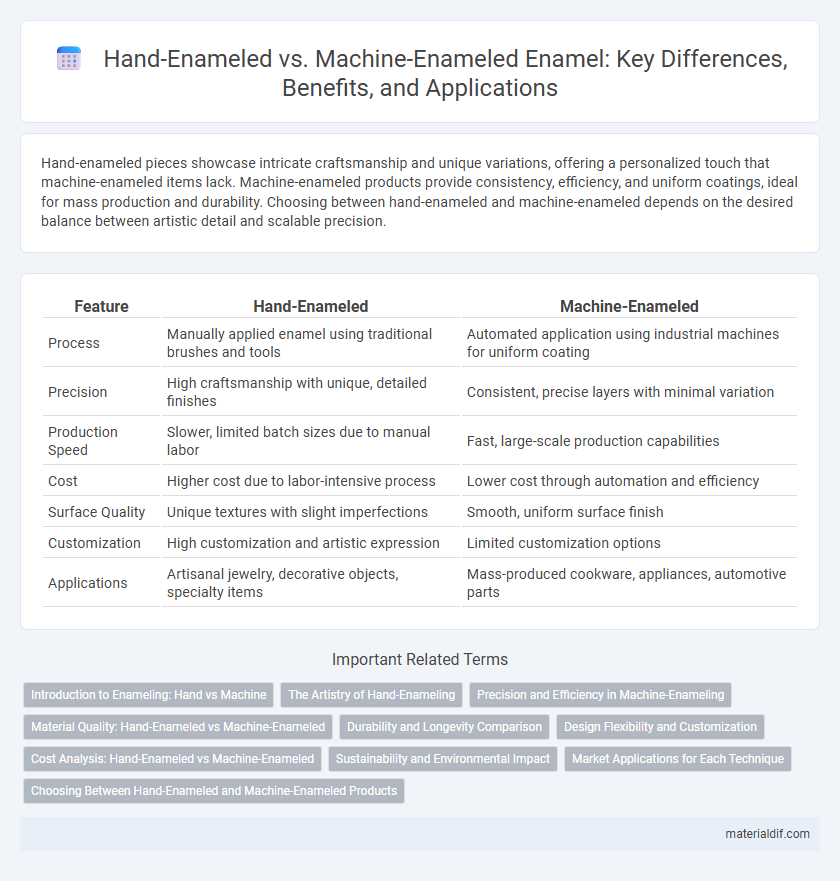

Hand-enameled pieces showcase intricate craftsmanship and unique variations, offering a personalized touch that machine-enameled items lack. Machine-enameled products provide consistency, efficiency, and uniform coatings, ideal for mass production and durability. Choosing between hand-enameled and machine-enameled depends on the desired balance between artistic detail and scalable precision.

Table of Comparison

| Feature | Hand-Enameled | Machine-Enameled |

|---|---|---|

| Process | Manually applied enamel using traditional brushes and tools | Automated application using industrial machines for uniform coating |

| Precision | High craftsmanship with unique, detailed finishes | Consistent, precise layers with minimal variation |

| Production Speed | Slower, limited batch sizes due to manual labor | Fast, large-scale production capabilities |

| Cost | Higher cost due to labor-intensive process | Lower cost through automation and efficiency |

| Surface Quality | Unique textures with slight imperfections | Smooth, uniform surface finish |

| Customization | High customization and artistic expression | Limited customization options |

| Applications | Artisanal jewelry, decorative objects, specialty items | Mass-produced cookware, appliances, automotive parts |

Introduction to Enameling: Hand vs Machine

Hand-enameled pieces feature unique, artisanal qualities achieved through meticulous manual application of glass powder onto metal surfaces, resulting in varied textures and vibrant color depth. Machine-enameled products, produced with automated precision, ensure uniform coating and consistent quality suitable for mass production of jewelry, cookware, or decorative items. Both methods utilize high-temperature fusing processes to create durable, glossy finishes, but hand enameling offers personalized craftsmanship, while machine enameling emphasizes efficiency and scalability.

The Artistry of Hand-Enameling

Hand-enameled pieces showcase intricate craftsmanship, with each layer of vitreous enamel meticulously applied and fired by skilled artisans to create rich textures and vibrant colors. Unlike machine-enameled products that rely on automated precision, hand-enameling allows for unique variations and depth, enhancing the aesthetic appeal and individuality of each item. The artistry of hand-enameling reflects centuries-old techniques that combine patience and creativity, producing timeless, high-quality jewelry and decorative objects.

Precision and Efficiency in Machine-Enameling

Machine-enameling offers superior precision by consistently applying uniform layers of enamel, ensuring high-quality finishes with minimal defects. Automated controls optimize temperature and timing, enhancing efficiency and reducing production time compared to hand-enameled methods. This technology enables large-scale manufacturing with repeatable accuracy, meeting industrial demands for durability and aesthetic consistency.

Material Quality: Hand-Enameled vs Machine-Enameled

Hand-enameled pieces typically feature higher-quality materials, as artisans select premium enamel powders and base metals to achieve superior color depth and durability. Machine-enameled products often use standardized materials optimized for mass production, which can compromise the enamel's richness and resilience. The meticulous layering and firing process in hand enameling enhances material integrity, resulting in a more robust and vibrant finish compared to machine-applied enamel.

Durability and Longevity Comparison

Hand-enameled pieces typically exhibit superior durability due to the meticulous craftsmanship involved, resulting in thicker enamel layers that resist chipping and wear over time. Machine-enameled products, while consistent and efficient in production, often have thinner enamel coatings that may be more susceptible to cracking or fading under prolonged use. Longevity in hand-enameled items is enhanced by the artisanal techniques that allow for multiple firings, creating a more resilient surface compared to the usually single-pass machine enameling process.

Design Flexibility and Customization

Hand-enameled products offer superior design flexibility and customization due to the artisan's ability to apply intricate, detailed patterns that machines cannot replicate. Machine-enameled pieces excel in consistency and efficiency but are limited to standardized designs and fewer color variations. This makes hand-enameled items ideal for bespoke projects requiring unique artistic expression and personalized detailing.

Cost Analysis: Hand-Enameled vs Machine-Enameled

Hand-enameled products typically incur higher costs due to the labor-intensive process and the expertise required, often resulting in unique, artisanal finishes. Machine-enameled items benefit from automation and scalability, significantly reducing production expenses and ensuring consistent quality across large batches. Analyzing cost factors, hand enameling suits limited runs or custom pieces, while machine enameling optimizes efficiency for mass production with lower unit costs.

Sustainability and Environmental Impact

Hand-enameled processes typically use less energy and produce less waste compared to machine-enameled methods, contributing positively to sustainability efforts. The precision of hand application reduces material excess and minimizes the release of harmful chemicals into the environment. Machine enameled production, while faster, often relies on large-scale energy consumption and generates higher volumes of emissions and waste, posing greater environmental challenges.

Market Applications for Each Technique

Hand-enameled products dominate luxury markets such as jewelry, high-end watches, and custom art pieces, where intricate designs and craftsmanship are highly valued. Machine-enameled items serve mass production sectors like household appliances, automotive components, and industrial equipment, prioritizing consistency and cost-efficiency. Market demand trends indicate increasing customization in luxury goods and scalability in industrial uses, shaping distinct roles for each enameling technique.

Choosing Between Hand-Enameled and Machine-Enameled Products

Hand-enameled products offer unique craftsmanship with intricate details and slight variations, making each piece distinct, while machine-enameled items provide uniformity and consistent quality suitable for large-scale production. Choosing between hand-enameled and machine-enameled depends on valuing artistic individuality versus precision and durability. Consider factors like the intended use, budget, and desired aesthetic to determine the best enamel application method.

Hand-Enameled vs Machine-Enameled Infographic

materialdif.com

materialdif.com