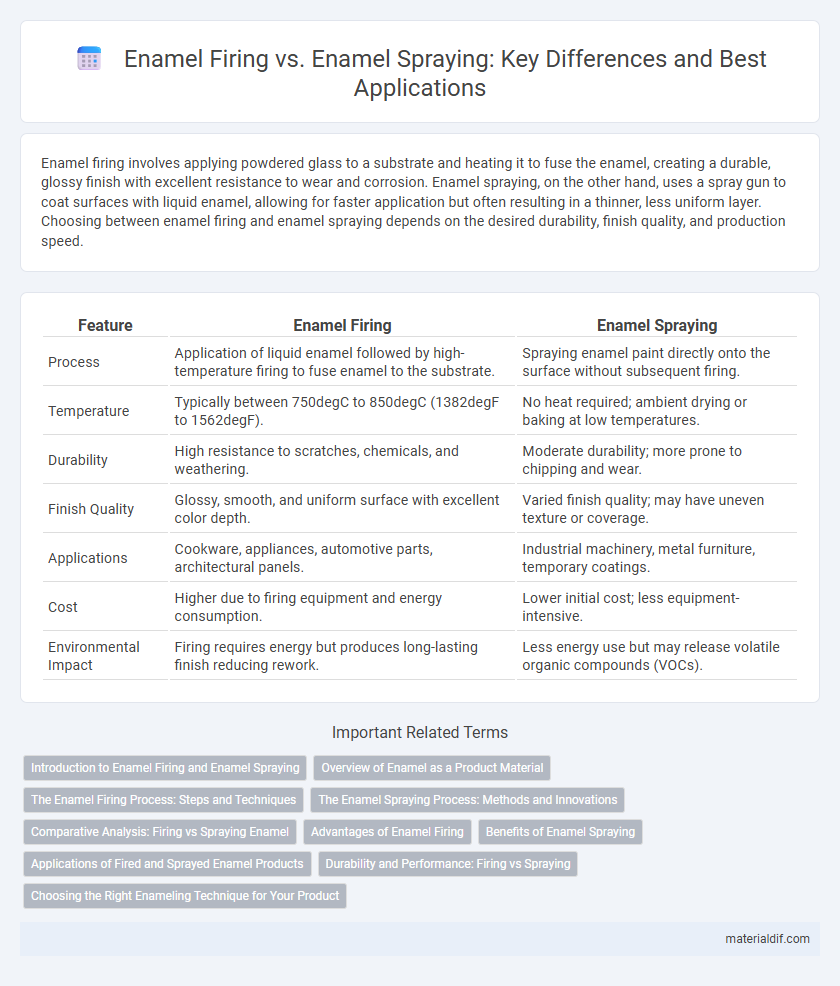

Enamel firing involves applying powdered glass to a substrate and heating it to fuse the enamel, creating a durable, glossy finish with excellent resistance to wear and corrosion. Enamel spraying, on the other hand, uses a spray gun to coat surfaces with liquid enamel, allowing for faster application but often resulting in a thinner, less uniform layer. Choosing between enamel firing and enamel spraying depends on the desired durability, finish quality, and production speed.

Table of Comparison

| Feature | Enamel Firing | Enamel Spraying |

|---|---|---|

| Process | Application of liquid enamel followed by high-temperature firing to fuse enamel to the substrate. | Spraying enamel paint directly onto the surface without subsequent firing. |

| Temperature | Typically between 750degC to 850degC (1382degF to 1562degF). | No heat required; ambient drying or baking at low temperatures. |

| Durability | High resistance to scratches, chemicals, and weathering. | Moderate durability; more prone to chipping and wear. |

| Finish Quality | Glossy, smooth, and uniform surface with excellent color depth. | Varied finish quality; may have uneven texture or coverage. |

| Applications | Cookware, appliances, automotive parts, architectural panels. | Industrial machinery, metal furniture, temporary coatings. |

| Cost | Higher due to firing equipment and energy consumption. | Lower initial cost; less equipment-intensive. |

| Environmental Impact | Firing requires energy but produces long-lasting finish reducing rework. | Less energy use but may release volatile organic compounds (VOCs). |

Introduction to Enamel Firing and Enamel Spraying

Enamel firing involves heating enamel-coated materials in a kiln or furnace to fuse the glassy coating, resulting in a durable and glossy finish commonly used on metals and ceramics. Enamel spraying is a technique where liquid enamel is applied as a fine mist onto surfaces before firing, allowing for even coverage and efficient use of materials. Both methods are essential in achieving high-quality enamel finishes, with firing providing the necessary heat treatment and spraying enabling precise enamel application.

Overview of Enamel as a Product Material

Enamel is a durable, glass-like coating fused to metal through high-temperature firing, providing corrosion resistance and a smooth, glossy finish ideal for cookware, appliances, and decorative items. Enamel firing involves heating the coated metal in a kiln to bond the enamel layer, ensuring longevity and vibrant color retention. In contrast, enamel spraying applies enamel in liquid form onto surfaces, often followed by firing or air-drying, offering versatility in application but generally less durability compared to fired enamel.

The Enamel Firing Process: Steps and Techniques

Enamel firing involves heating coated items to temperatures between 1400degF and 1600degF, causing the powdered glass to melt and fuse onto the surface, creating a durable, glossy finish. Critical steps include application of enamel powder, controlled heating in a kiln or furnace, and gradual cooling to prevent cracking or blistering. Techniques such as sifting, wet spraying, or electrostatic application optimize uniform coverage before firing ensures long-lasting adhesion and vibrant color.

The Enamel Spraying Process: Methods and Innovations

Enamel spraying involves atomizing liquid enamel onto surfaces using techniques such as air spraying, electrostatic spraying, and rotary atomizers, enhancing uniform coverage and reducing material waste. Recent innovations include automated robotic spraying systems and low-temperature curing methods, which improve precision and energy efficiency in enamel application. Advances in spray nozzle design and enamel formulation have also contributed to finer particle distribution and faster drying times, optimizing overall production quality.

Comparative Analysis: Firing vs Spraying Enamel

Enamel firing involves heating powdered glass onto a metal surface to create a durable, glossy finish, offering superior adhesion and resistance compared to enamel spraying, which applies enamel in liquid form without requiring high heat. Firing develops a chemically bonded, smooth coating ideal for jewelry and cookware, whereas spraying allows for quicker application and is suited for large surfaces with moderate durability needs. The choice hinges on the intended use; firing delivers enhanced longevity and vibrant colors, while spraying provides cost-effective versatility and ease of repair.

Advantages of Enamel Firing

Enamel firing provides superior durability and a smooth, glossy finish that enhances the enamel's resistance to corrosion and wear compared to enamel spraying. The high-temperature firing process promotes strong adhesion between the enamel coating and the substrate, resulting in longer-lasting protection and vibrant color retention. Enamel firing also allows for precise control over coating thickness and uniformity, ensuring consistent quality in industrial and artistic applications.

Benefits of Enamel Spraying

Enamel spraying offers precise control over coating thickness, resulting in a uniform and smooth finish that enhances durability and aesthetic appeal. This method reduces material waste compared to enamel firing by applying enamel directly onto the surface without the need for high-temperature kiln processes. Enamel spraying also enables faster application and curing times, making it ideal for complex shapes and large-scale industrial use where efficiency and consistency are paramount.

Applications of Fired and Sprayed Enamel Products

Fired enamel products excel in applications requiring durable, heat-resistant coatings for appliances, cookware, and architectural surfaces due to their strong adhesion and longevity. Sprayed enamel is preferred in automotive, industrial equipment, and furniture industries where fast application and uniform coverage on complex shapes are critical. The firing process ensures a hard, glossy finish ideal for high-temperature environments, while sprayed enamel offers flexibility and efficiency for large-scale decorative and protective coatings.

Durability and Performance: Firing vs Spraying

Enamel firing creates a durable, glass-like coating by melting powdered glass onto a substrate, resulting in superior adhesion and resistance to wear, heat, and corrosion. In contrast, enamel spraying applies a liquid enamel layer, which typically requires curing but may offer less uniform thickness and reduced long-term durability. Firing enhances performance through robust chemical bonds, while spraying provides quicker application but generally lower resistance to mechanical and environmental stress.

Choosing the Right Enameling Technique for Your Product

Selecting the optimal enameling technique depends on factors such as surface complexity, production volume, and desired finish durability. Enamel firing offers a robust, glossy finish ideal for intricate designs and high-temperature resistance, while enamel spraying provides faster application and versatility on larger or irregular surfaces. Evaluate the product's material compatibility and end-use environment to ensure the chosen method enhances both aesthetic appeal and longevity.

Enamel Firing vs Enamel Spraying Infographic

materialdif.com

materialdif.com