Fired enamel undergoes a high-temperature process that fuses powdered glass to a metal surface, creating a durable, glossy, and heat-resistant coating. Unfired enamel, often in paste or paint form, lacks this heat treatment, resulting in a softer finish that is more prone to chipping and less resistant to wear. The firing process enhances the enamel's permanence, color vibrancy, and structural integrity, making it ideal for jewelry, decorative art, and industrial applications.

Table of Comparison

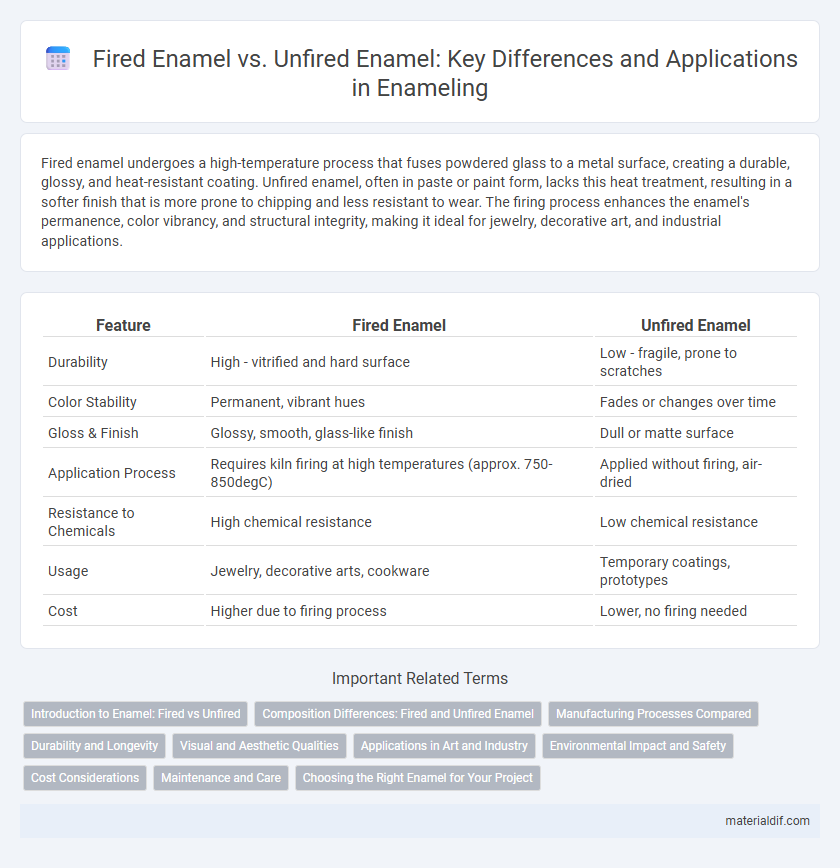

| Feature | Fired Enamel | Unfired Enamel |

|---|---|---|

| Durability | High - vitrified and hard surface | Low - fragile, prone to scratches |

| Color Stability | Permanent, vibrant hues | Fades or changes over time |

| Gloss & Finish | Glossy, smooth, glass-like finish | Dull or matte surface |

| Application Process | Requires kiln firing at high temperatures (approx. 750-850degC) | Applied without firing, air-dried |

| Resistance to Chemicals | High chemical resistance | Low chemical resistance |

| Usage | Jewelry, decorative arts, cookware | Temporary coatings, prototypes |

| Cost | Higher due to firing process | Lower, no firing needed |

Introduction to Enamel: Fired vs Unfired

Fired enamel is a glassy coating fused onto metal through high-temperature kiln firing, creating a durable, glossy surface resistant to corrosion and wear. Unfired enamel, often in the form of enamel powders or pastes, lacks this heat treatment and remains pliable but less durable and prone to scratching or fading. Understanding the chemical and physical differences between fired and unfired enamels is essential for applications in jewelry, decorative arts, and industrial components.

Composition Differences: Fired and Unfired Enamel

Fired enamel consists of powdered glass fused onto a metal substrate through high-temperature kiln firing, resulting in a hard, durable, and glossy surface primarily composed of silica, fluxes, and metal oxides. Unfired enamel, often called cold enamel, contains synthetic resins, pigments, and fillers that mimic the appearance of traditional enamel without requiring heat, offering a softer and more flexible finish. The key compositional difference lies in fired enamel's vitrified silica matrix versus unfired enamel's polymer-based formulation, impacting their durability and application methods.

Manufacturing Processes Compared

Fired enamel undergoes a high-temperature kiln process, typically between 750degC and 850degC, which fuses powdered glass to a metal substrate, creating a durable, glossy coating resistant to corrosion and wear. Unfired enamel, or cold enamel, uses air-drying polymer resins that harden without heat, resulting in a softer, less durable finish suitable for decorative applications but lacking the resilience of fired enamel. The firing process in manufacturing not only enhances adhesion and durability but also defines the final enamel's resistance to thermal shock and chemical exposure.

Durability and Longevity

Fired enamel undergoes high-temperature heating, which chemically bonds the glass powder to the metal surface, resulting in superior durability and resistance to chipping, fading, and corrosion. Unfired enamel lacks this hardened bond, making it more susceptible to scratches, wear, and discoloration over time. Consequently, fired enamel is favored for applications requiring long-lasting, resilient finishes in jewelry, cookware, and decorative arts.

Visual and Aesthetic Qualities

Fired enamel offers a durable, glossy finish with vibrant, permanent colors that resist fading and provide a smooth, glass-like surface. Unfired enamel lacks the hardened, polished sheen and appears matte or chalky, often exhibiting less color depth and vibrancy. The firing process enhances the enamel's translucency and brilliance, crucial for high-quality jewelry and decorative art pieces.

Applications in Art and Industry

Fired enamel, created by heating powdered glass fused to a metal surface, offers increased durability and vibrant colors, making it ideal for fine art pieces, jewelry, and industrial coatings requiring corrosion resistance. Unfired enamel, still in its powdered or paste form, allows artists to experiment with textures and layering before firing and is commonly used in decorative work and preliminary design stages in manufacturing. Industries benefit from fired enamel's hardness and chemical inertness for functional items like cookware, signage, and electrical components, where longevity and aesthetic appeal are critical.

Environmental Impact and Safety

Fired enamel undergoes a high-temperature kiln process that stabilizes the material, reducing the risk of toxic leaching and enhancing its durability, which minimizes environmental contamination over time. Unfired enamel contains raw or partially processed compounds that may release hazardous substances like heavy metals during handling or disposal, posing greater environmental and health risks. Choosing fired enamel significantly lowers exposure to harmful emissions and promotes safer waste management due to its chemically inert and robust nature.

Cost Considerations

Fired enamel involves heating the enamel to high temperatures, resulting in a durable and glossy finish, but this process increases production costs due to energy consumption and specialized kiln equipment. Unfired enamel, applied without heat, reduces expenses by eliminating firing stages and minimizing resource use, though it may sacrifice some long-term durability and vibrancy. Choosing between fired and unfired enamel depends on budget constraints and the desired balance between quality and cost-efficiency.

Maintenance and Care

Fired enamel creates a durable, glass-like surface that resists scratches, stains, and corrosion, requiring minimal maintenance beyond gentle cleaning with non-abrasive materials. Unfired enamel remains porous and sensitive, demanding careful handling to avoid chipping, discoloration, and damage from moisture exposure. Proper care for fired enamel extends its vibrancy and longevity, while unfired enamel necessitates more frequent touch-ups and protective measures to maintain its appearance.

Choosing the Right Enamel for Your Project

Fired enamel offers superior durability and vibrant color retention due to its fusion onto metal at high temperatures, making it ideal for long-lasting jewelry and art pieces. Unfired enamel, often used in crafts or decorative work, provides greater flexibility for layering and adjustments but lacks the permanence of fired enamel. Selecting the right enamel depends on project requirements for durability, finish, and whether the piece will endure wear or environmental exposure.

Fired Enamel vs Unfired Enamel Infographic

materialdif.com

materialdif.com