Enamel layering provides precise control over the design by applying multiple, thin coats of enamel, resulting in a textured, vibrant finish with enhanced depth and detail. Enamel dipping immerses the entire piece into liquid enamel, producing a smooth, even coating that is ideal for consistent color coverage but lacks the fine detail achievable with layering. Choosing between layering and dipping depends on the desired aesthetic, complexity of the design, and durability requirements of the enamel finish.

Table of Comparison

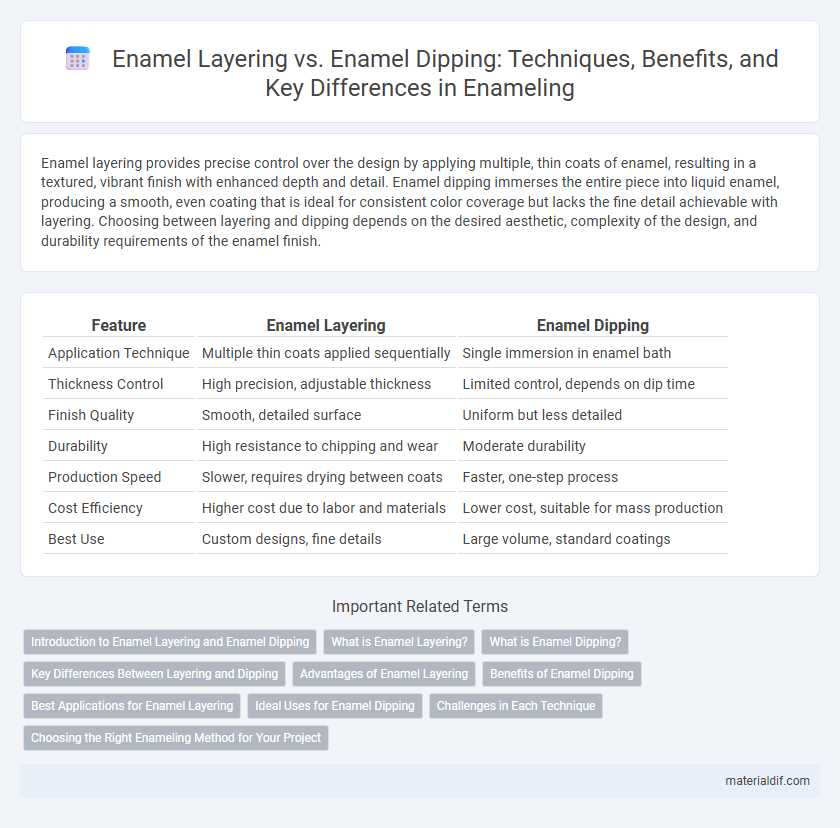

| Feature | Enamel Layering | Enamel Dipping |

|---|---|---|

| Application Technique | Multiple thin coats applied sequentially | Single immersion in enamel bath |

| Thickness Control | High precision, adjustable thickness | Limited control, depends on dip time |

| Finish Quality | Smooth, detailed surface | Uniform but less detailed |

| Durability | High resistance to chipping and wear | Moderate durability |

| Production Speed | Slower, requires drying between coats | Faster, one-step process |

| Cost Efficiency | Higher cost due to labor and materials | Lower cost, suitable for mass production |

| Best Use | Custom designs, fine details | Large volume, standard coatings |

Introduction to Enamel Layering and Enamel Dipping

Enamel layering involves applying multiple thin coats of enamel to achieve depth, gloss, and color richness, allowing for precise control over the finish's texture and appearance. Enamel dipping, on the other hand, is a technique where the object is submerged in enamel liquid, creating a uniform, durable, and smooth coating in a single process. Both methods are essential in ceramics and metalwork, with layering offering detailed customization while dipping provides efficient, consistent coverage.

What is Enamel Layering?

Enamel layering is a precise decorative technique where multiple thin layers of enamel powder are carefully applied and fired sequentially to build depth and intricate designs on metal surfaces. This method allows for greater control over color gradients, translucency, and texture, resulting in a rich, multi-dimensional finish compared to enamel dipping. Enamel layering is commonly used in fine jewelry and artisan metalwork to achieve detailed and vibrant patterns that are not possible with uniform dipping applications.

What is Enamel Dipping?

Enamel dipping is a process where a metal object is submerged into a liquid enamel slurry to create a uniform coating that adheres seamlessly to the surface. This technique ensures consistent thickness and smooth coverage, making it ideal for complex shapes and intricate designs. Unlike enamel layering, which involves applying multiple coats manually, enamel dipping provides efficiency and durability by enveloping the object in a single, continuous enamel layer.

Key Differences Between Layering and Dipping

Enamel layering involves the precise application of multiple thin coats to build depth, clarity, and color variation, enhancing the final finish's richness and texture. Enamel dipping submerges the item entirely in a liquid enamel, producing a uniform, consistent coating ideal for mass production but with less control over intricate details. The key difference lies in layering's ability to create detailed effects through controlled application versus dipping's efficiency in achieving smooth, even coverage quickly.

Advantages of Enamel Layering

Enamel layering offers precise control over thickness and color gradients, resulting in intricate designs with enhanced visual depth and durability. This technique allows for multiple firings, which improve the enamel's adherence and resistance to chipping compared to dipping methods. Fine detail and customized color blending make enamel layering superior for high-quality jewelry and artisanal pieces.

Benefits of Enamel Dipping

Enamel dipping offers superior uniformity by fully submerging objects, ensuring a consistent and durable protective coating compared to enamel layering. This method enhances corrosion resistance and reduces surface imperfections, resulting in longer-lasting finishes ideal for industrial and decorative applications. Enamel dipping also increases production efficiency by providing faster application and curing times than traditional layering techniques.

Best Applications for Enamel Layering

Enamel layering is ideal for detailed, multi-color designs requiring precise control and depth, commonly used in fine jewelry and decorative art pieces. This technique allows for a richer texture and gradation of colors compared to enamel dipping, making it perfect for intricate patterns and artistic effects. Layering is preferred in applications where aesthetic complexity and durability are critical, such as custom jewelry and high-end enamelware.

Ideal Uses for Enamel Dipping

Enamel dipping is ideal for creating a durable, uniform coating on complex-shaped items, providing excellent protection against corrosion and wear. This method is especially useful for industrial parts, tools, and appliances needing a consistent finish without intricate detailing. Enamel layering is better suited for decorative applications requiring multiple colors and detailed designs, whereas dipping emphasizes functional durability.

Challenges in Each Technique

Enamel layering presents challenges such as achieving uniform thickness and preventing cracking during firing, which demand precise control over application and kiln temperature. Enamel dipping often struggles with issues like uneven coating and excessive glaze buildup resulting in drips or pooling, requiring careful timing and consistency in immersion. Both techniques require skilled handling to avoid defects like pinholes, blistering, or color distortion, impacting the final aesthetic and durability of the enamel finish.

Choosing the Right Enameling Method for Your Project

Choosing the right enameling method depends on the desired finish and project complexity; enamel layering offers precise control for detailed designs and vibrant color gradients, while enamel dipping provides uniform coverage ideal for simple shapes and mass production. Layering involves applying multiple thin coats with firing between each, enhancing depth and texture, whereas dipping involves submerging the piece in enamel slurry for a quick, consistent coat. Assessing factors like color intensity, texture preference, and production scale ensures optimal selection between these techniques for high-quality enamel results.

Enamel Layering vs Enamel Dipping Infographic

materialdif.com

materialdif.com