Stove enamel is specifically formulated to withstand high temperatures, providing durable protection and a glossy finish on cookware and appliances. Synthetic enamel, often used in industrial applications, offers enhanced chemical resistance and flexibility but may not endure extreme heat as effectively. Choosing between stove enamel and synthetic enamel depends on the required heat tolerance and surface durability for the intended use.

Table of Comparison

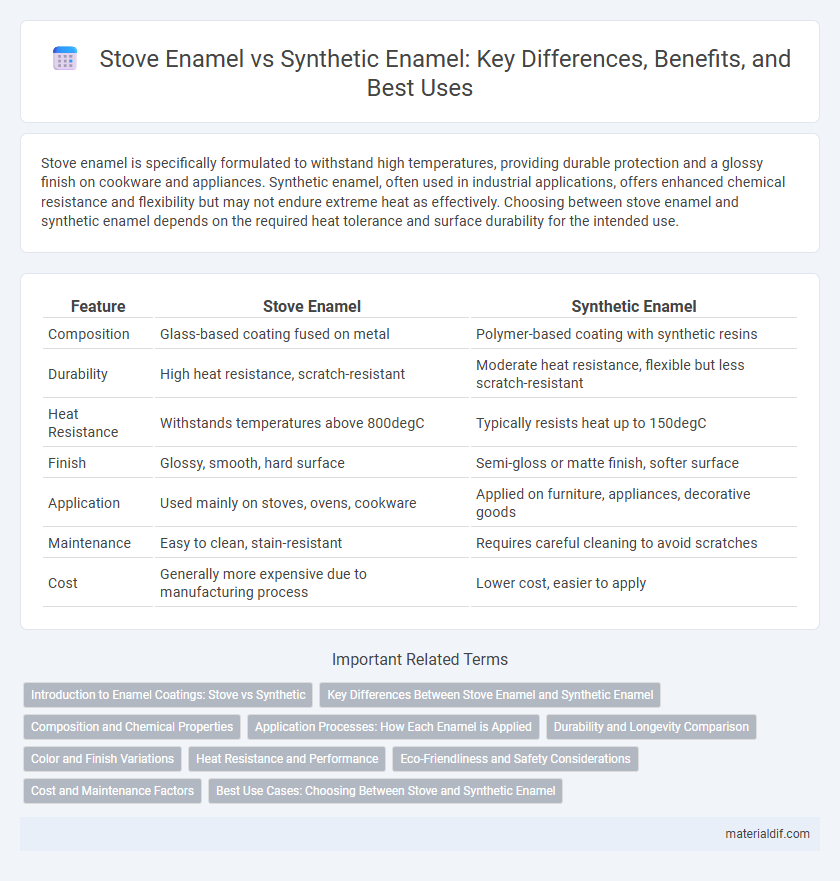

| Feature | Stove Enamel | Synthetic Enamel |

|---|---|---|

| Composition | Glass-based coating fused on metal | Polymer-based coating with synthetic resins |

| Durability | High heat resistance, scratch-resistant | Moderate heat resistance, flexible but less scratch-resistant |

| Heat Resistance | Withstands temperatures above 800degC | Typically resists heat up to 150degC |

| Finish | Glossy, smooth, hard surface | Semi-gloss or matte finish, softer surface |

| Application | Used mainly on stoves, ovens, cookware | Applied on furniture, appliances, decorative goods |

| Maintenance | Easy to clean, stain-resistant | Requires careful cleaning to avoid scratches |

| Cost | Generally more expensive due to manufacturing process | Lower cost, easier to apply |

Introduction to Enamel Coatings: Stove vs Synthetic

Enamel coatings consist of a glassy layer fused to metal surfaces, providing durability and resistance to heat and corrosion. Stove enamel specifically refers to heat-resistant coatings designed for cookware and stoves, offering superior protection against high temperatures and mechanical wear. Synthetic enamel, often composed of polymer-based resins, emphasizes flexibility and chemical resistance, making it suitable for various industrial applications where thermal resistance is less critical.

Key Differences Between Stove Enamel and Synthetic Enamel

Stove enamel is a specialized glass-like coating designed to withstand high temperatures and provide durability on cookware and appliances, offering excellent heat resistance and chemical inertness. Synthetic enamel, often made from polymer-based materials, offers greater flexibility, quicker drying times, and enhanced resistance to chipping but may have lower heat tolerance compared to stove enamel. The key differences lie in their composition, heat resistance levels, and typical applications, where stove enamel excels in high-temperature environments and synthetic enamel suits decorative or less heat-intensive uses.

Composition and Chemical Properties

Stove enamel is primarily composed of natural glassy materials fused with minerals like silica, feldspar, and borates, creating a hard, heat-resistant coating with excellent thermal stability and chemical inertness. Synthetic enamel, on the other hand, incorporates engineered polymers and resins combined with inorganic pigments and fillers, offering enhanced flexibility, impact resistance, and tailored chemical properties such as increased resistance to acids and alkalis. Chemical properties of stove enamel favor high-temperature durability and resistance to thermal shock, while synthetic enamel excels in corrosion resistance and adaptability to varying environmental conditions.

Application Processes: How Each Enamel is Applied

Stove enamel is typically applied through a high-temperature firing process where powdered glass enamel is fused onto metal surfaces for heat resistance and durability. Synthetic enamel, often a type of polymer-based coating, is applied via spraying or brushing at ambient temperatures, relying on chemical curing or drying rather than firing. These distinct application methods influence the enamel's adhesion, finish, and suitability for different stove components.

Durability and Longevity Comparison

Stove enamel is renowned for its high durability and resistance to heat, making it ideal for appliances exposed to constant temperature fluctuations. Synthetic enamel often incorporates advanced polymers, offering enhanced resistance to chipping and corrosion, but may lack the same heat tolerance as traditional stove enamel. When comparing longevity, stove enamel generally outperforms synthetic versions in maintaining structural integrity under prolonged thermal stress.

Color and Finish Variations

Stove enamel offers rich, durable color varieties with a glossy finish that withstands high temperatures and frequent cleaning, making it ideal for kitchen appliances. Synthetic enamel provides a broader spectrum of color options and finishes, including matte and satin, allowing for more customized aesthetic choices in various applications. Both types deliver distinct visual appeal, but stove enamel excels in heat resistance while synthetic enamel prioritizes design versatility.

Heat Resistance and Performance

Stove enamel offers superior heat resistance, designed to withstand extreme temperatures without cracking or discoloration, making it ideal for cooking surfaces. Synthetic enamel, while versatile and often more affordable, typically exhibits lower heat tolerance and may degrade or discolor under prolonged high heat exposure. Choosing stove enamel ensures enhanced durability and consistent performance in high-temperature environments compared to synthetic alternatives.

Eco-Friendliness and Safety Considerations

Stove enamel, composed primarily of natural glass-like coatings fused to metal at high temperatures, offers superior durability and chemical stability, making it eco-friendly due to its long lifespan and inert nature, which minimizes harmful emissions. Synthetic enamels often contain volatile organic compounds and heavy metals that can pose environmental hazards and health risks during manufacturing and disposal. Choosing stove enamel reduces exposure to toxic substances and supports sustainable practices by enabling easier recycling and lower environmental impact.

Cost and Maintenance Factors

Stove enamel typically costs more upfront due to its durable, heat-resistant ceramic composition, which withstands high temperatures without discoloration or cracking. Synthetic enamel, made from polymer-based materials, offers lower initial costs but may require more frequent maintenance and replacement due to lower heat resistance and susceptibility to wear. Maintenance for stove enamel involves careful cleaning with non-abrasive products to preserve its glossy finish, while synthetic enamel may need more frequent touch-ups and repairs to maintain appearance and functionality.

Best Use Cases: Choosing Between Stove and Synthetic Enamel

Stove enamel, known for its durability and high resistance to heat, is ideal for cookware and high-temperature appliances where long-lasting protection is essential. Synthetic enamel, offering greater flexibility and a wider range of colors, is better suited for decorative items and applications requiring intricate designs or lower heat exposure. Selecting between stove and synthetic enamel depends on the specific heat resistance needs, aesthetic preferences, and durability requirements of the project.

Stove enamel vs synthetic enamel Infographic

materialdif.com

materialdif.com