Frit is a pre-melted, granulated glass used in enamel to provide color and durability, while flux is a substance that lowers the melting point of the glass and metal during firing, ensuring proper adhesion and fusion. Frit typically contains a mixture of silica, fluxes, and colorants that control the enamel's texture and finish. Flux plays a crucial role in facilitating the bonding process by promoting smooth melting and preventing defects in the final enamel coating.

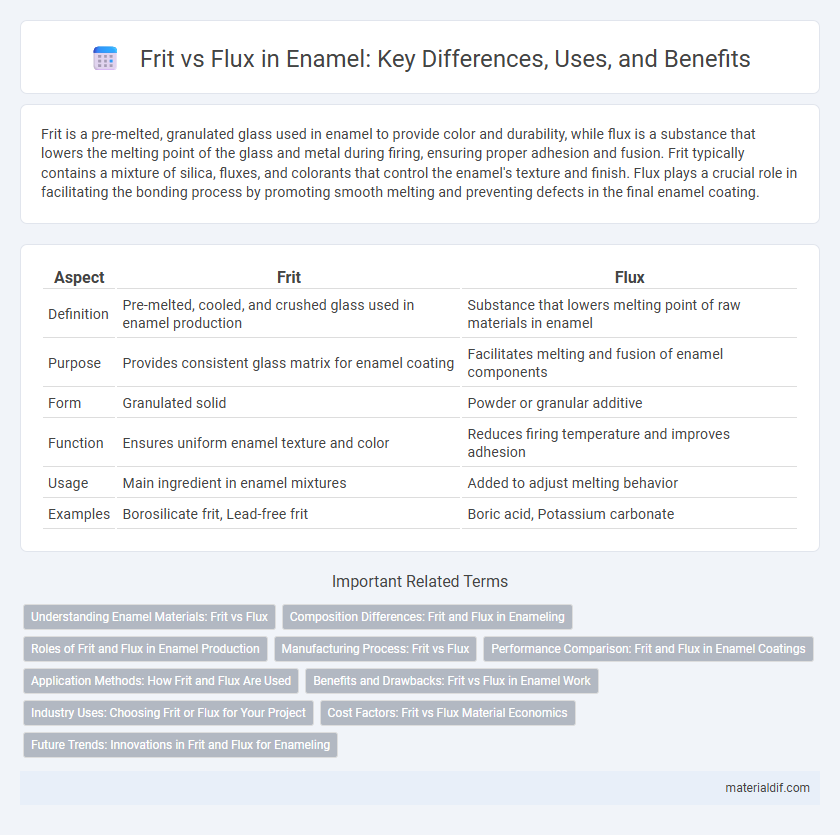

Table of Comparison

| Aspect | Frit | Flux |

|---|---|---|

| Definition | Pre-melted, cooled, and crushed glass used in enamel production | Substance that lowers melting point of raw materials in enamel |

| Purpose | Provides consistent glass matrix for enamel coating | Facilitates melting and fusion of enamel components |

| Form | Granulated solid | Powder or granular additive |

| Function | Ensures uniform enamel texture and color | Reduces firing temperature and improves adhesion |

| Usage | Main ingredient in enamel mixtures | Added to adjust melting behavior |

| Examples | Borosilicate frit, Lead-free frit | Boric acid, Potassium carbonate |

Understanding Enamel Materials: Frit vs Flux

Frit is a pre-melted, cooled, and granulated glass product used in enamel production to ensure consistent composition and melting properties, while flux refers to raw materials added to lower the melting temperature of the enamel mixture. Frit provides stability and homogeneity in enamel coatings, reducing defects such as blistering and pinholes, whereas fluxes like boron oxide or sodium oxide facilitate melting and bonding but can vary in reactivity. Understanding the distinct roles of frit and flux is essential for optimizing enamel formulas for durability, adhesion, and surface finish.

Composition Differences: Frit and Flux in Enameling

Frit in enameling is a specially processed glass, ground and melted to form a stable, non-reactive material that fuses smoothly onto metal surfaces. Flux, on the other hand, is primarily composed of mineral oxides like borates or phosphates that lower the melting point of the frit, facilitating adhesion and flow during firing. The key compositional difference lies in frit being a vitrified glass substance, while flux acts as a chemical agent enhancing the melting behavior and surface bonding of the enamel.

Roles of Frit and Flux in Enamel Production

Frit serves as a pre-melted glass material that provides essential oxides to create a stable, durable enamel coating, ensuring proper melting and adherence to the metal substrate. Flux acts as a melting agent that lowers the melting temperature of raw materials in enamel production, enabling smooth fusion and fluidity during firing. Together, frit and flux balance chemical composition and thermal properties, optimizing enamel formation and surface quality.

Manufacturing Process: Frit vs Flux

Frit is a pre-melted, ground glass used in the enamel manufacturing process to achieve consistent melting and reduce defects, while flux consists of raw mineral materials added directly to the enamel batch to lower the melting temperature. The use of frit allows precise control over chemical composition and prevents volatilization of certain elements during firing, enhancing enamel durability. In contrast, flux materials can introduce variability and require careful blending to maintain product quality in industrial enamel production.

Performance Comparison: Frit and Flux in Enamel Coatings

Frit and flux are crucial components in enamel coatings that influence durability and adhesion. Frit, a pre-melted glass mixture, offers superior chemical resistance and thermal stability compared to flux, which lowers melting points but may reduce hardness and scratch resistance. Performance differences between frit and flux directly impact the enamel's longevity and protective qualities in industrial applications.

Application Methods: How Frit and Flux Are Used

Frit is primarily applied as a ground powder or paste directly onto the surface to be enameled, allowing precise control over thickness and color distribution before firing. Flux, often added to frit, serves as a melting agent to lower the melting point of the enamel, enhancing flow and adhesion during firing. Application methods for flux vary from mixing with enamel powders to coating substrates, optimizing the fusion process in kiln or torch firing techniques.

Benefits and Drawbacks: Frit vs Flux in Enamel Work

Frit provides a controlled and consistent melting point, resulting in smoother, more uniform enamel surfaces ideal for fine detail work, while its manufacturing process reduces impurities that can cause defects. Flux, typically raw minerals, offers greater flexibility and cost-efficiency but may introduce unpredictable melting behavior and impurities that affect enamel clarity and durability. Choosing frit enhances precision and repeatability in enamel work, whereas flux allows for experimentation at a trade-off with surface quality and consistency.

Industry Uses: Choosing Frit or Flux for Your Project

Frit offers consistent chemical composition and is preferred in industrial glass production for its stability and ease of melting, making it ideal for high-volume applications requiring uniform results. Flux, composed of raw materials like minerals and salts, lowers melting temperatures but may introduce variability, useful in custom or small-batch enamel projects where flexibility is key. Selecting frit or flux depends on project scale, desired enamel properties, and industry standards, with frit favored in mass production and flux suited for artisanal or specialized tasks.

Cost Factors: Frit vs Flux Material Economics

Frit materials generally incur higher production costs due to the complex melting and cooling processes required to achieve their glassy, stable composition, whereas fluxes are typically less expensive raw materials used to lower the melting point in enamel formulations. The economics of frit versus flux hinge on factors such as raw material sourcing, energy consumption during manufacture, and batch consistency, with frits offering superior durability and chemical resistance at a premium price. Cost efficiency in enamel production often balances the higher upfront investment in frits against the performance benefits and longer lifespan they provide compared to conventional flux materials.

Future Trends: Innovations in Frit and Flux for Enameling

Emerging innovations in frit and flux formulations are driving enhanced durability, color vibrancy, and eco-friendly properties in enameling applications. Advanced nanotechnology integration enables frits with improved melting profiles and reduced environmental impact, while fluxes increasingly incorporate sustainable raw materials to optimize firing efficiency and surface smoothness. These future trends position frit and flux development at the forefront of sustainable and high-performance enamel manufacturing.

Frit vs Flux Infographic

materialdif.com

materialdif.com