Cast iron enameling offers superior heat retention and durability, making it ideal for heavy-duty cookware and appliances, while steel enameling provides greater flexibility and resistance to impact due to its lighter and more malleable nature. Cast iron's porous surface bonds well with enamel, ensuring a longer-lasting, chip-resistant finish compared to steel. Enamel-coated steel cookware is typically lighter and heats up faster, but cast iron enameling is favored for even heat distribution and retention.

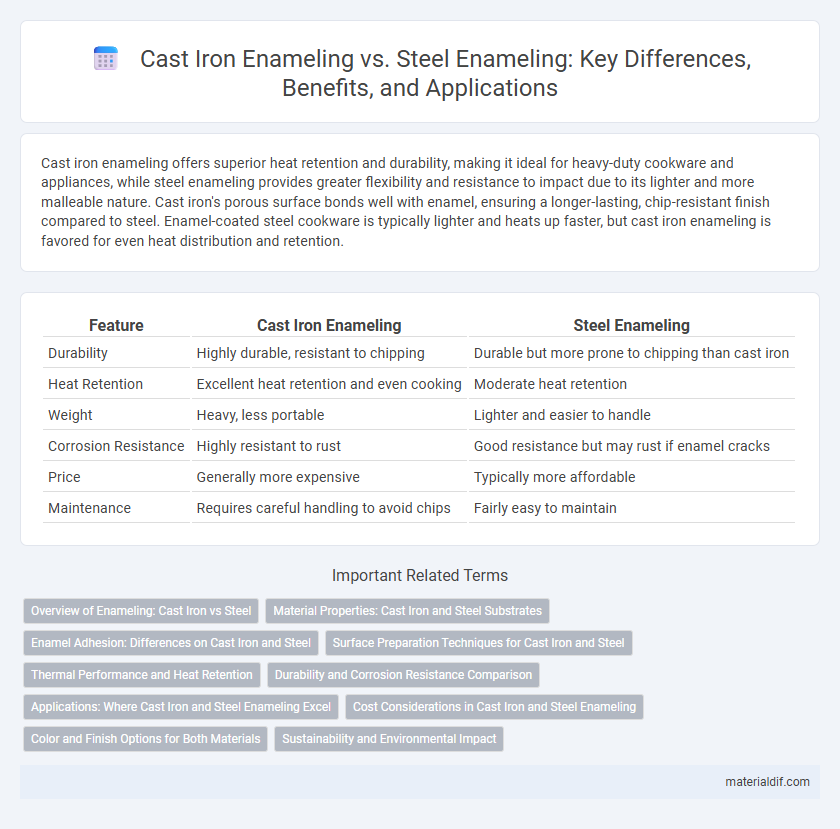

Table of Comparison

| Feature | Cast Iron Enameling | Steel Enameling |

|---|---|---|

| Durability | Highly durable, resistant to chipping | Durable but more prone to chipping than cast iron |

| Heat Retention | Excellent heat retention and even cooking | Moderate heat retention |

| Weight | Heavy, less portable | Lighter and easier to handle |

| Corrosion Resistance | Highly resistant to rust | Good resistance but may rust if enamel cracks |

| Price | Generally more expensive | Typically more affordable |

| Maintenance | Requires careful handling to avoid chips | Fairly easy to maintain |

Overview of Enameling: Cast Iron vs Steel

Enameling on cast iron involves applying a glassy coating that enhances corrosion resistance and heat retention, making it ideal for cookware like Dutch ovens. Steel enameling typically features a smoother, thinner enamel layer that offers better impact resistance and lighter weight, suited for kitchen appliances and bakeware. Both methods utilize high-temperature fusing but differ in bonding mechanisms and substrate properties, influencing durability and performance.

Material Properties: Cast Iron and Steel Substrates

Cast iron enameling offers exceptional heat retention and thermal conductivity due to its dense and porous structure, enhancing the enamel's durability and resistance to chipping. Steel enameling benefits from a lighter, more flexible substrate with higher tensile strength, allowing for thinner enamel coatings and greater impact resistance. The differences in thermal expansion between cast iron and steel significantly influence enamel adhesion and longevity under varying temperature conditions.

Enamel Adhesion: Differences on Cast Iron and Steel

Enamel adhesion on cast iron typically exhibits superior durability due to the material's rougher surface and inherent porosity, which allows the enamel to bond more effectively. Steel enameling often requires surface treatments such as sandblasting or chemical etching to enhance enamel adhesion, as steel's smoother surface and lower porosity can lead to weaker enamel bonds. Differences in thermal expansion rates between enamel and the substrate material also affect adhesion, with cast iron's closer coefficient of thermal expansion to enamel reducing stress and minimizing the risk of chipping.

Surface Preparation Techniques for Cast Iron and Steel

Cast iron enameling requires thorough surface preparation, including sandblasting or shot blasting to remove rust and scale, followed by degreasing to ensure optimal enamel adhesion. Steel enameling involves similar abrasive cleaning methods but often demands more precise control of surface roughness due to its denser and more uniform structure. Both materials benefit from acid etching or phosphating treatments to enhance enamel bonding and prevent defects during the firing process.

Thermal Performance and Heat Retention

Cast iron enameling offers superior heat retention due to the material's high thermal mass, allowing cookware to maintain steady temperatures for extended periods during cooking. Steel enameling features quicker heat responsiveness and more even heat distribution but generally cools faster compared to cast iron. The enhanced thermal performance of cast iron enamel makes it ideal for slow-cooking and simmering, while steel enamel suits recipes requiring rapid temperature changes.

Durability and Corrosion Resistance Comparison

Cast iron enameling offers superior durability due to its thicker enamel coating, which creates a robust barrier against chipping and scratching compared to steel enameling. Corrosion resistance in cast iron enameling is enhanced by its heavy-duty enamel layer that protects the iron substrate from moisture and rust more effectively than the thinner enamel on steel. Steel enameling is more prone to corrosion over time because the thinner enamel coating can wear down, exposing the metal beneath to oxidation.

Applications: Where Cast Iron and Steel Enameling Excel

Cast iron enameling excels in cookware and heavy-duty industrial applications due to its excellent heat retention and resistance to thermal shock, making it ideal for stovetop pots, Dutch ovens, and baking dishes. Steel enameling is preferred in household appliances, sinks, and indoor or outdoor architectural elements because of its lighter weight, superior impact resistance, and versatile design options. Both materials deliver durable, corrosion-resistant surfaces, but cast iron is best suited for high-heat, heavy-use environments while steel offers greater flexibility in shape and installation.

Cost Considerations in Cast Iron and Steel Enameling

Cast iron enameling generally incurs higher costs due to the thicker base material and longer firing times required for proper adhesion, driving up energy consumption and labor. Steel enameling offers a more cost-effective solution with thinner substrates that reduce material expenses and shorten processing durations while maintaining durability. The difference in casting complexities and furnace requirements also affects overall production budgets between cast iron and steel enamel-coated products.

Color and Finish Options for Both Materials

Cast iron enameling offers a rich, durable finish with deep, vibrant color options that enhance the metal's natural heat retention properties, making it ideal for cookware and decorative items. Steel enameling provides a smoother, more uniform surface with a wider range of glossy and matte finishes, accommodating diverse industrial and aesthetic applications. Both materials support high-quality enamel coatings, but cast iron excels in long-lasting color depth while steel allows for greater variation in finish textures.

Sustainability and Environmental Impact

Cast iron enameling offers superior durability and corrosion resistance, reducing the need for frequent replacements and minimizing waste. Steel enameling, while lighter, often involves higher energy consumption during production due to steel's thermal properties and can generate more emissions. Both materials benefit from enamel coatings that extend product lifespan, but cast iron's longer durability makes it a more sustainable choice for environmentally conscious manufacturing.

Cast iron enameling vs Steel enameling Infographic

materialdif.com

materialdif.com