Continuous enamel forms a uniform, uninterrupted layer over the tooth surface, providing consistent protection against decay and mechanical wear. Discontinuous enamel, however, exhibits gaps or variations in thickness, which may increase vulnerability to cavities and structural damage. Understanding the differences in enamel continuity aids in assessing dental health risks and tailoring preventive treatments.

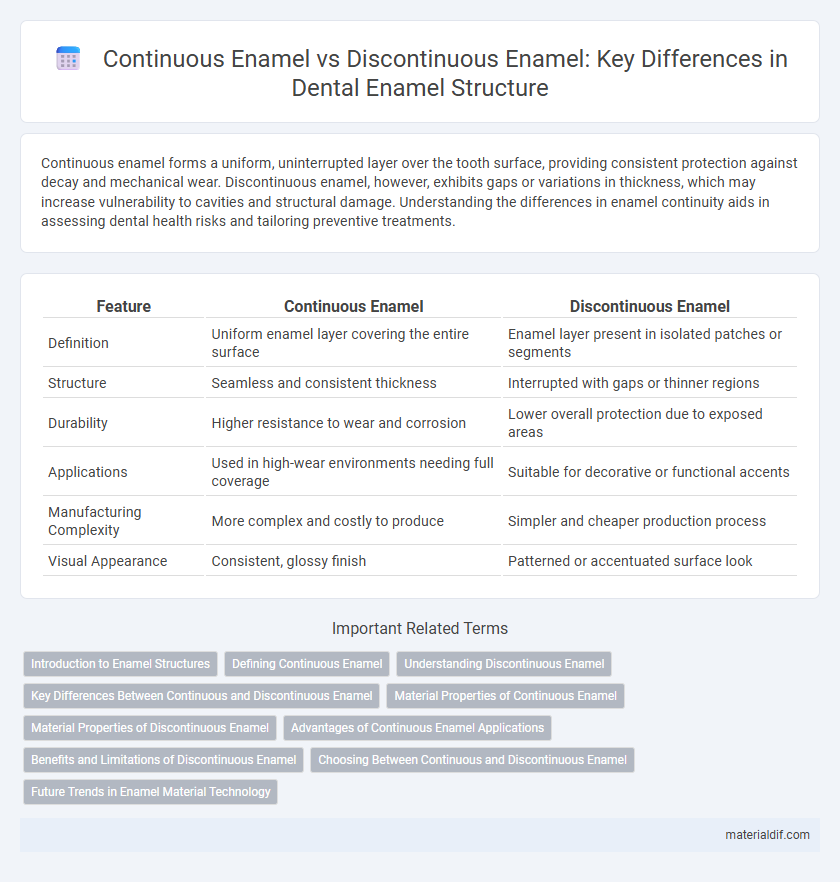

Table of Comparison

| Feature | Continuous Enamel | Discontinuous Enamel |

|---|---|---|

| Definition | Uniform enamel layer covering the entire surface | Enamel layer present in isolated patches or segments |

| Structure | Seamless and consistent thickness | Interrupted with gaps or thinner regions |

| Durability | Higher resistance to wear and corrosion | Lower overall protection due to exposed areas |

| Applications | Used in high-wear environments needing full coverage | Suitable for decorative or functional accents |

| Manufacturing Complexity | More complex and costly to produce | Simpler and cheaper production process |

| Visual Appearance | Consistent, glossy finish | Patterned or accentuated surface look |

Introduction to Enamel Structures

Continuous enamel forms a uniform, seamless layer protecting the tooth surface, composed of tightly packed hydroxyapatite crystals arranged in enamel rods. Discontinuous enamel exhibits gaps or interruptions in this mineralized layer, often due to developmental defects or pathological conditions. Understanding these enamel structures is crucial for diagnosing enamel hypoplasia and optimizing restorative dental treatments.

Defining Continuous Enamel

Continuous enamel forms a uniform, uninterrupted layer over the tooth surface, providing superior protection against decay and mechanical wear. This type of enamel is characterized by its consistent mineral density and structural integrity, which enhance tooth durability and resistance to acid erosion. Continuous enamel contrasts with discontinuous enamel, where gaps or variations in enamel thickness create vulnerabilities that compromise tooth health.

Understanding Discontinuous Enamel

Discontinuous enamel refers to enamel layers that are interrupted or broken, resulting in gaps or irregularities on the tooth surface, contrasting with the uniform, unbroken structure seen in continuous enamel. This type of enamel often occurs due to developmental anomalies, enamel hypoplasia, or mechanical damage, leading to increased susceptibility to decay and wear. Understanding the formation and properties of discontinuous enamel is critical for dental diagnostics and developing targeted preventive or restorative treatments.

Key Differences Between Continuous and Discontinuous Enamel

Continuous enamel forms a uniform, uninterrupted layer on tooth surfaces, providing consistent protection against decay and wear, while discontinuous enamel appears as irregular, patchy areas often due to developmental disturbances or enamel hypoplasia. The key differences lie in the completeness and thickness of the enamel layer, where continuous enamel offers superior durability and resistance, and discontinuous enamel is prone to increased sensitivity and susceptibility to caries. Clinically, identifying discontinuous enamel is crucial for preventive dental treatments and restoration planning to enhance enamel strength and longevity.

Material Properties of Continuous Enamel

Continuous enamel exhibits superior adhesion and uniform thickness, enhancing durability and resistance to chemical corrosion. Its homogeneous composition provides excellent surface hardness and improved thermal stability compared to discontinuous enamel. This results in a consistent protective layer ideal for industrial and decorative applications requiring long-lasting performance.

Material Properties of Discontinuous Enamel

Discontinuous enamel exhibits enhanced fracture resistance due to its segmented microstructure, which dissipates stress more effectively than continuous enamel. The presence of microgaps within discontinuous enamel increases its toughness and reduces crack propagation, improving its durability under mechanical load. This enamel type also demonstrates superior flexibility and resilience, making it advantageous in applications requiring impact absorption.

Advantages of Continuous Enamel Applications

Continuous enamel provides superior protective coating by offering uniform coverage, reducing the risk of corrosion and mechanical wear on metal surfaces. Its seamless nature enhances durability and extends the lifespan of industrial equipment and household appliances. Continuous enamel also ensures consistent aesthetic quality, improving resistance to staining and chemical damage in various applications.

Benefits and Limitations of Discontinuous Enamel

Discontinuous enamel provides enhanced structural flexibility, allowing teeth to better absorb mechanical stress without cracking, which is beneficial in areas subjected to high occlusal forces. Its primary limitation lies in reduced overall hardness and wear resistance compared to continuous enamel, potentially leading to faster enamel degradation over time. This trade-off requires balancing durability with resilience in dental restoration and biomimetic material design.

Choosing Between Continuous and Discontinuous Enamel

Choosing between continuous and discontinuous enamel depends primarily on the desired protection and aesthetic finish. Continuous enamel offers a uniform, durable coating ideal for corrosion resistance and long-lasting surfaces in industrial applications. Discontinuous enamel provides targeted coverage, suitable for decorative purposes or components requiring partial shielding without added weight.

Future Trends in Enamel Material Technology

Future trends in enamel material technology emphasize the development of continuous enamel coatings that offer superior durability, corrosion resistance, and uniform surface quality compared to traditional discontinuous enamel. Advances in nanotechnology and smart enamel formulations aim to enhance mechanical strength and self-healing properties, reducing maintenance costs and extending lifespan in industrial applications. Research is also focused on environmentally friendly enamel processes that minimize energy consumption and toxic emissions during manufacturing.

Continuous enamel vs Discontinuous enamel Infographic

materialdif.com

materialdif.com