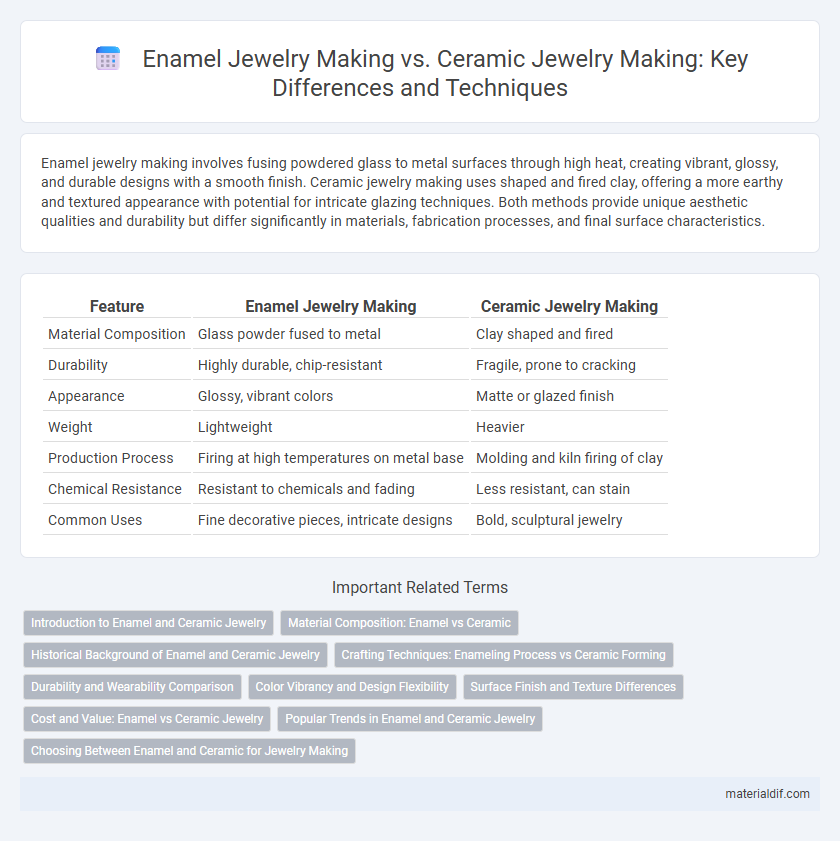

Enamel jewelry making involves fusing powdered glass to metal surfaces through high heat, creating vibrant, glossy, and durable designs with a smooth finish. Ceramic jewelry making uses shaped and fired clay, offering a more earthy and textured appearance with potential for intricate glazing techniques. Both methods provide unique aesthetic qualities and durability but differ significantly in materials, fabrication processes, and final surface characteristics.

Table of Comparison

| Feature | Enamel Jewelry Making | Ceramic Jewelry Making |

|---|---|---|

| Material Composition | Glass powder fused to metal | Clay shaped and fired |

| Durability | Highly durable, chip-resistant | Fragile, prone to cracking |

| Appearance | Glossy, vibrant colors | Matte or glazed finish |

| Weight | Lightweight | Heavier |

| Production Process | Firing at high temperatures on metal base | Molding and kiln firing of clay |

| Chemical Resistance | Resistant to chemicals and fading | Less resistant, can stain |

| Common Uses | Fine decorative pieces, intricate designs | Bold, sculptural jewelry |

Introduction to Enamel and Ceramic Jewelry

Enamel jewelry making uses powdered glass fused to metal surfaces at high temperatures, creating vibrant, durable designs often seen in cloisonne and champleve techniques. Ceramic jewelry making involves shaping and firing clay or porcelain, allowing for intricate textures and glaze finishes that provide a distinct aesthetic compared to the glossy, colorful enamel. Both methods offer unique artistic possibilities, with enamel prized for its brilliance and ceramics favored for versatility in form and surface treatment.

Material Composition: Enamel vs Ceramic

Enamel jewelry making involves fusing powdered glass to metal surfaces, typically copper, silver, or gold, creating a smooth, durable, and vividly colored coating. Ceramic jewelry making uses refined clay compounds fired at high temperatures to form a solid, often porous structure that can be glazed for added color and texture. Enamel's glassy, non-porous finish contrasts with ceramic's earthy, sometimes matte surface, affecting both durability and aesthetic versatility in jewelry design.

Historical Background of Enamel and Ceramic Jewelry

Enamel jewelry making dates back to ancient Egypt and the Byzantine Empire, where artisans used vitreous enamel to create vibrant, durable designs by fusing powdered glass to metal surfaces at high temperatures. Ceramic jewelry, with roots in prehistoric pottery and ancient Mesopotamian cultures, involves shaping and firing clay to create unique, earthy accessories that often feature glaze finishes for color and protection. Both techniques have evolved through centuries, reflecting cultural significance and technological advancements in decorative art forms.

Crafting Techniques: Enameling Process vs Ceramic Forming

Enamel jewelry making involves fusing powdered glass onto metal surfaces through high-temperature firing, creating a durable, glossy finish with vibrant colors. Ceramic jewelry making relies on shaping clay and then firing it in a kiln to achieve solid forms, often followed by glazing for texture and color enhancement. Enameling emphasizes precision in metal preparation and controlled kiln temperatures, while ceramic forming prioritizes mold creation and clay consistency for structural integrity.

Durability and Wearability Comparison

Enamel jewelry offers superior durability due to its glass-like surface that resists scratching and fading, making it ideal for daily wear. Ceramic jewelry, while highly scratch-resistant and lightweight, can be more prone to chipping or cracking under impact. Both materials provide comfortable wearability, but enamel's resilience ensures longer-lasting vibrancy compared to ceramic's delicate nature.

Color Vibrancy and Design Flexibility

Enamel jewelry making offers superior color vibrancy with its brilliant, glass-like finish that resists fading and provides a wide spectrum of vivid hues. Ceramic jewelry making allows for intricate shapes and textures but often results in more muted colors due to firing limitations and surface glazing techniques. The design flexibility in enamel is higher for detailed color work and layering, while ceramics excel in sculptural and tactile designs.

Surface Finish and Texture Differences

Enamel jewelry making produces a glossy, vibrant surface finish with a smooth texture, achieved by fusing powdered glass to metal surfaces at high temperatures. In contrast, ceramic jewelry making often results in a matte or satin finish with a slightly rougher, more porous texture due to the clay and firing process. The enamel's sleek, polished look enhances color intensity, while ceramic offers a tactile, organic feel with subtle surface irregularities.

Cost and Value: Enamel vs Ceramic Jewelry

Enamel jewelry making typically requires higher-quality metals and specialized kilns, resulting in greater initial costs compared to ceramic jewelry, which uses more affordable clay and standard ovens. The durable, vibrant finish of enamel often commands higher market value due to its long-lasting shine and resistance to wear, whereas ceramic jewelry may be more prone to chipping but offers greater design flexibility at a lower price point. Consumers seeking investment pieces tend to favor enamel for its combination of aesthetic appeal and enduring worth, while ceramic jewelry appeals to budget-conscious buyers prioritizing creative expression.

Popular Trends in Enamel and Ceramic Jewelry

Enamel jewelry making showcases vibrant, glossy finishes through fusing powdered glass onto metal, making it a popular choice for intricate, colorful designs in contemporary fashion. Ceramic jewelry trends emphasize unique textures and organic shapes, leveraging the material's versatility for bold, handcrafted statement pieces. Both styles enjoy growing popularity, with enamel favored for detailed, durable art pieces and ceramics appreciated for artistic, earthy aesthetics.

Choosing Between Enamel and Ceramic for Jewelry Making

Choosing between enamel and ceramic for jewelry making depends on durability, appearance, and working techniques. Enamel offers vibrant, glassy finishes with high resistance to scratching and fading, ideal for intricate designs requiring precision and longevity. Ceramic jewelry, while offering a diverse range of textures and colors, tends to be heavier and more fragile, making it suitable for bold statement pieces rather than delicate, everyday wear.

Enamel Jewelry Making vs Ceramic Jewelry Making Infographic

materialdif.com

materialdif.com