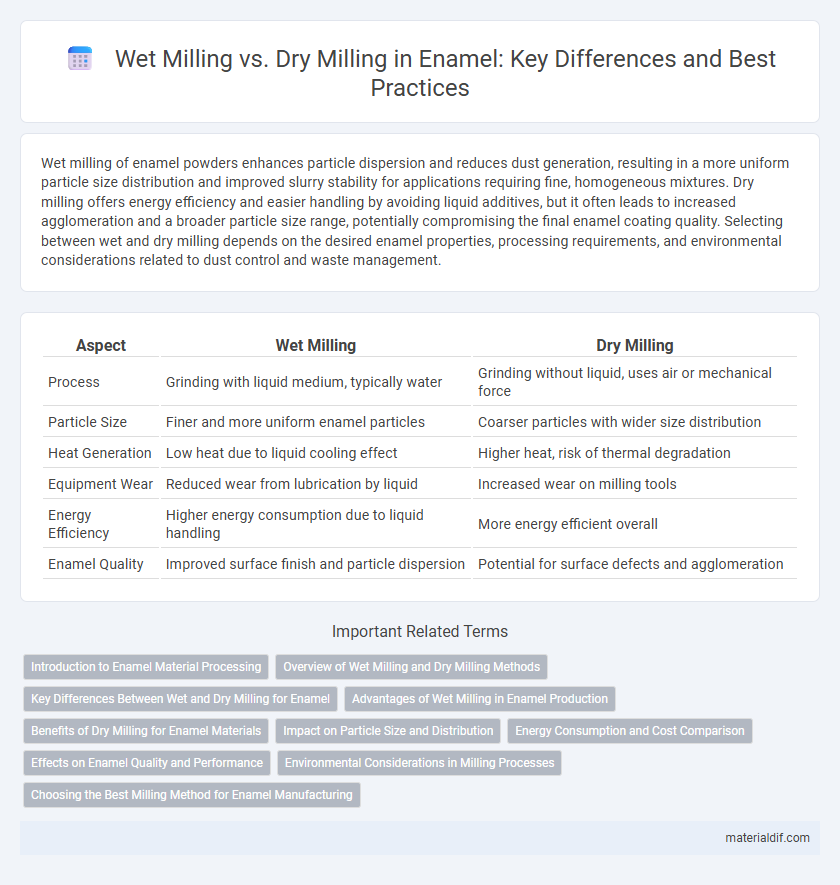

Wet milling of enamel powders enhances particle dispersion and reduces dust generation, resulting in a more uniform particle size distribution and improved slurry stability for applications requiring fine, homogeneous mixtures. Dry milling offers energy efficiency and easier handling by avoiding liquid additives, but it often leads to increased agglomeration and a broader particle size range, potentially compromising the final enamel coating quality. Selecting between wet and dry milling depends on the desired enamel properties, processing requirements, and environmental considerations related to dust control and waste management.

Table of Comparison

| Aspect | Wet Milling | Dry Milling |

|---|---|---|

| Process | Grinding with liquid medium, typically water | Grinding without liquid, uses air or mechanical force |

| Particle Size | Finer and more uniform enamel particles | Coarser particles with wider size distribution |

| Heat Generation | Low heat due to liquid cooling effect | Higher heat, risk of thermal degradation |

| Equipment Wear | Reduced wear from lubrication by liquid | Increased wear on milling tools |

| Energy Efficiency | Higher energy consumption due to liquid handling | More energy efficient overall |

| Enamel Quality | Improved surface finish and particle dispersion | Potential for surface defects and agglomeration |

Introduction to Enamel Material Processing

Wet milling in enamel material processing enhances particle dispersion and reduces heat generation, preserving enamel quality and uniformity. Dry milling offers higher efficiency and lower operational costs but risks overheating and increased wear on milling equipment, potentially impacting enamel surface integrity. Selecting the appropriate milling method depends on balancing enamel composition, desired properties, and production scale requirements.

Overview of Wet Milling and Dry Milling Methods

Wet milling involves grinding materials with the presence of liquid, typically water, to produce a fine slurry that enhances particle size reduction and reduces heat generation, making it suitable for heat-sensitive enamel components. Dry milling, on the other hand, grinds materials without liquid, resulting in a powder form that can sometimes cause higher temperatures and potential agglomeration of enamel powders. Both methods impact the physical properties and quality of enamel coatings, with wet milling offering better uniformity and dry milling providing faster processing times.

Key Differences Between Wet and Dry Milling for Enamel

Wet milling for enamel typically involves the use of liquid mediums to reduce particle size, resulting in finer, more uniform enamel powders with improved dispersion properties. Dry milling, by contrast, uses mechanical forces without liquids, often producing coarser particles and increased dust generation, which can affect enamel coating quality and worker safety. Wet milling enhances enamel homogeneity and gloss, while dry milling is more energy-efficient but may require additional processing to achieve similar surface smoothness.

Advantages of Wet Milling in Enamel Production

Wet milling in enamel production enhances particle size reduction and uniform dispersion, leading to improved coating smoothness and durability. The presence of liquid minimizes dust generation, ensuring safer handling and reducing environmental impact. This method also promotes better homogeneity in the enamel mixture, resulting in superior surface finish and increased resistance to chipping and wear.

Benefits of Dry Milling for Enamel Materials

Dry milling of enamel materials offers enhanced precision and surface finish compared to wet milling, reducing the risk of water-induced defects and contamination. It promotes higher material stability by eliminating moisture exposure, which is critical for maintaining the structural integrity and color consistency of enamel. This method also improves efficiency by simplifying the machining process, minimizing equipment corrosion, and reducing the need for post-processing drying steps.

Impact on Particle Size and Distribution

Wet milling of enamel materials typically results in finer particle sizes with a narrower, more uniform distribution compared to dry milling due to the presence of a liquid medium that reduces agglomeration and prevents heat buildup. Dry milling often produces coarser particles with broader size distribution, which can negatively affect the consistency and surface quality of the enamel coating. Optimizing particle size and distribution through wet milling enhances enamel flow properties and final finish smoothness.

Energy Consumption and Cost Comparison

Wet milling of enamel particles typically consumes less energy than dry milling due to reduced friction and lower grinding resistance, resulting in cost savings. Although wet milling entails additional expenses for water management and drying processes, overall operational costs often remain lower compared to dry milling. Energy efficiency and reduced equipment wear contribute to wet milling's cost-effectiveness in enamel powder production.

Effects on Enamel Quality and Performance

Wet milling preserves enamel microstructure by minimizing heat generation and preventing enamel dehydration, resulting in enhanced mechanical strength and improved wear resistance. Dry milling often induces thermal stress and microcracks in enamel surfaces, compromising durability and increasing the risk of chipping. Optimizing milling conditions to reduce heat exposure is crucial for maintaining enamel integrity and ensuring long-lasting performance in restorative applications.

Environmental Considerations in Milling Processes

Wet milling of enamel materials significantly reduces airborne dust emissions and particulate pollution compared to dry milling, contributing to improved air quality and worker safety. The use of water as a lubricant and coolant minimizes heat generation, lowering energy consumption and reducing the environmental footprint of the milling process. However, wet milling produces wastewater requiring proper treatment to prevent contamination of local water sources, making effective effluent management critical for environmental compliance.

Choosing the Best Milling Method for Enamel Manufacturing

Wet milling offers superior particle dispersion and reduced dust generation, making it ideal for enamel manufacturing where uniformity and safety are critical. Dry milling is more energy-efficient and suitable for harder materials but may cause agglomeration, affecting enamel texture and quality. Selecting the best milling method depends on the desired enamel properties, production scale, and material characteristics to optimize performance and cost-effectiveness.

Wet milling vs Dry milling Infographic

materialdif.com

materialdif.com