Cold enamel, also known as epoxy enamel, is a resin-based coating that cures at room temperature and offers excellent durability and chemical resistance, making it ideal for metal surfaces and detailed artwork. Hot enamel, or vitreous enamel, involves fusing powdered glass to a metal substrate through high-temperature firing, resulting in a glossy, hard, and long-lasting finish often used in jewelry and decorative pieces. The key difference lies in the curing process and finish quality, with hot enamel providing superior toughness and vibrant color depth compared to the more flexible and easier-to-apply cold enamel.

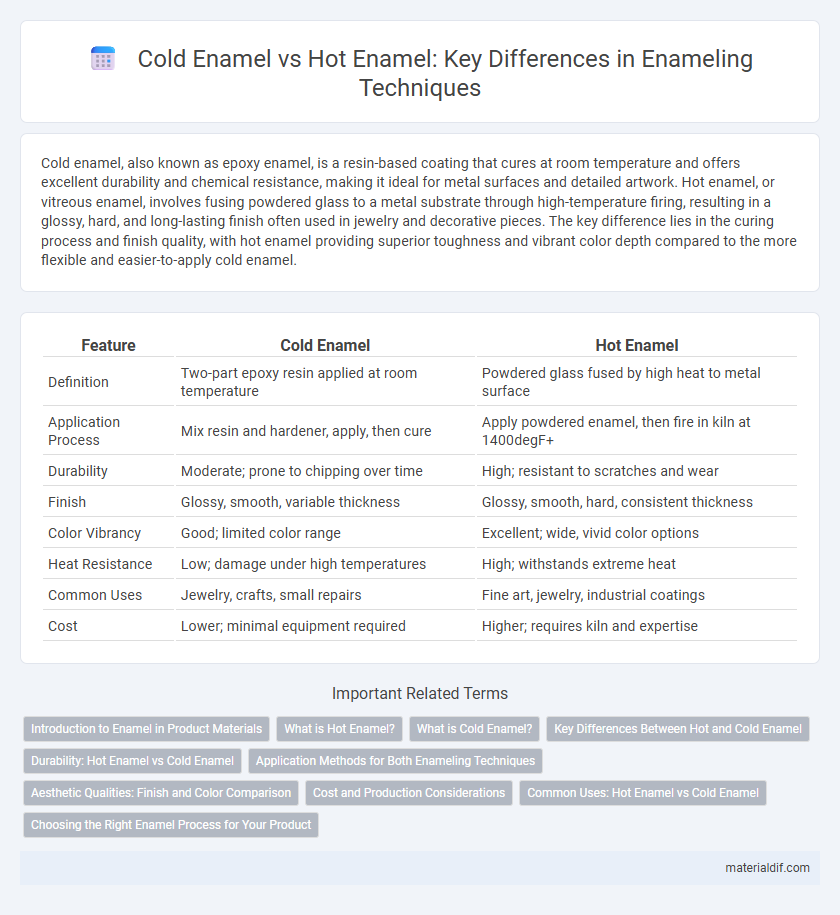

Table of Comparison

| Feature | Cold Enamel | Hot Enamel |

|---|---|---|

| Definition | Two-part epoxy resin applied at room temperature | Powdered glass fused by high heat to metal surface |

| Application Process | Mix resin and hardener, apply, then cure | Apply powdered enamel, then fire in kiln at 1400degF+ |

| Durability | Moderate; prone to chipping over time | High; resistant to scratches and wear |

| Finish | Glossy, smooth, variable thickness | Glossy, smooth, hard, consistent thickness |

| Color Vibrancy | Good; limited color range | Excellent; wide, vivid color options |

| Heat Resistance | Low; damage under high temperatures | High; withstands extreme heat |

| Common Uses | Jewelry, crafts, small repairs | Fine art, jewelry, industrial coatings |

| Cost | Lower; minimal equipment required | Higher; requires kiln and expertise |

Introduction to Enamel in Product Materials

Cold enamel and hot enamel are two popular techniques used in product materials for adding decorative and protective coatings. Cold enamel, also known as resin enamel, uses a colored resin that cures at room temperature, providing a smooth, glossy finish ideal for intricate designs and small batch production. Hot enamel, often referred to as vitreous or cloisonne enamel, involves fusing powdered glass to a metal substrate at high temperatures, resulting in a durable, vibrant, and long-lasting surface commonly used in jewelry and badge manufacturing.

What is Hot Enamel?

Hot enamel is a jewelry technique where powdered glass is fused onto a metal surface by heating to temperatures between 1400degF and 1600degF, creating a durable, glossy coating. This process forms a smooth, glass-like finish that is highly resistant to scratching and chipping compared to cold enamel, which uses epoxy-based resins cured at room temperature. Hot enamel's vibrant colors and longevity make it a preferred choice for high-quality decorative and artistic metalwork.

What is Cold Enamel?

Cold enamel, also known as epoxy resin enamel, is a synthetic coating applied at room temperature without the need for firing or baking. It provides a durable, glossy finish that mimics traditional vitreous enamel while offering greater flexibility and resistance to chipping. Commonly used in jewelry, signage, and decorative items, cold enamel cures through a chemical reaction rather than heat, allowing for easier application on heat-sensitive substrates.

Key Differences Between Hot and Cold Enamel

Hot enamel involves fusing powdered glass to metal at high temperatures, resulting in a durable, glossy finish with vibrant colors resistant to wear and corrosion. Cold enamel, or epoxy enamel, uses liquid resin cured at room temperature, offering more flexibility in application but less heat resistance and durability compared to hot enamel. The primary differences lie in the production process, durability, and temperature tolerance, with hot enamel favored for high-quality jewelry and decorative items, while cold enamel suits cost-effective, versatile uses.

Durability: Hot Enamel vs Cold Enamel

Hot enamel offers superior durability compared to cold enamel due to its firing process, which fuses the enamel to the metal substrate at high temperatures, typically between 700degC and 900degC. This high-heat process results in a harder, more resistant surface capable of withstanding scratches, chips, and fading over time. Cold enamel, applied at room temperature without firing, tends to be softer and more prone to wear, making it less suitable for items that experience frequent handling or exposure to harsh conditions.

Application Methods for Both Enameling Techniques

Cold enamel, also known as epoxy resin enamel, is applied using simple techniques such as brushing, pouring, or injecting, making it ideal for intricate designs and small-scale projects without the need for kilns or firing processes. Hot enamel requires firing in a kiln at temperatures between 1,380 to 1,560 degrees Fahrenheit (750 to 850 degrees Celsius), allowing powdered glass to fuse onto metal surfaces, which results in a durable, glossy finish suitable for jewelry and decorative art. Both methods demand careful preparation of metal surfaces, but hot enameling involves multiple firings for layering colors, whereas cold enameling cures at room temperature within hours.

Aesthetic Qualities: Finish and Color Comparison

Cold enamel offers a smooth, glossy finish with vibrant color retention due to its resin-based composition, making it ideal for detailed and delicate designs. Hot enamel, also known as vitreous enamel, provides a durable, glass-like surface with deeper, richer colors resulting from the high-temperature fusing process. The choice impacts the final aesthetic, with cold enamel favoring brightness and flexibility, while hot enamel excels in depth and long-lasting brilliance.

Cost and Production Considerations

Cold enamel offers a lower production cost due to its simpler application process and faster curing time, making it ideal for small-scale or budget-conscious projects. Hot enamel requires higher temperatures and specialized equipment, increasing energy consumption and overall manufacturing expenses. Production efficiency favors cold enamel for rapid batch processing, while hot enamel excels in durability and finish quality despite its higher costs.

Common Uses: Hot Enamel vs Cold Enamel

Hot enamel is commonly used in jewelry making and decorative art due to its durability and vibrant finish achieved through firing at high temperatures. Cold enamel, a resin-based alternative, is preferred for quick repairs, crafts, and custom accessories where lower heat resistance and faster curing times are essential. Both types serve different purposes, with hot enamel excelling in long-lasting applications and cold enamel favored for versatility and ease of use in everyday projects.

Choosing the Right Enamel Process for Your Product

Cold enamel offers a smooth, durable finish ideal for detailed designs and smaller production runs, while hot enamel provides a more vibrant, glass-like surface suited for larger quantities and premium products. Selecting the right enamel process depends on factors such as production volume, desired finish, durability requirements, and budget constraints. Understanding these differences ensures optimal quality and cost-efficiency tailored to your product's specific needs.

cold enamel vs hot enamel Infographic

materialdif.com

materialdif.com