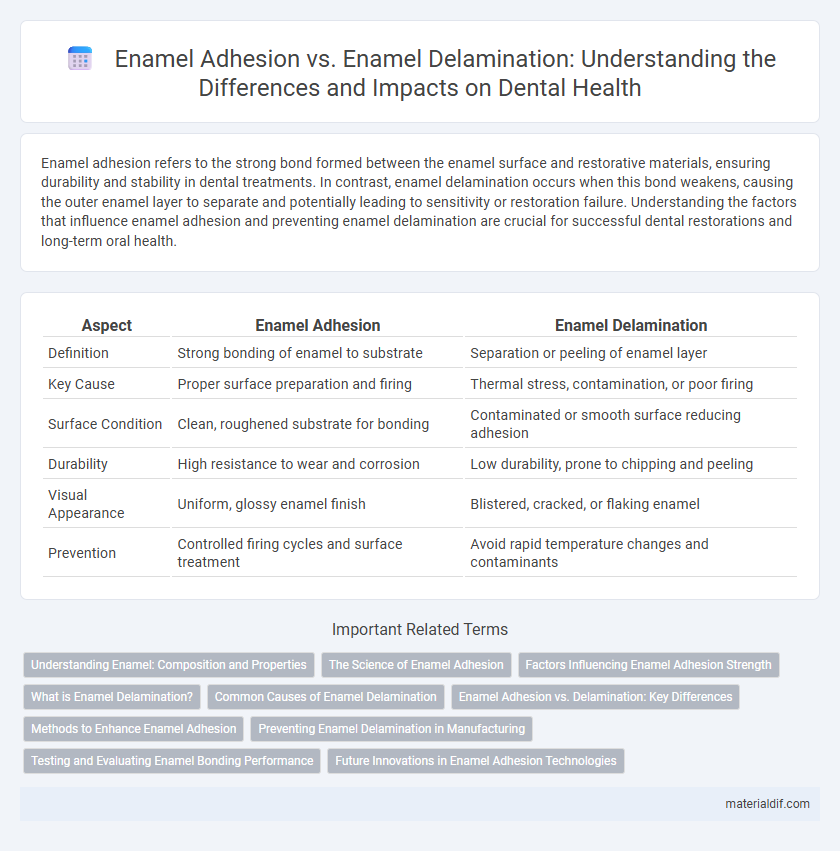

Enamel adhesion refers to the strong bond formed between the enamel surface and restorative materials, ensuring durability and stability in dental treatments. In contrast, enamel delamination occurs when this bond weakens, causing the outer enamel layer to separate and potentially leading to sensitivity or restoration failure. Understanding the factors that influence enamel adhesion and preventing enamel delamination are crucial for successful dental restorations and long-term oral health.

Table of Comparison

| Aspect | Enamel Adhesion | Enamel Delamination |

|---|---|---|

| Definition | Strong bonding of enamel to substrate | Separation or peeling of enamel layer |

| Key Cause | Proper surface preparation and firing | Thermal stress, contamination, or poor firing |

| Surface Condition | Clean, roughened substrate for bonding | Contaminated or smooth surface reducing adhesion |

| Durability | High resistance to wear and corrosion | Low durability, prone to chipping and peeling |

| Visual Appearance | Uniform, glossy enamel finish | Blistered, cracked, or flaking enamel |

| Prevention | Controlled firing cycles and surface treatment | Avoid rapid temperature changes and contaminants |

Understanding Enamel: Composition and Properties

Enamel adhesion depends on the strong chemical bonds formed between hydroxyapatite crystals and adhesive agents, creating a durable interface essential for dental restorations. Enamel delamination occurs when these bonds weaken due to mechanical stress or exposure to acids, leading to the separation of enamel layers. Understanding enamel's highly mineralized composition, primarily of calcium phosphate and its hierarchical microstructure, is crucial for optimizing adhesion techniques and preventing delamination.

The Science of Enamel Adhesion

Enamel adhesion relies on the micro-mechanical interlocking between resin adhesives and the enamel's prismatic structure, enhanced by acid etching that increases surface roughness and surface energy. Enamel delamination occurs when poor adhesive infiltration or inadequate resin polymerization causes separation at the enamel-resin interface, compromising bond strength. Understanding the molecular interactions and surface morphology is critical to optimizing enamel adhesion, reducing the risk of enamel delamination in restorative dentistry.

Factors Influencing Enamel Adhesion Strength

Enamel adhesion strength depends significantly on surface preparation techniques such as etching and cleaning, which enhance mechanical interlocking and chemical bonding. The composition and condition of both the enamel and substrate, including moisture levels and contamination, critically affect adhesion quality. Environmental factors like temperature fluctuations and pH exposure also contribute to the likelihood of enamel delamination by weakening adhesive bonds over time.

What is Enamel Delamination?

Enamel delamination refers to the separation or peeling away of the enamel layer from the underlying tooth structure, often caused by mechanical stress, thermal cycling, or improper bonding techniques. This phenomenon compromises the protective function of enamel, leading to increased tooth sensitivity and susceptibility to decay. Understanding the factors contributing to enamel delamination is crucial for improving adhesive dental materials and ensuring long-lasting enamel restoration.

Common Causes of Enamel Delamination

Enamel delamination commonly occurs due to inadequate surface preparation, which prevents proper adhesion between the enamel coating and the substrate. Thermal stress from rapid temperature changes causes enamel to crack and peel away, undermining its bonding integrity. Mechanical impacts and chemical exposures also contribute to weakening the enamel-substrate interface, leading to delamination.

Enamel Adhesion vs. Delamination: Key Differences

Enamel adhesion refers to the strong, durable bond formed between enamel and restorative materials during dental procedures, ensuring long-lasting repair and resistance to mechanical forces. Enamel delamination involves the separation or peeling away of enamel layers, often caused by mechanical stress, thermal cycling, or inadequate bonding, leading to compromised dental integrity. Understanding the key differences between enamel adhesion and delamination is critical for optimizing restorative techniques and preventing enamel failure.

Methods to Enhance Enamel Adhesion

Enhancing enamel adhesion involves surface treatments such as acid etching with phosphoric acid, which increases enamel porosity and promotes mechanical interlocking with bonding agents. Application of silane coupling agents further improves adhesion by creating a chemical bond between the enamel surface and resin composites. Optimizing these methods significantly reduces the risk of enamel delamination, ensuring durable restorative outcomes in dental procedures.

Preventing Enamel Delamination in Manufacturing

Enamel adhesion relies on strong chemical bonds and surface preparation techniques to ensure durable attachment to metal substrates, minimizing the risk of enamel delamination. Preventing enamel delamination in manufacturing involves optimizing surface cleaning, applying appropriate primers, and controlling firing temperatures to enhance bond strength and thermal expansion compatibility. Consistent quality control and inspection during production reduce defects and increase the longevity of enamel-coated products.

Testing and Evaluating Enamel Bonding Performance

Testing enamel adhesion involves quantifying the bond strength between the enamel coating and underlying substrate, typically using methods such as scratch testing, peel testing, and micro-shear bond strength assays. Enamel delamination is assessed by simulating environmental stresses, thermal cycling, and mechanical fatigue to evaluate the durability and failure modes of the enamel-substrate interface. Advanced surface characterization techniques like scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) further elucidate adhesion mechanisms, enabling optimization of enamel bonding performance.

Future Innovations in Enamel Adhesion Technologies

Future innovations in enamel adhesion technologies emphasize enhancing bond strength and durability to prevent enamel delamination in dental and industrial applications. Advanced surface modification techniques, such as plasma treatment and nanocoatings, improve enamel wettability and chemical bonding, reducing failure rates. Integration of bioactive agents within adhesive formulations promotes remineralization, further stabilizing the enamel interface against mechanical and chemical stresses.

Enamel adhesion vs Enamel delamination Infographic

materialdif.com

materialdif.com