Hot enameling involves fusing powdered glass to a metal surface at high temperatures, creating a durable and glossy finish ideal for jewelry and decorative art. Cold enameling uses resin or epoxy to mimic the glassy appearance without heat, offering quicker application and flexibility but with less resilience to wear and heat exposure. Both techniques provide vibrant color options, but hot enameling ensures superior longevity and resistance in demanding conditions.

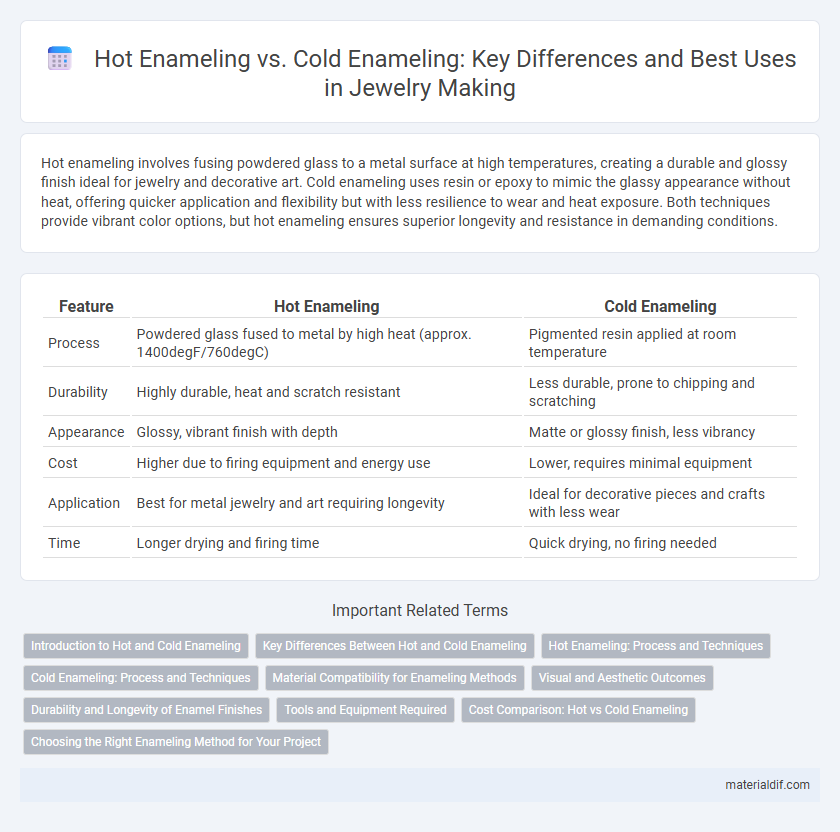

Table of Comparison

| Feature | Hot Enameling | Cold Enameling |

|---|---|---|

| Process | Powdered glass fused to metal by high heat (approx. 1400degF/760degC) | Pigmented resin applied at room temperature |

| Durability | Highly durable, heat and scratch resistant | Less durable, prone to chipping and scratching |

| Appearance | Glossy, vibrant finish with depth | Matte or glossy finish, less vibrancy |

| Cost | Higher due to firing equipment and energy use | Lower, requires minimal equipment |

| Application | Best for metal jewelry and art requiring longevity | Ideal for decorative pieces and crafts with less wear |

| Time | Longer drying and firing time | Quick drying, no firing needed |

Introduction to Hot and Cold Enameling

Hot enameling involves fusing powdered glass to metal at temperatures typically ranging from 1,380degF to 1,560degF, creating a durable, glossy coating renowned for its resistance to corrosion and wear. Cold enameling, also known as cold paint or epoxy enameling, applies pigmented resin-based compounds that cure at room temperature, offering ease of use and faster application without the need for heat. Each technique serves distinct purposes in jewelry, decorative arts, and industrial applications, with hot enameling favoring long-lasting finishes and cold enameling emphasizing convenience and color versatility.

Key Differences Between Hot and Cold Enameling

Hot enameling involves fusing powdered glass to a metal surface by heating it between 1,380 to 1,560 degrees Fahrenheit, creating a durable, glossy coating ideal for jewelry and cookware. Cold enameling uses resin-based compounds applied at room temperature, resulting in a flexible and less heat-resistant finish suitable for decorative crafts and quick repairs. The key differences lie in temperature requirements, durability, and application methods, with hot enameling offering superior hardness and longevity compared to the more versatile but softer cold enameling.

Hot Enameling: Process and Techniques

Hot enameling involves fusing powdered glass onto metal surfaces by heating them to temperatures between 1,300degF and 1,600degF, creating a durable, glossy finish. Techniques such as cloisonne, champleve, and grisaille rely on precision heating to achieve vibrant colors and intricate designs. This process enhances hardness and corrosion resistance, making it a preferred method for decorative and functional metalwork.

Cold Enameling: Process and Techniques

Cold enameling involves applying colored epoxy resin or polymer-based enamel onto a surface without the need for firing in a kiln, making it ideal for delicate materials that cannot withstand high temperatures. The process includes precise layering, curing at ambient temperatures, and often involves hand-painting or using molds to achieve detailed designs and smooth finishes. Techniques such as airbrushing, stamping, and decal application enhance the versatility of cold enameling, allowing for vibrant colors and intricate patterns with durable, chip-resistant results.

Material Compatibility for Enameling Methods

Hot enameling requires base metals like copper, silver, or gold to withstand high temperatures typically between 1400degF to 1600degF, ensuring proper fusion of powdered glass and metal surfaces. Cold enameling is compatible with a broader range of materials, including non-metal substrates such as wood, glass, and certain plastics, as it uses resin-based enamels cured at room temperature or with UV light. Selecting the appropriate enameling technique depends on the thermal tolerance and chemical properties of the material to achieve optimal adhesion and durability.

Visual and Aesthetic Outcomes

Hot enameling produces vibrant, glossy finishes with deep color saturation and smooth surfaces due to the high-temperature fusing process. Cold enameling offers more subtle, matte textures and allows for intricate layering without heat, resulting in delicate, handcrafted visual effects. The choice between hot and cold enameling significantly impacts the final aesthetic, with hot enameling emphasizing durability and brilliance, while cold enameling highlights detailed artistry and soft finishes.

Durability and Longevity of Enamel Finishes

Hot enameling involves fusing powdered glass to metal at high temperatures, resulting in a highly durable and long-lasting finish resistant to chipping and fading. Cold enameling, applied at room temperature, offers less durability and tends to wear down more quickly, making it less suitable for items exposed to frequent handling or harsh conditions. The superior hardness and chemical resistance of hot enamel ensure prolonged aesthetic appeal and protection compared to cold enamel finishes.

Tools and Equipment Required

Hot enameling requires a kiln or torch capable of reaching temperatures between 1,380degF and 1,560degF to fuse powdered glass onto metal surfaces, along with heat-resistant tweezers, kiln gloves, and a sifter for even glass application. Cold enameling utilizes epoxy or resin-based enamels that cure at room temperature, demanding tools such as mixing sticks, disposable palettes, fine brushes, and protective gloves to apply and set the enamel without heat. Both methods require clean, smooth metal surfaces prepared with sanding and degreasing tools to ensure proper adhesion and a flawless finish.

Cost Comparison: Hot vs Cold Enameling

Hot enameling typically incurs higher costs due to elevated energy consumption and specialized kiln equipment, whereas cold enameling presents a more budget-friendly alternative with lower energy requirements and minimal setup expenses. The material costs for hot enameling can also be higher because of heat-resistant enamels and substrates, while cold enameling uses more affordable resin-based formulations. Overall, cold enameling offers significant cost savings in production, making it favorable for small-scale or budget-conscious projects compared to the more capital and energy-intensive hot enameling process.

Choosing the Right Enameling Method for Your Project

Hot enameling involves fusing powdered glass to a metal surface at temperatures between 1400degF and 1600degF, producing durable, glossy finishes ideal for jewelry and cookware. Cold enameling uses epoxy or polyurethane resins applied at room temperature, offering quicker, less heat-sensitive options suited for intricate designs and non-metal substrates. Choose hot enameling for long-lasting, heat-resistant coatings and cold enameling for flexibility and ease of application on delicate or heat-sensitive materials.

Hot Enameling vs Cold Enameling Infographic

materialdif.com

materialdif.com