Frit composition consists primarily of finely ground glass particles fused together to create a consistent base for enamel applications, offering controlled melting behavior and durability. Slurry composition combines these frit particles with water and binders to form a spreadable mixture, enabling easier application and adherence to various substrates. The balance between frit and slurry components directly influences the final enamel's texture, adhesion, and finish quality.

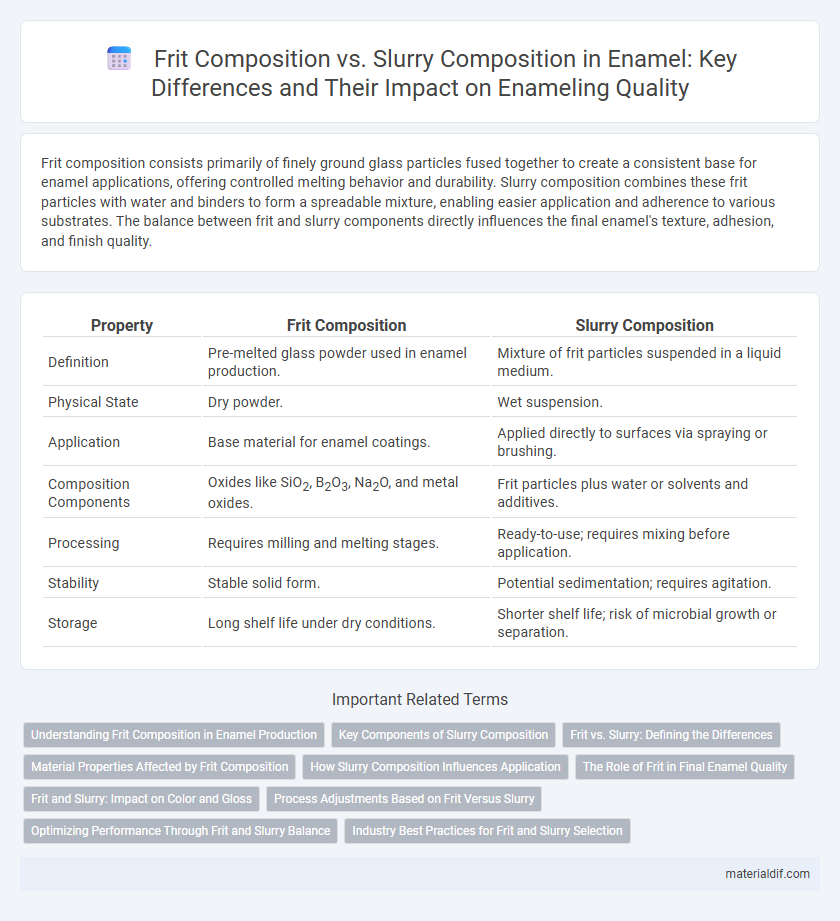

Table of Comparison

| Property | Frit Composition | Slurry Composition |

|---|---|---|

| Definition | Pre-melted glass powder used in enamel production. | Mixture of frit particles suspended in a liquid medium. |

| Physical State | Dry powder. | Wet suspension. |

| Application | Base material for enamel coatings. | Applied directly to surfaces via spraying or brushing. |

| Composition Components | Oxides like SiO2, B2O3, Na2O, and metal oxides. | Frit particles plus water or solvents and additives. |

| Processing | Requires milling and melting stages. | Ready-to-use; requires mixing before application. |

| Stability | Stable solid form. | Potential sedimentation; requires agitation. |

| Storage | Long shelf life under dry conditions. | Shorter shelf life; risk of microbial growth or separation. |

Understanding Frit Composition in Enamel Production

Frit composition in enamel production primarily consists of a carefully balanced mixture of silica, fluxes like borates and alkali metals, and stabilizers such as alumina, which together form a glassy matrix upon melting. This pre-melted glass material ensures uniform chemical and physical properties, contributing to the enamel's durability and surface finish. In contrast, slurry compositions are suspensions of ground frit particles combined with solvents and binders, designed for ease of application but dependent on the underlying frit formulation for final enamel quality.

Key Components of Slurry Composition

Slurry composition in enamel production primarily consists of finely ground frit particles suspended in water, combined with binders, dispersants, and deflocculants to ensure uniform consistency and adhesion. Key components include silica, alumina, fluxing agents like boron oxide, and metal oxides that influence the enamel's thermal and chemical properties. These elements optimize the slurry for smooth application, durability, and quality finish in the final enamel coating.

Frit vs. Slurry: Defining the Differences

Frit composition primarily consists of pre-melted glass materials that provide stability and uniformity during enamel firing, ensuring a consistent glossy finish. Slurry composition, on the other hand, combines ground frit with organic binders and water to form a paintable suspension for easier application on metal surfaces. Frit's solid glass base offers durability and resistance to thermal shock, while slurry's liquid form allows for flexible layering and precise enamel thickness control.

Material Properties Affected by Frit Composition

Frit composition significantly influences the hardness, gloss, and chemical resistance of enamel coatings, while slurry composition primarily affects application properties like viscosity and stability. Variations in frit formulations alter melting temperature, thermal expansion, and durability, ultimately determining adhesion quality and surface finish. Optimizing frit components enhances performance characteristics such as corrosion resistance and mechanical strength, critical for industrial and decorative enamel applications.

How Slurry Composition Influences Application

Slurry composition significantly influences enamel application by determining the viscosity, particle size distribution, and homogeneity of the mixture, which directly affect coating thickness and surface smoothness. A well-optimized slurry ensures uniform enamel flow and adhesion, minimizing defects such as pinholes or uneven coverage. Precise control of water-to-frit ratio and additive content enhances application consistency and curing performance, resulting in a durable and aesthetically pleasing enamel finish.

The Role of Frit in Final Enamel Quality

The frit composition directly influences the chemical durability, gloss, and adhesion of the final enamel, as it forms the glassy matrix that binds the enamel particles. Unlike slurry compositions, which include binders and water for application, frit's precise formulation determines melting behavior and compatibility with substrates during firing. Optimizing frit components such as silica, boron oxide, and alkali metals enhances enamel hardness, color stability, and resistance to corrosion.

Frit and Slurry: Impact on Color and Gloss

Frit composition primarily determines the color stability and gloss level in enamel coatings due to its glass-forming oxides and fluxing agents that control melting behavior and surface finish. Slurry composition influences the dispersion and particle size distribution of frit and pigments, affecting the uniformity of color and the smoothness of the final enamel layer. Optimizing frit and slurry formulations together enhances color vibrancy and gloss retention, critical for durable, high-quality enamel applications.

Process Adjustments Based on Frit Versus Slurry

Process adjustments based on frit composition versus slurry composition require precise control of particle size distribution and chemical formulation to ensure optimal glass forming and fusion during firing. Frit compositions demand fine-tuning of melting temperature and viscosity to achieve smooth surface finishes, whereas slurry mixtures necessitate modifications in water content and binder percentages to maintain proper adhesion and uniform coating thickness. Understanding the distinct rheological properties of frit and slurry enables manufacturers to optimize firing schedules and enhance enamel durability and appearance.

Optimizing Performance Through Frit and Slurry Balance

Frit composition directly influences the melting point, gloss, and durability of enamel, while slurry composition affects application consistency and adhesion properties. Optimizing enamel performance requires a precise balance between frit and slurry ratios to enhance surface smoothness and chemical resistance. Controlled adjustment of silica, fluxes, and binders in both components ensures optimal thermal expansion compatibility and overall coating integrity.

Industry Best Practices for Frit and Slurry Selection

Industry best practices for frit and slurry selection in enamel production emphasize precise chemical composition control, with frits commonly containing optimized blends of silica, fluxes like borates, and stabilizers to ensure thermal compatibility and durability. Slurry compositions prioritize particle size distribution and suspension stability, incorporating finely ground frits mixed with binders and dispersants to achieve uniform application and minimize defects. Selecting frit and slurry formulations based on substrate type, firing temperature, and end-use requirements significantly enhances enamel adhesion and surface quality, driving consistent industrial performance.

Frit composition vs Slurry composition Infographic

materialdif.com

materialdif.com