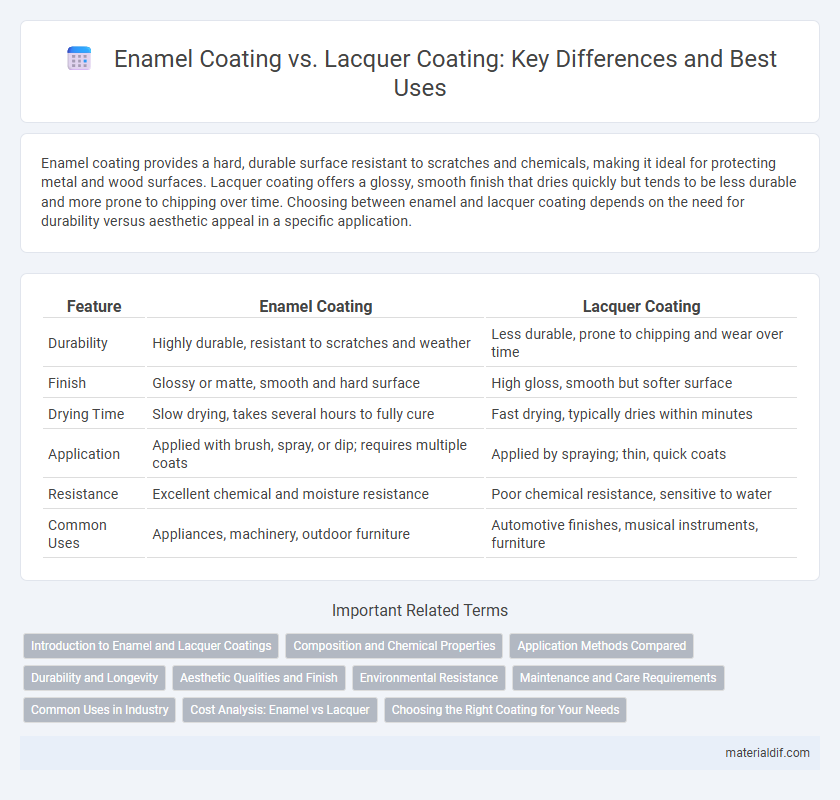

Enamel coating provides a hard, durable surface resistant to scratches and chemicals, making it ideal for protecting metal and wood surfaces. Lacquer coating offers a glossy, smooth finish that dries quickly but tends to be less durable and more prone to chipping over time. Choosing between enamel and lacquer coating depends on the need for durability versus aesthetic appeal in a specific application.

Table of Comparison

| Feature | Enamel Coating | Lacquer Coating |

|---|---|---|

| Durability | Highly durable, resistant to scratches and weather | Less durable, prone to chipping and wear over time |

| Finish | Glossy or matte, smooth and hard surface | High gloss, smooth but softer surface |

| Drying Time | Slow drying, takes several hours to fully cure | Fast drying, typically dries within minutes |

| Application | Applied with brush, spray, or dip; requires multiple coats | Applied by spraying; thin, quick coats |

| Resistance | Excellent chemical and moisture resistance | Poor chemical resistance, sensitive to water |

| Common Uses | Appliances, machinery, outdoor furniture | Automotive finishes, musical instruments, furniture |

Introduction to Enamel and Lacquer Coatings

Enamel coatings provide a durable, hard finish ideal for surfaces requiring long-lasting protection, often composed of oil-based or water-based resins that cure into a glossy or matte layer. Lacquer coatings dry quickly through solvent evaporation, resulting in a smooth, high-gloss finish commonly used for wood and metal surfaces due to their fast drying and easy application. Both enamel and lacquer coatings offer unique benefits in terms of durability, drying time, and appearance, catering to different industrial and decorative needs.

Composition and Chemical Properties

Enamel coatings consist primarily of synthetic resins such as alkyd, epoxy, or polyurethane, offering high durability and chemical resistance due to their cross-linked polymer structures. Lacquer coatings are typically nitrocellulose or acrylic-based, characterized by fast evaporation of solvents, resulting in a hard, glossy finish but lower chemical resistance compared to enamel. The chemical stability of enamel makes it suitable for protective applications, while lacquer's quick-drying properties favor aesthetic surface treatments.

Application Methods Compared

Enamel coating is typically applied using spray guns or brushes, allowing for a thick, durable layer that provides excellent protection against corrosion and wear. Lacquer coating, on the other hand, is usually sprayed on in thin, fast-drying layers, resulting in a smooth, glossy finish but with less impact resistance compared to enamel. The application method for enamel demands longer curing times, while lacquer's rapid drying suits high-volume production with quicker turnaround.

Durability and Longevity

Enamel coating offers superior durability and longevity due to its hard, glass-like finish that resists chipping, scratching, and weathering. Lacquer coating, while providing a glossy, smooth surface, tends to be more prone to cracking and wears down faster under harsh conditions. The strong adhesion and chemical resistance of enamel make it ideal for long-lasting protection on metal and wood surfaces.

Aesthetic Qualities and Finish

Enamel coating offers a durable, glossy finish with a smooth, glass-like surface that enhances color vibrancy and provides excellent resistance to chipping and fading. Lacquer coating delivers a high-shine, polished appearance with a thinner, more delicate layer that can be easily repaired or refinished, making it ideal for fine furniture and decorative objects. The choice between enamel and lacquer coatings depends on the desired aesthetic durability and surface texture, with enamel providing a tougher, long-lasting sheen and lacquer producing a richer, more lustrous finish.

Environmental Resistance

Enamel coating offers superior environmental resistance due to its hard, durable finish that withstands moisture, UV radiation, and chemical exposure better than lacquer coatings. Lacquer coatings provide a glossy appearance but are more vulnerable to cracking, fading, and damage from environmental factors like humidity and temperature fluctuations. Enamel's chemically resistant surface makes it ideal for outdoor applications where long-lasting protection against corrosion and weathering is essential.

Maintenance and Care Requirements

Enamel coating offers superior durability and is resistant to chipping and scratching, requiring minimal maintenance such as occasional cleaning with mild soap and water. Lacquer coating demands more frequent upkeep, as it is prone to yellowing and damage from moisture, necessitating careful cleaning with specialized solvents and regular polishing. Proper maintenance extends the lifespan of enamel coatings more effectively than lacquer coatings, making enamel a preferred choice for high-traffic or exposed surfaces.

Common Uses in Industry

Enamel coatings are widely used in automotive and appliance industries for their durable, glossy finish and resistance to heat and chemicals. Lacquer coatings are prevalent in furniture and musical instrument manufacturing due to their fast-drying properties and ability to produce a smooth, high-gloss surface. Both coatings serve distinct industrial purposes, with enamel favored for protective durability and lacquer chosen for aesthetic refinement.

Cost Analysis: Enamel vs Lacquer

Enamel coatings generally cost more upfront due to higher raw material and production expenses but offer superior durability, reducing long-term maintenance costs compared to lacquer. Lacquer coatings are less expensive initially and dry faster, though they often require more frequent reapplications, increasing lifetime expenses. Choosing between enamel and lacquer depends on balancing initial investment against durability and maintenance frequency in the specific application context.

Choosing the Right Coating for Your Needs

Enamel coating offers superior durability and resistance to heat, chemicals, and wear, making it ideal for tools, appliances, and automotive parts requiring long-lasting protection. Lacquer coating provides a glossy finish with fast drying times, suitable for woodwork and decorative surfaces where aesthetic appeal and smooth texture are prioritized. Choosing between enamel and lacquer coatings depends on balancing the need for durability against visual finish and drying speed for the intended application.

Enamel Coating vs Lacquer Coating Infographic

materialdif.com

materialdif.com