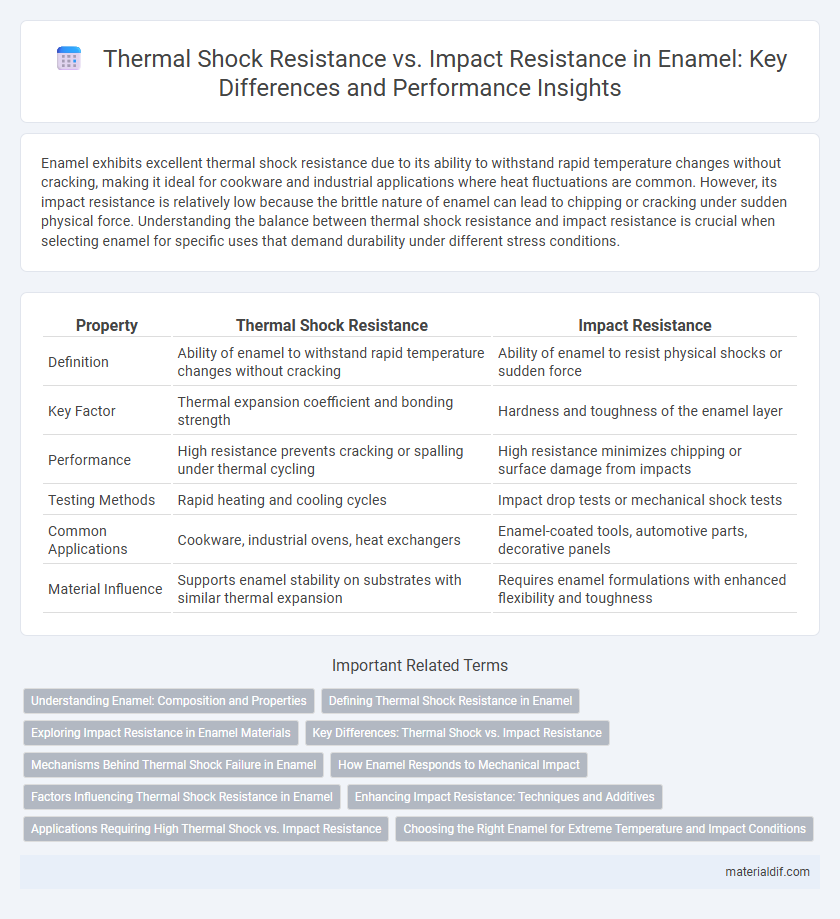

Enamel exhibits excellent thermal shock resistance due to its ability to withstand rapid temperature changes without cracking, making it ideal for cookware and industrial applications where heat fluctuations are common. However, its impact resistance is relatively low because the brittle nature of enamel can lead to chipping or cracking under sudden physical force. Understanding the balance between thermal shock resistance and impact resistance is crucial when selecting enamel for specific uses that demand durability under different stress conditions.

Table of Comparison

| Property | Thermal Shock Resistance | Impact Resistance |

|---|---|---|

| Definition | Ability of enamel to withstand rapid temperature changes without cracking | Ability of enamel to resist physical shocks or sudden force |

| Key Factor | Thermal expansion coefficient and bonding strength | Hardness and toughness of the enamel layer |

| Performance | High resistance prevents cracking or spalling under thermal cycling | High resistance minimizes chipping or surface damage from impacts |

| Testing Methods | Rapid heating and cooling cycles | Impact drop tests or mechanical shock tests |

| Common Applications | Cookware, industrial ovens, heat exchangers | Enamel-coated tools, automotive parts, decorative panels |

| Material Influence | Supports enamel stability on substrates with similar thermal expansion | Requires enamel formulations with enhanced flexibility and toughness |

Understanding Enamel: Composition and Properties

Enamel's unique composition, consisting of finely ground glass fused to a metal substrate, grants it exceptional thermal shock resistance by allowing rapid temperature changes without cracking. Its impact resistance is influenced by the enamel's thickness and the substrate's elasticity, which together absorb and distribute impact forces effectively. Understanding these properties is essential for selecting enamel-coated materials in applications requiring both durability and heat tolerance.

Defining Thermal Shock Resistance in Enamel

Thermal shock resistance in enamel refers to its ability to withstand rapid temperature changes without cracking or delaminating, a critical property for applications involving sudden heat exposure. This resistance is determined by the enamel's thermal expansion coefficient, thickness, and the substrate material's compatibility. High thermal shock resistance enhances enamel durability in cookware, industrial coatings, and electrical insulators by preventing damage from thermal stress.

Exploring Impact Resistance in Enamel Materials

Enamel materials exhibit significant impact resistance due to their hard, glass-like surface that absorbs and disperses energy without cracking. This durability is enhanced by the enamel's ability to deform slightly under stress, preventing brittle failure common in purely ceramic coatings. Impact resistance in enamel is critical for applications requiring both aesthetic appeal and mechanical robustness, such as cookware and industrial coatings.

Key Differences: Thermal Shock vs. Impact Resistance

Thermal shock resistance in enamel refers to its ability to withstand sudden temperature changes without cracking, while impact resistance measures its capacity to absorb physical force or mechanical blows without chipping or breaking. Enamel with high thermal shock resistance typically contains specific formulations and controlled thickness to endure rapid heating or cooling cycles. In contrast, impact resistance depends largely on enamel hardness and flexibility, emphasizing protection against external physical damage rather than temperature fluctuations.

Mechanisms Behind Thermal Shock Failure in Enamel

Thermal shock failure in enamel occurs due to rapid temperature changes causing differential expansion between the glassy enamel layer and the underlying metal substrate, leading to tensile stresses and cracking. The mismatch in thermal expansion coefficients generates microfractures, compromising enamel integrity and reducing thermal shock resistance. Impact resistance, conversely, depends on the enamel's toughness and ability to absorb mechanical energy without fracturing, which is governed by its microstructure and bonding strength rather than thermal properties.

How Enamel Responds to Mechanical Impact

Enamel demonstrates high impact resistance by distributing mechanical force across its hardened surface, reducing the likelihood of cracks or chips upon sudden mechanical impact. Unlike thermal shock resistance, which pertains to enamel's ability to withstand rapid temperature changes without fracturing, impact resistance directly relates to enamel's toughness and capacity to absorb and dissipate energy during physical strikes. This makes enamel particularly effective for protective coatings and decorative surfaces subjected to frequent mechanical stresses.

Factors Influencing Thermal Shock Resistance in Enamel

Thermal shock resistance in enamel primarily depends on its coefficient of thermal expansion, elasticity, and the presence of micro-cracks or internal stresses. Higher thermal expansion mismatch between the enamel and substrate increases susceptibility to thermal shock, while a more elastic enamel composition helps absorb rapid temperature changes. Impact resistance, contrastingly, is influenced by enamel hardness and toughness but does not significantly enhance the enamel's ability to withstand rapid temperature fluctuations.

Enhancing Impact Resistance: Techniques and Additives

Enhancing impact resistance in enamel coatings involves incorporating additives such as zirconia and alumina particles, which improve toughness by distributing stress more evenly across the surface. Techniques like controlled firing schedules optimize the enamel's microstructure, reducing brittleness and increasing durability under sudden impacts. These methods combine to create enamel finishes that withstand mechanical shocks better while maintaining thermal shock resistance.

Applications Requiring High Thermal Shock vs. Impact Resistance

Thermal shock resistance in enamel is crucial for applications such as cookware, laboratory equipment, and furnace linings, where rapid temperature changes occur frequently. Impact resistance is essential for architectural panels, signage, and automotive parts, where physical durability and resistance to mechanical damage are primary concerns. Selecting enamel formulations optimized for thermal shock resistance involves materials with high tensile strength and low thermal expansion, while impact-resistant enamels prioritize toughness and flexibility to absorb mechanical stress.

Choosing the Right Enamel for Extreme Temperature and Impact Conditions

Selecting enamel with high thermal shock resistance ensures durability under rapid temperature changes by preventing cracks and spalling, critical for cookware and industrial applications. Enamels formulated with specific glass compositions, such as borosilicate or alumina additions, enhance impact resistance, protecting surfaces against mechanical stress and abrasion. Balancing thermal shock and impact resistance properties is essential when choosing enamel coatings for environments subjected to extreme temperature fluctuations and frequent physical contact.

Thermal shock resistance vs Impact resistance Infographic

materialdif.com

materialdif.com